Epoxy resin combination and coating combination containing the same

A technology of epoxy resin and composition, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of coating operability, processability reduction, weak solvent solubility reduction, and difficulty in modifying epoxy resin, etc., to achieve The effects of a wide degree of freedom of choice, good processability, and excellent coating workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

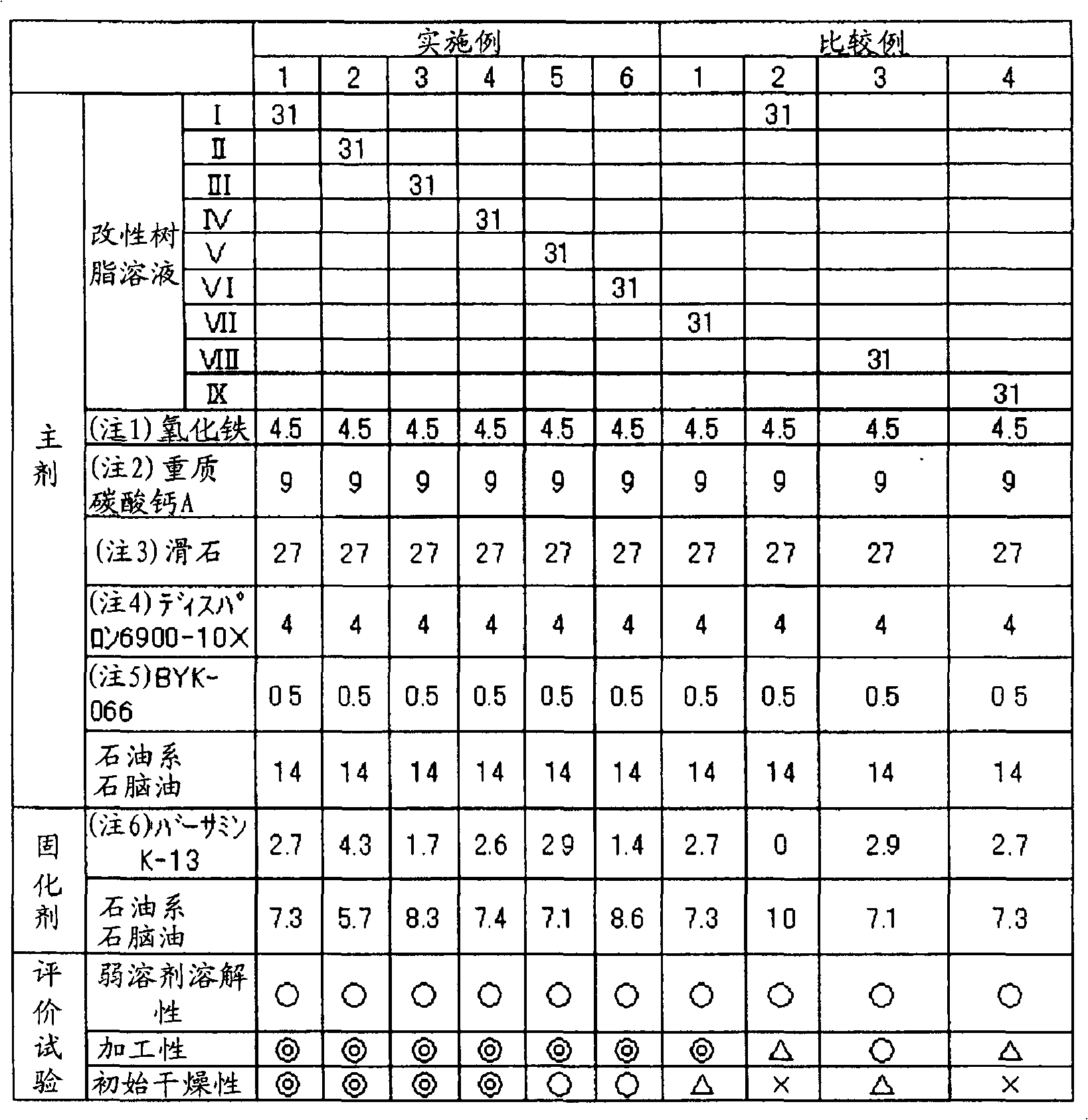

[0058] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In addition, "parts" and "%" in the following examples represent "parts by mass" and "% by mass", respectively.

manufacture example 1

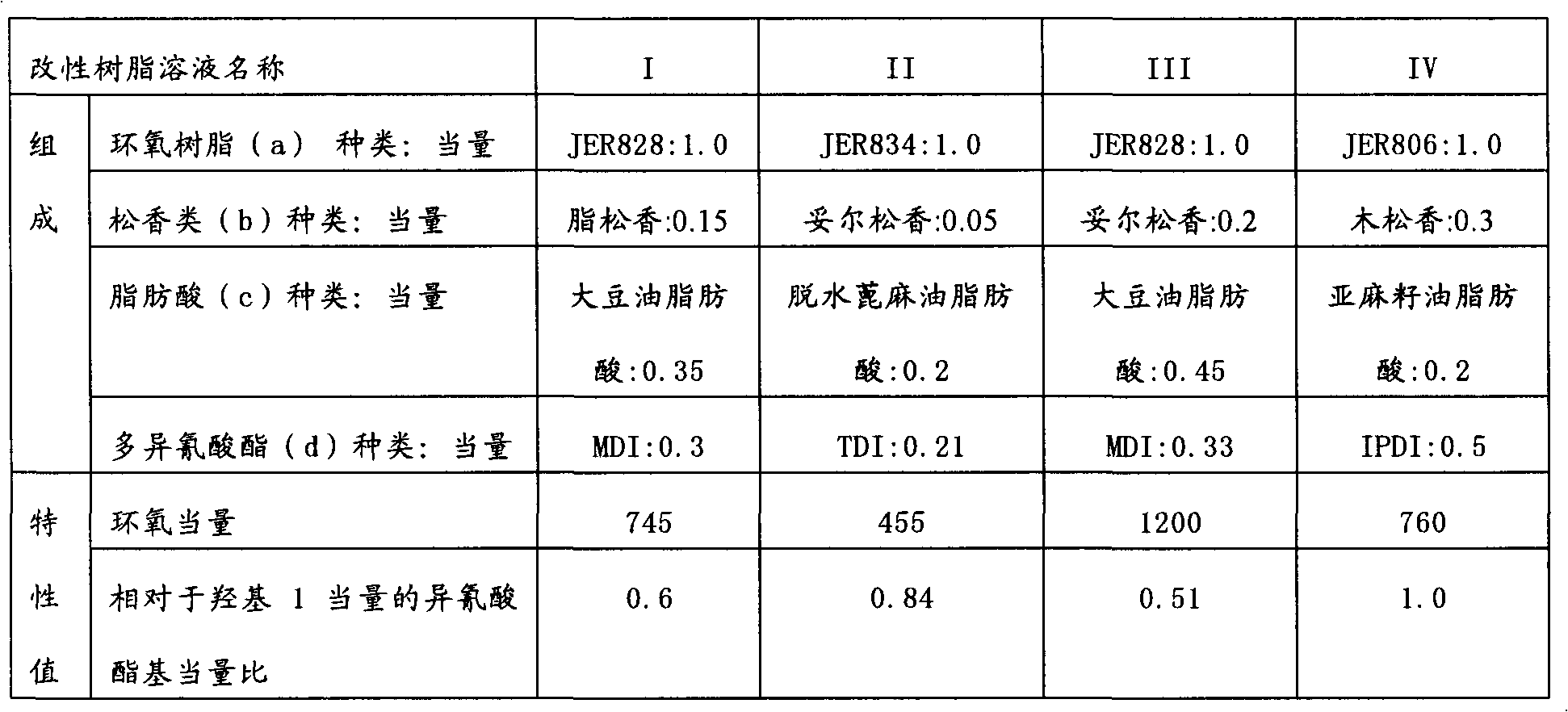

[0061] In a reaction device having a heating device, a stirrer, and a nitrogen introduction pipe, 185 parts of "JER828" (trade name, manufactured by Japan Epoch Resin Co., Ltd., a bisphenol A type epoxy resin with an epoxy equivalent of 185) and 51 parts of gum rosin were charged. part and 98 parts of soybean oil fatty acid, heated to 160°C while stirring under a dry nitrogen atmosphere, and reacted until the acid value was 0. After adding 160 parts of "Swazel 1000" (trade name, manufactured by Cosmo Petroleum Co., Ltd., boiling point: 162 to 176°C) and cooling, 38 parts of diphenylmethane-4,4'-diisocyanate were added, and at 100°C The reaction was carried out until the isocyanate group disappeared to obtain a rosin-modified epoxy resin solution (I) with an epoxy equivalent of 745 and a heating residual component of 70%.

manufacture example 2

[0063] In a reaction device having a heating device, a stirrer, and a nitrogen introduction pipe, 250 parts of "JER834" (trade name, manufactured by Japan Epoch Resin Co., Ltd., a bisphenol A type epoxy resin with an epoxy equivalent of 250), tall rosin 17 parts and 56 parts of dehydrated castor oil fatty acids were heated to 160°C while stirring in a dry nitrogen atmosphere, and reacted until the acid value became 0. After adding 145 parts of "Suwazoru 1000" and cooling, put 18 parts of toluene diisocyanate and react at 100°C until the isocyanate group disappears to obtain a rosin-modified ring with an epoxy equivalent of 455 and a heating residue of 70%. Oxygen Resin Solution (II).

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com