Fuse-type load rejection device for underwater equipment and control method thereof

A technology for underwater equipment and device control, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of high cost, large explosion impact, etc., and achieve the effect of low power consumption and flexible quality of ballast heavy objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

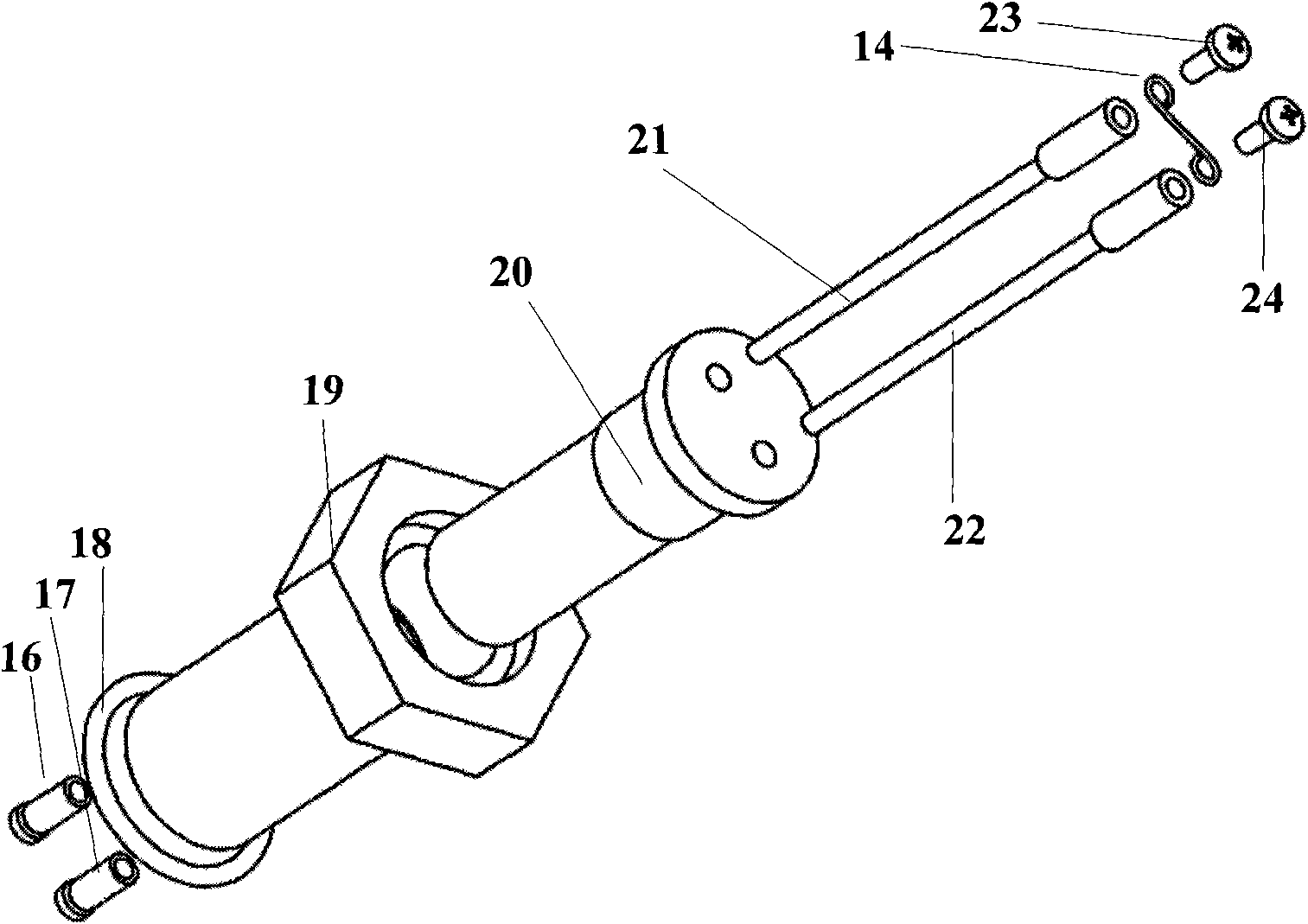

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

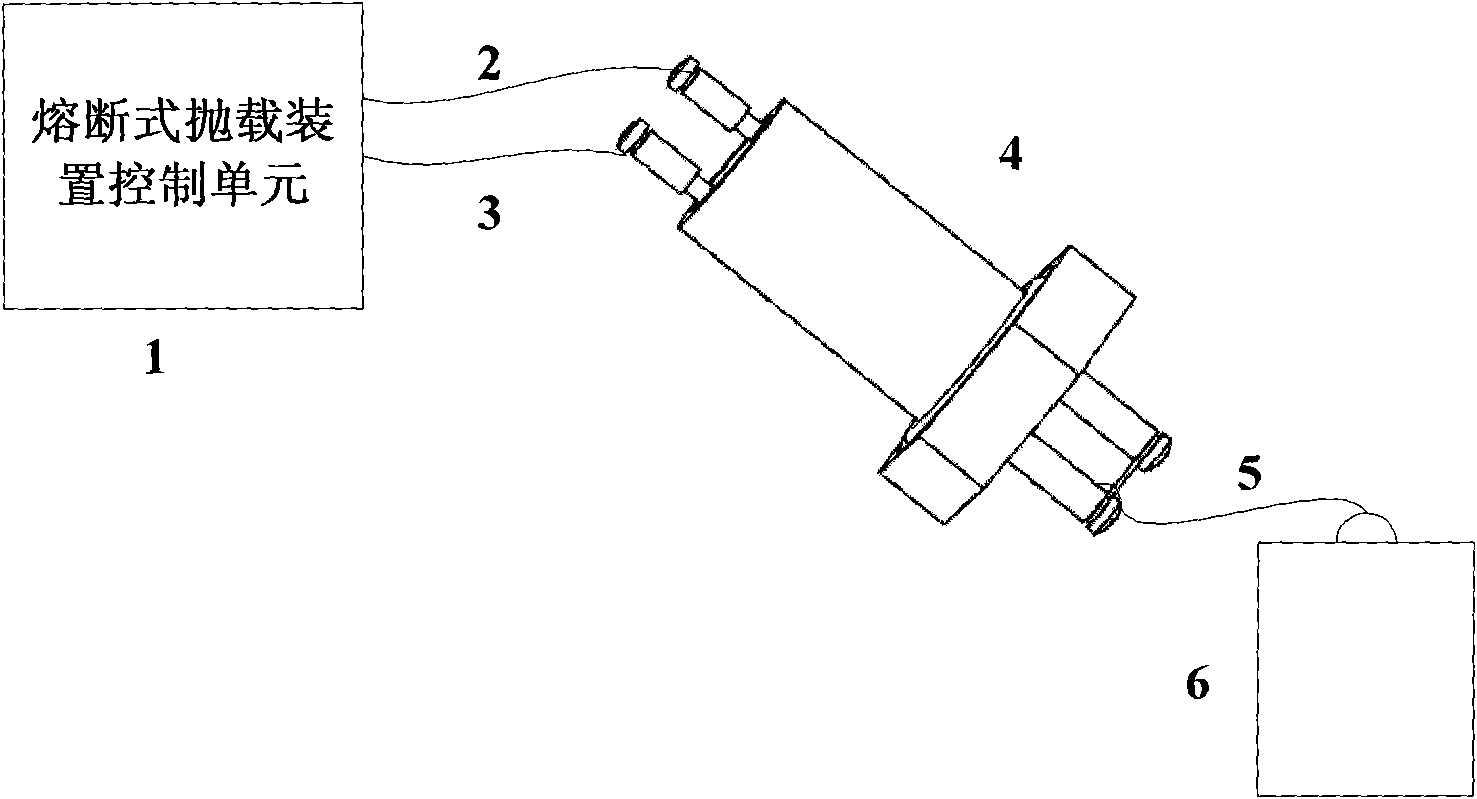

[0033] Such as figure 1 As shown, this embodiment takes an underwater robot as an example, including: a control unit 1 of a fuse-type load dumping device and a sealing connector 4 of the load dumping device, both of which are electrically connected through wires 2 and 3 . The sealing connector 4 of the load throwing device isolates the control unit 1 of the fuse type load throwing device from the ballast weight. 5 is articulated outside the underwater robot cabin.

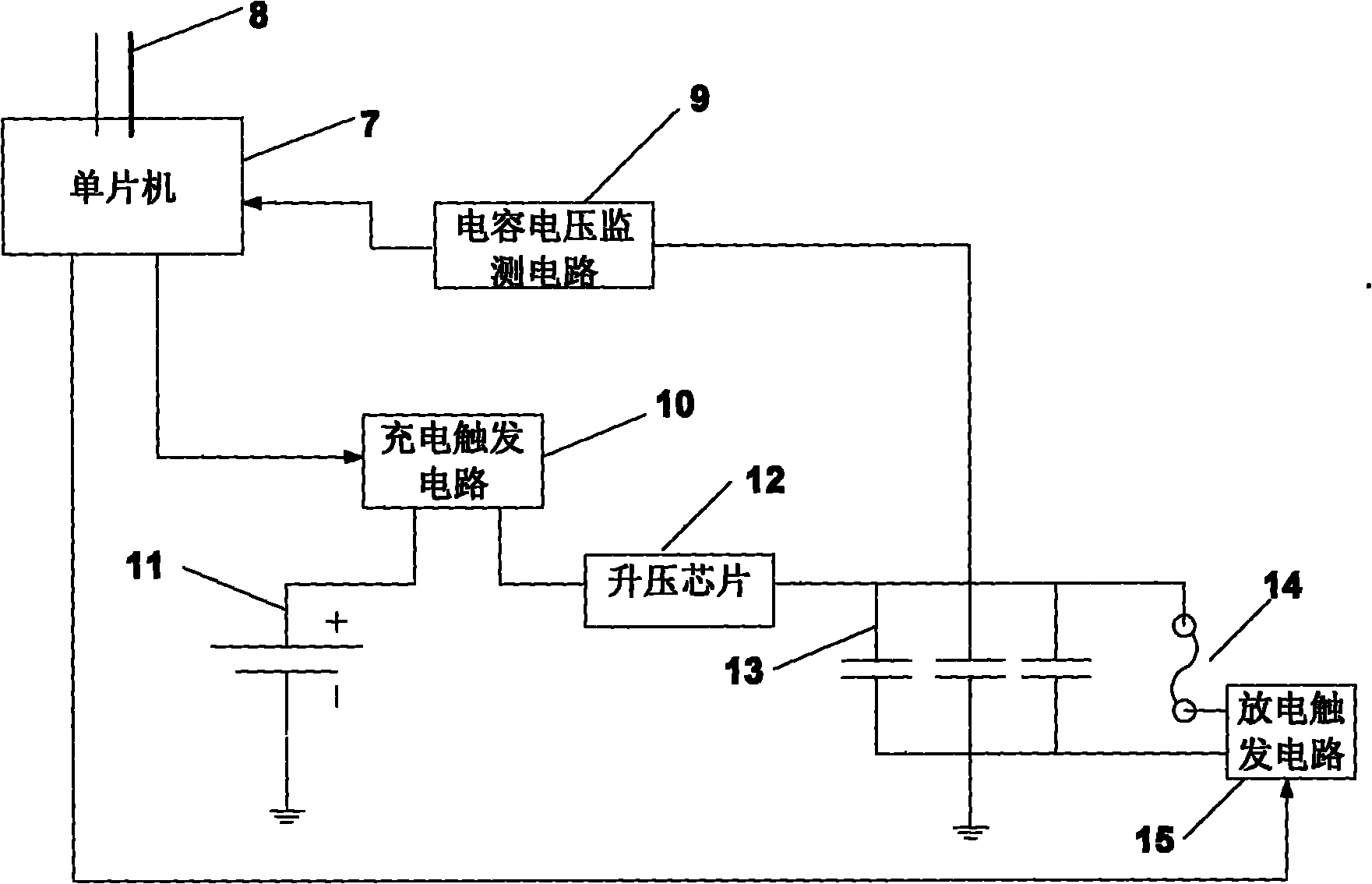

[0034] figure 2 As shown, the control unit 1 of the fuse-type load dumping device uses an ordinary AA battery 11 as a working power source. In this example, 4 cells are connected in series, and the voltage is 6V. The control unit 1 of the fuse-type load dumping device takes the single-chip microcomputer 7 as the core device, and also includes a UART serial port 8, a charging tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com