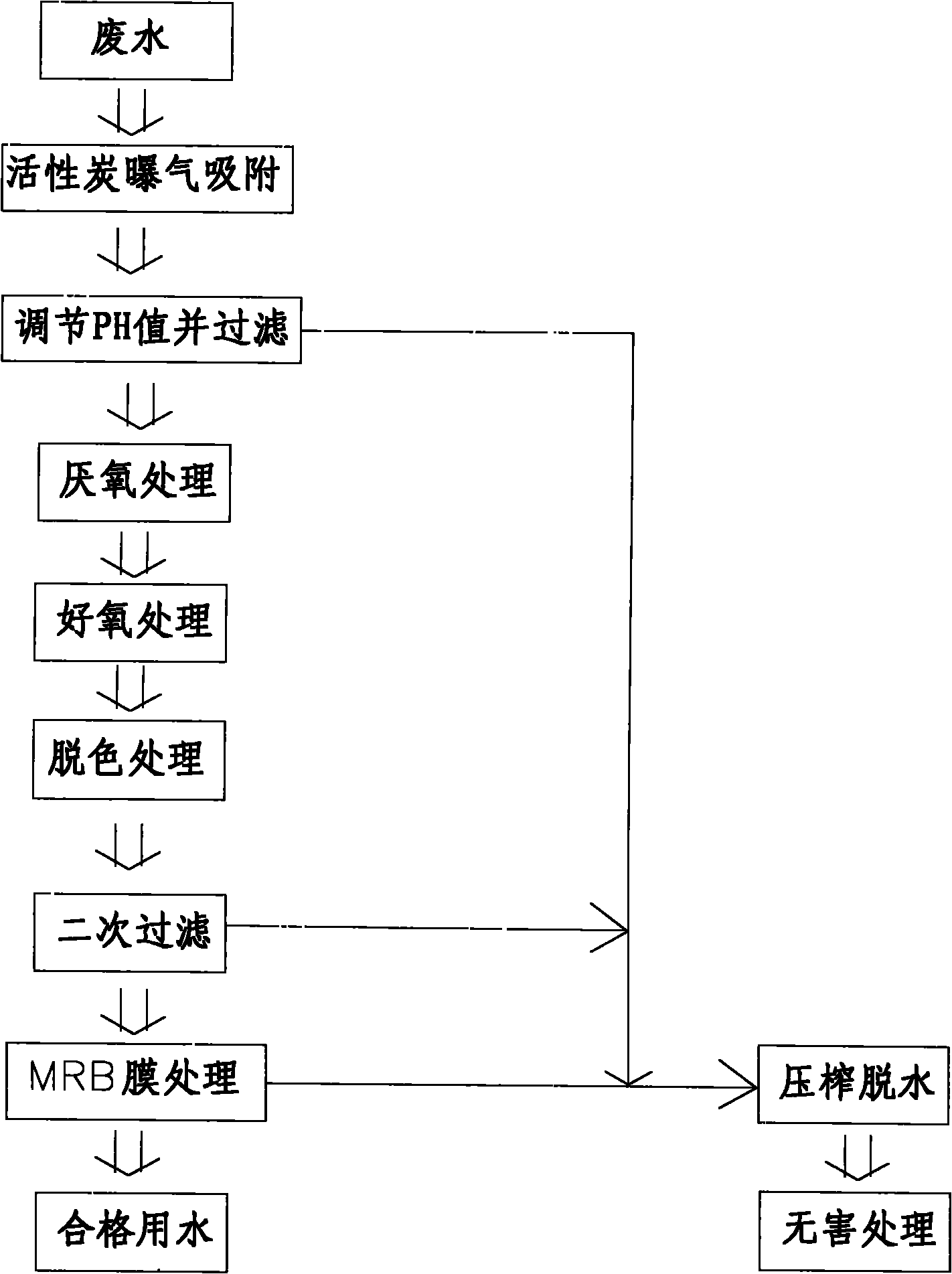

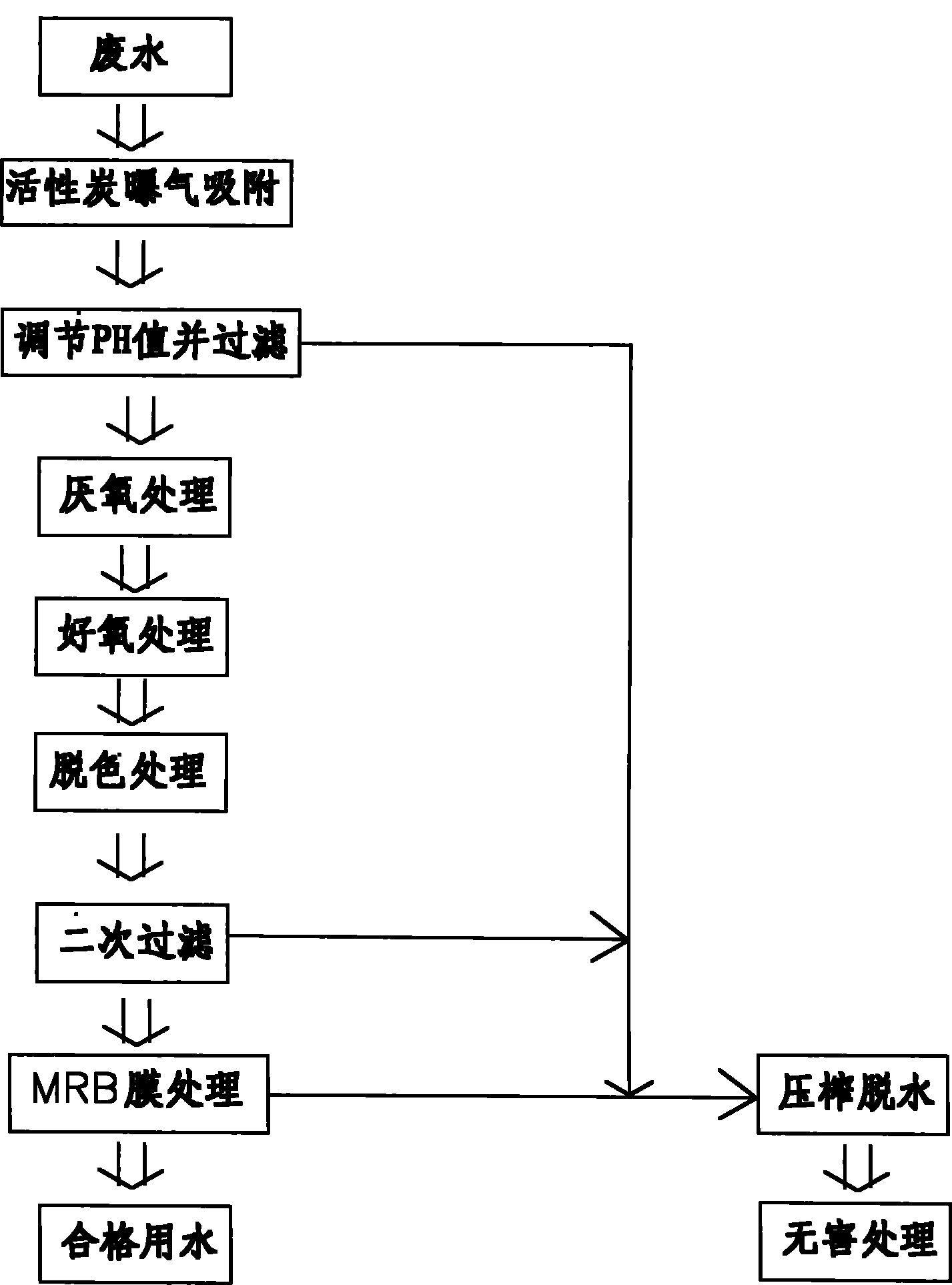

Process for treating high-concentration printing and dying waste water

A printing and dyeing wastewater and treatment process technology, applied in the printing and dyeing field, can solve the problems of high cost, large water volume, secondary pollution, etc., and achieve the effect of simple operation, high water quality and compact links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Before treatment, the pH value of the wastewater is 10, the COD is 4000, the BOD is 400, the SS suspended matter is 500, and the chromaticity is 1000.

[0023] The specific operation steps are as follows:

[0024] a. Activated carbon aeration adsorption, add activated carbon packs to the wastewater, use the bubble aeration method to oxidize and decompose the organic matter in the wastewater, and through the activated carbon adsorption, reduce the content of iron, manganese and other elements in the wastewater, so that the COD value in the wastewater will be 2000. A large number of bubbles will be generated during the aeration process, adding a defoamer with polysiloxane as the main material to stabilize the solution and provide stable conditions for subsequent processing;

[0025] b. Adjust the pH value and filter, introduce the printing and dyeing wastewater into the buffer tank, add acid and alkali solution to adjust the pH value to about 6-8, add filter aid diatomit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com