Energy-saving process for rectifying alcohol by adopting heat integration of three rectifying columns

A process method and thermal integration technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high operating energy consumption, inability to meet the standard of high-quality products, and difficult to achieve high-quality products for alcohol products. , to achieve the effect of reducing operating energy consumption, significant practicability and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

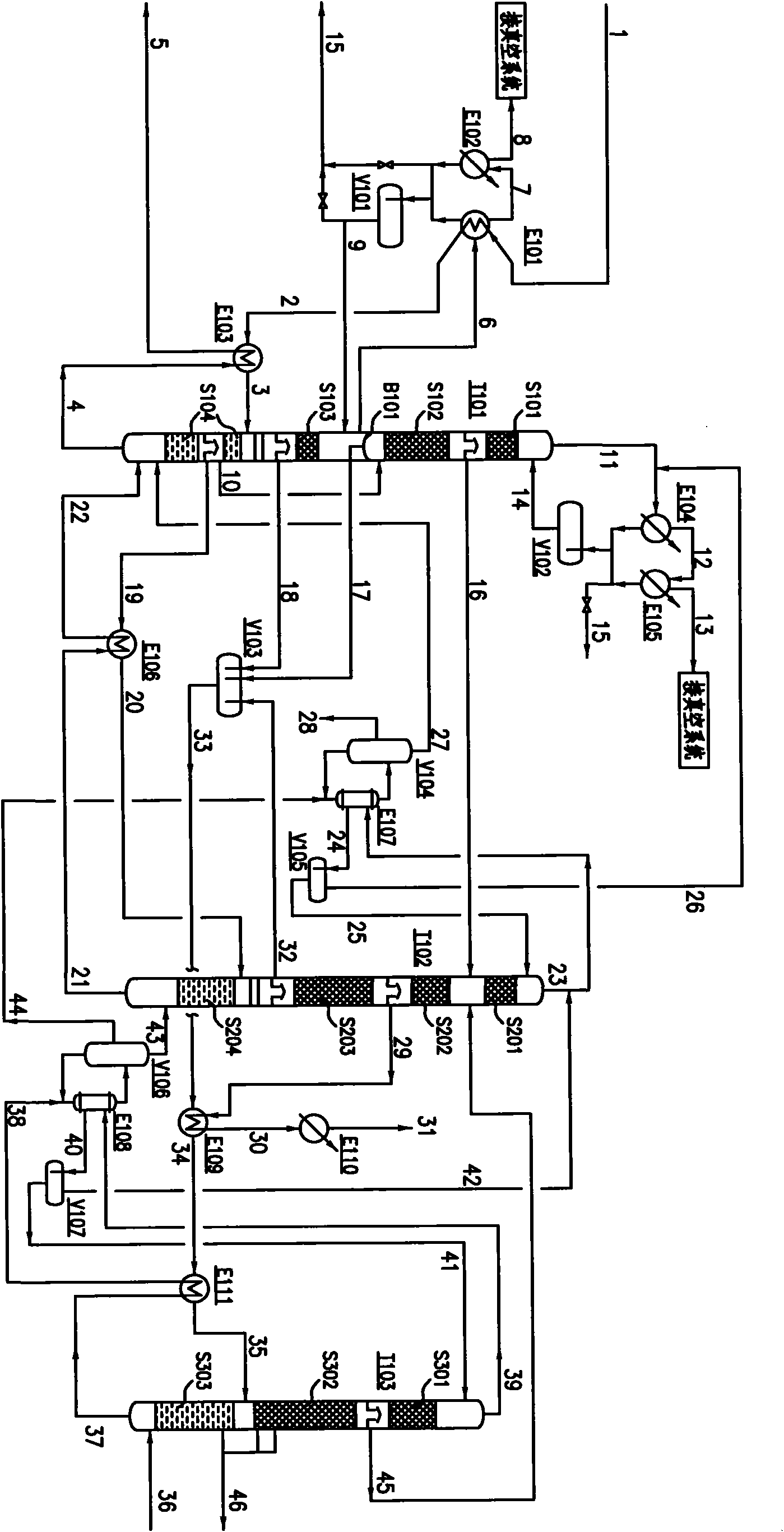

[0054] figure 1 It is a typical energy-saving process flow chart of three-refining tower heat integrated alcohol rectification.

[0055] One tower is the first rectification tower T101, the second tower is the second rectification tower T102, and the third tower is the third rectification tower T103.

[0056] The fermented mash 1 exchanges heat with the ascending gas phase 6 of the dealdehyde section S103 through E101, and the preheated mash 2 exchanges heat with the wastewater 4 discharged from the bottom of the first rectification column through E103, and the preheated mash 3 enters the lower part of T101 Section S104, after heat exchange and cooling, the waste water containing mash is 5 out of the device.

[0057] In section S104, two streams of material are extracted from the side line below the feeding position of logistics 3, gas phase side line 10 and liquid phase side line 19 . The rising gas phase inside the S104 section is divided into two parts, one part enters th...

Embodiment 2

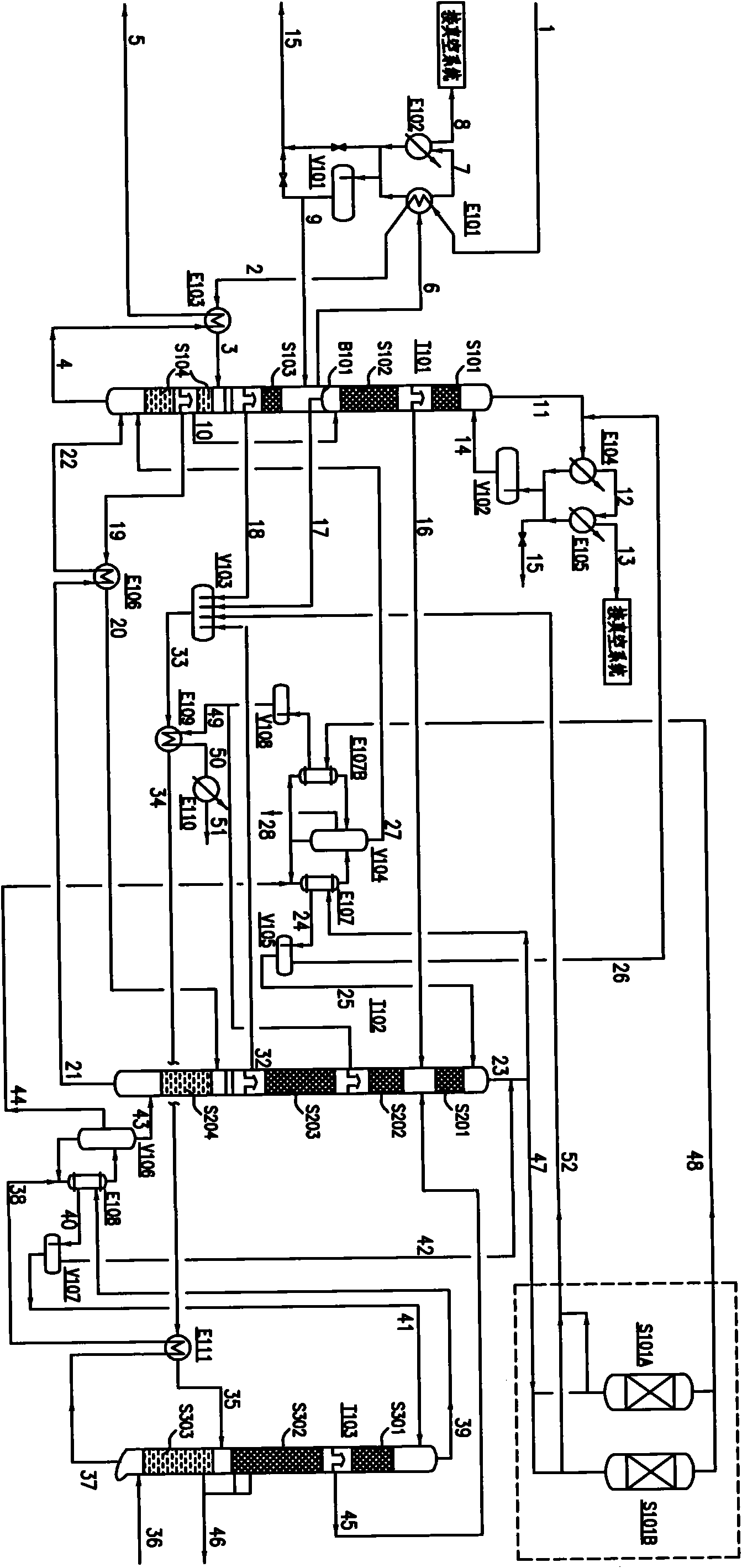

[0083] figure 2 It is a process flow chart of producing anhydrous ethanol (or fuel ethanol) by adopting the heat-integrated alcohol rectification energy-saving process method of three refined towers. figure 2 is in figure 1 On the basis of the provided process flow, a molecular sieve dehydration system and an anhydrous ethanol condenser E107B are directly added to produce anhydrous ethanol or fuel ethanol products.

[0084] A stream of azeotropic wine gas 47 is split from the top of the second rectification tower to molecular sieve dehydration towers S101A and S101B. The molecular sieve dehydration tower is divided into two switching operations, one is in adsorption dehydration, and the other is in desorption regeneration or standby state. The light wine 52 that molecular sieve desorption comes out enters light wine tank.

[0085] The azeotropic alcohol gas 47 is adsorbed and dehydrated by molecular sieves, and the absolute ethanol vapor 48 enters the absolute ethanol con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com