Catalyst with hydrogenation catalytic action, preparation method and application thereof and method of removing asphaltene by heavy oil hydrogenation

A catalyst and hydrogenation activity technology, applied in the field of hydrocarbon oil hydrogenation, can solve problems such as transfer difficulties, molding interference, secondary dust pollution, etc., achieve the effect of simple preparation process, avoid dust pollution, and reduce operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

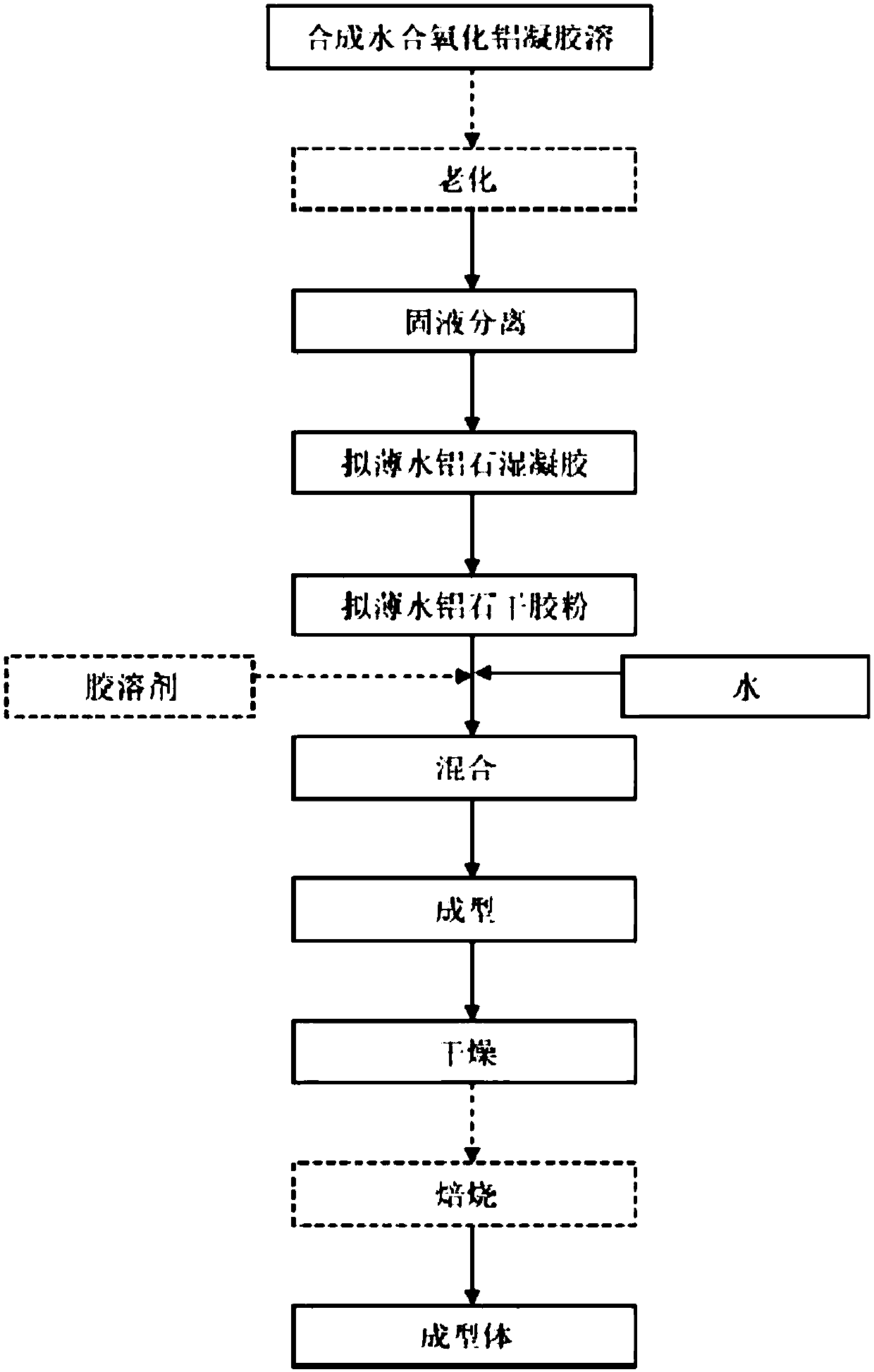

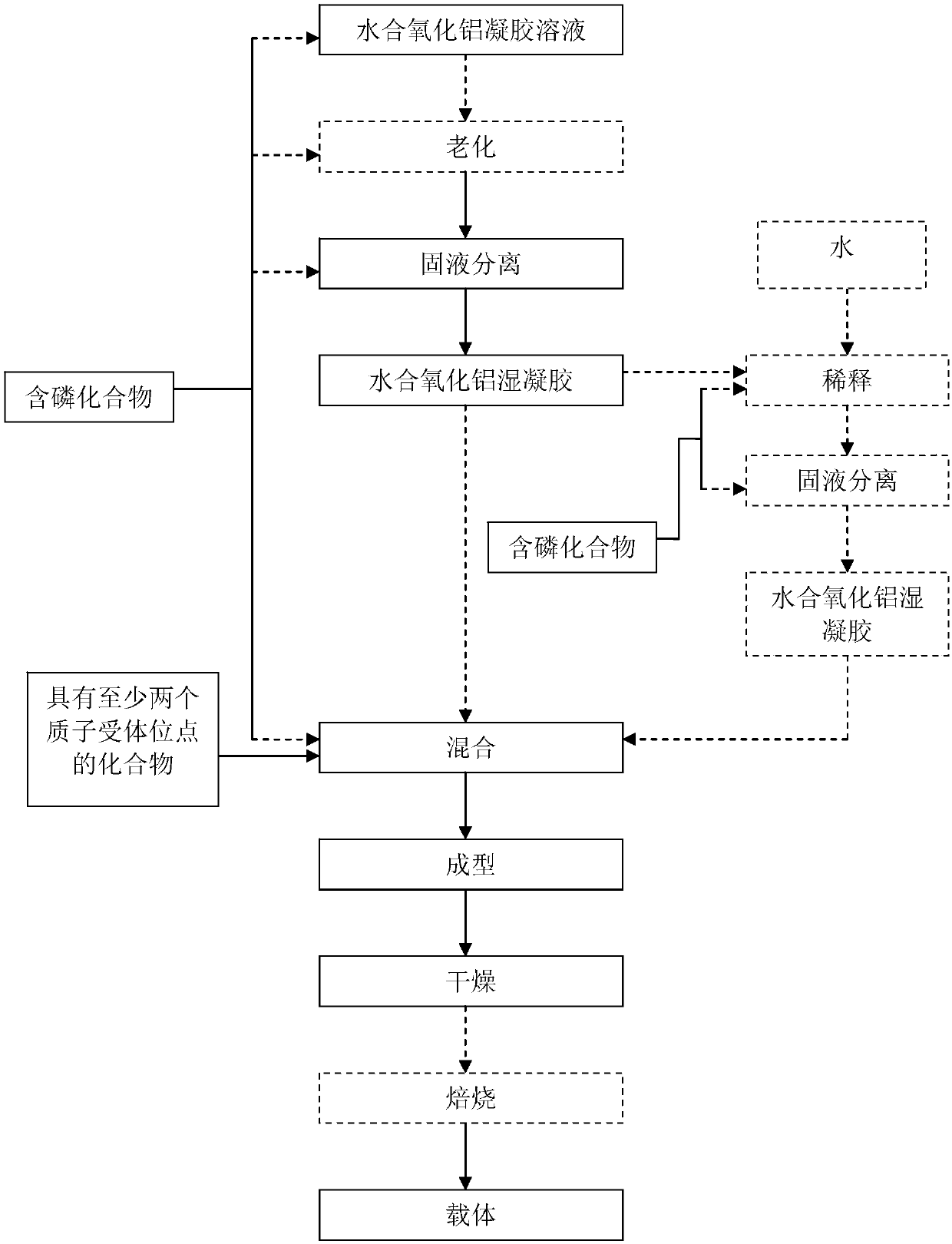

[0081] According to the preparation method of the present invention, the carrier is prepared by a method including the following steps:

[0082] (1) Mix the components in a raw material composition to obtain a hydrated alumina composition, which contains a hydrated alumina wet gel, a compound with at least two proton acceptor sites, and at least one A phosphorus-containing compound, the i value of the hydrated alumina wet gel is not less than 60%, and the amount of the compound having at least two proton acceptor sites is such that the final prepared hydrated alumina composition is Value is 1.8-5,

[0083] The i value is determined by the following method: 10g of hydrated alumina wet gel is dried at 120°C in air atmosphere for 240 minutes, and the mass of the dried sample is recorded as w 2 , Calculate the value of i using formula II,

[0084]

[0085] Said The value is determined by the following method: 10g of the composition is dried at 120°C in an air atmosphere for 240 minutes...

preparation Embodiment 1-10

[0196] Preparation examples 1-10 are used to prepare carriers.

preparation Embodiment 1

[0198] The hydrated alumina wet gel used in this preparation example is a hydrated alumina gel solution prepared by the acid method (sodium metaaluminate-aluminum sulfate method, taken from Sinopec Changling Branch) and phosphoric acid added during the aging process The phosphorus-containing pseudo-boehmite wet cake obtained by washing and filtering (the wet cake is numbered SLB-1), the i value of the wet cake is determined to be 77.7%.

[0199] (1) Put 200g of the wet filter cake numbered SLB-1 in a beaker, and then add 5g methylcellulose (purchased from Zhejiang Haishen Chemical Co., Ltd., the same below) and 3g sesame powder (galactomannan The content is 80% by weight, purchased from Beijing Chemical Reagent Company, the same below), after stirring with a mechanical stirrer for 10 minutes, the mixture obtained is the phosphorus-containing hydrated alumina composition of the present invention, and its property parameters are listed in Table 1. Out.

[0200] (2) Use the phosphoru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial crushing strength | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com