Method for preparing alpha, alpha-dimethyl benzyl alcohol by hydrogenating hydrogen dioxide isopropyl benzene

A technology for cumene hydrogen peroxide and dimethylbenzyl alcohol, which is applied in the field of hydrogen peroxide cumene hydrogenation to produce α,α-dimethylbenzyl alcohol, and can solve problems such as poor stability of Pd catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

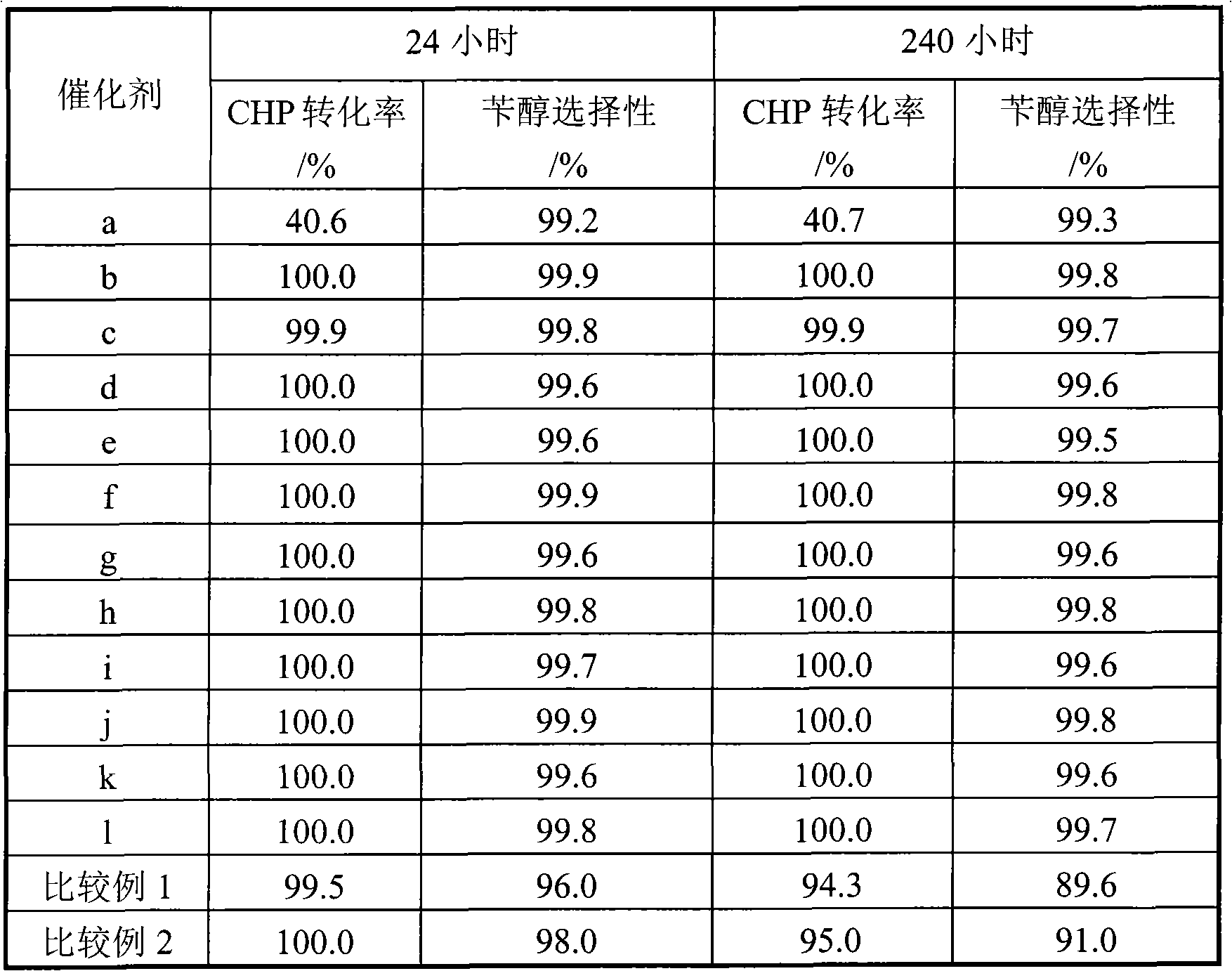

Examples

Embodiment 1

[0012] Formed Al 2 o 3 After drying at 120°C for 6 hours and calcining at 600°C for 4 hours to obtain a carrier (specific surface is 208m 2 / g, the pore volume is 0.78mL / g, and the average pore diameter is 12.5nm). The carrier is impregnated with the mixed salt solution containing the required amount of Pb, Na and Pd components, dried at 120°C for 4 hours and calcined at 550°C for 4 hours to obtain a weight percentage of 0.1%Pd-0.1%Pb-0.1%Na / Al 2 o 3 Catalyst a.

Embodiment 2

[0014] Formed Al 2 o 3 After drying at 120°C for 6 hours and calcining at 750°C for 4 hours to obtain a carrier (specific surface is 200m 2 / g, the pore volume is 0.69mL / g, and the average pore diameter is 13.2nm). Impregnate the carrier with the mixed salt solution containing the required amount of Pd, Sn and In components and dry at 120°C for 4 hours, then impregnate the carrier with the mixed solution containing the required amount of K and Mg components, and dry at 120°C for 4 hours Hours and 550 ° C for 4 hours to produce 0.5% Pd-2.0% Sn-1.0% In-0.5% K-1.5% Mg / SiO in terms of weight percentage 2 Catalyst b.

Embodiment 3

[0016] Al after molding 2 o 3 After drying at 120°C for 6 hours and calcining at 1200°C for 2 hours to obtain a carrier (specific surface is 75m 2 / g, the pore volume is 0.28mL / g, and the average pore diameter is 24.6nm). The carrier is impregnated with the solution containing the required amount of Mg component, dried at 120°C for 4 hours, then impregnated with the mixed solution containing the required amount of Pd and Pb, dried at 120°C for 4 hours and calcined at 550°C for 4 hours. 0.5%Pd-1.0%Pb-10.0%Mg / Al by weight 2 o 3 Catalyst c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com