Surface material with protein adsorption resistant property and preparation method thereof

A technology of anti-protein adsorption and surface materials, which is applied in the field of surface materials and its preparation, to achieve the effects of broad application prospects, reliable principles, and low reaction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

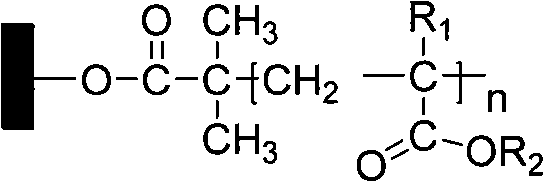

[0011] Example 1: Preparation of surface materials with anti-protein adsorption properties

[0012] (1) In a 250mL round bottom flask, add 2mmol triethylamine, 200mL tetrahydrofuran as solvent, add surface hydroxylated silicone matrix (surface area 1cm 2 , if the surface area increases, then increase the amount of each component in the experiment according to the corresponding proportion), seal the round bottom flask, place it in an ice-water bath, add an appropriate amount of 2-bromoisobutyryl bromide after stirring for 5 minutes, and seal the round bottom flask After 5 minutes, the round-bottomed flask was taken out from the ice-water bath, and the reaction was continuously stirred for 16 hours. After the reaction, the product was taken out from the glove box, washed with methanol and deionized water successively, and rinsed with N 2 Blow dry to obtain an intermediate containing an initiating group;

[0013] (2) The following reaction process is carried out in a glove box. ...

Embodiment 2

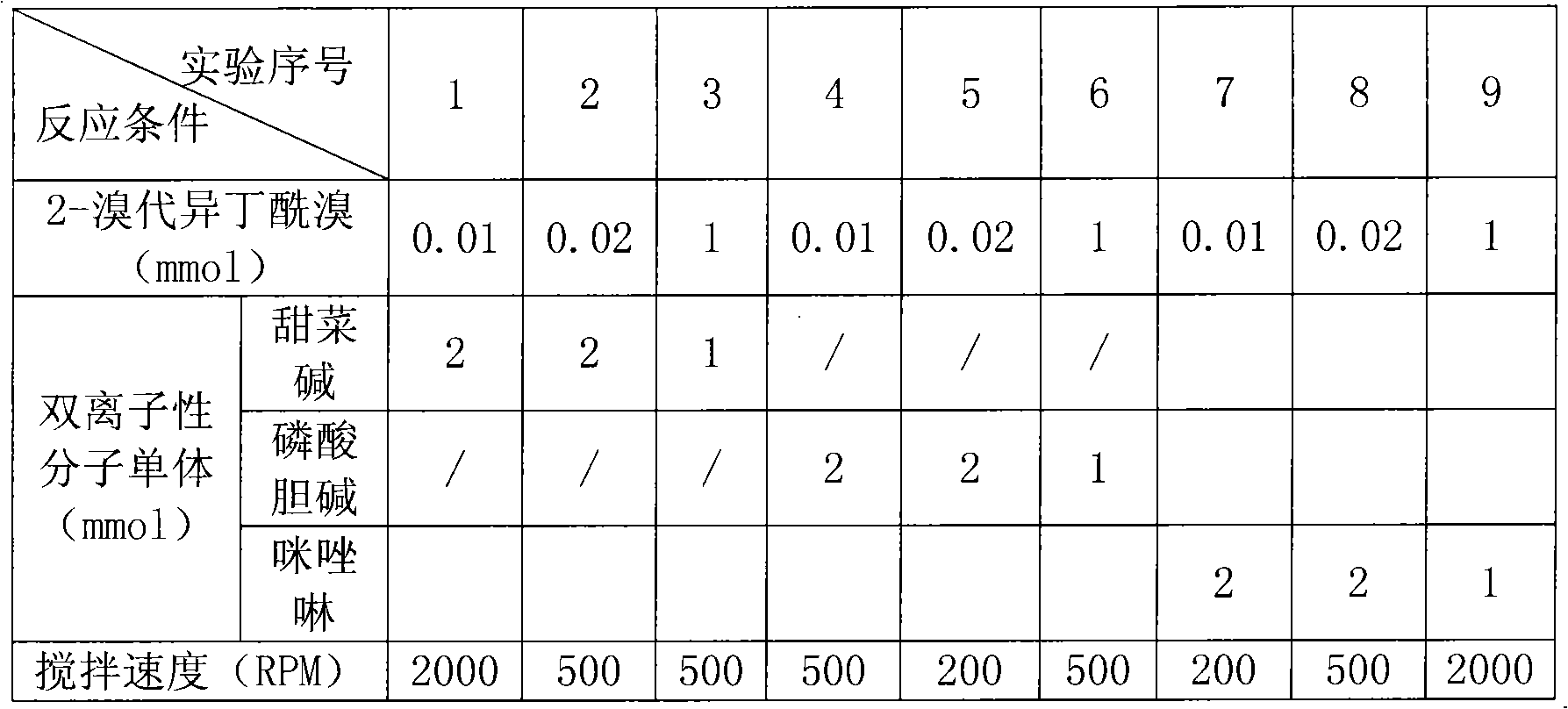

[0016] Example 2: Evaluation of anti-protein adsorption effect

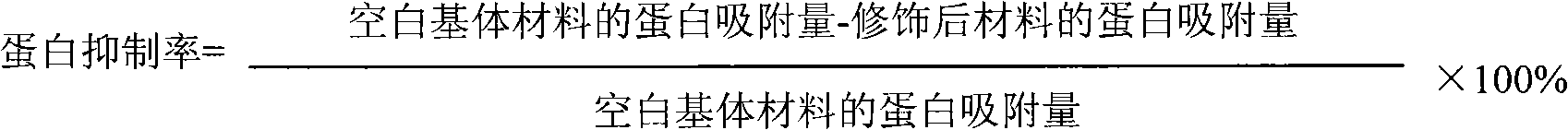

[0017] Select bovine serum albumin (Mw=6KD) as the model protein to evaluate the anti-protein adsorption performance; Soak the No. 2 organic silicon surface material prepared in Example 1 in the bovine serum albumin phosphate buffer solution of 5mL 1g / L, under normal temperature After standing for 8 hours, the sample was taken out, rinsed with phosphate buffer solution, stained with Coomassie brilliant blue for 10 minutes, and tested for protein adsorption with a UV spectrophotometer. The number of moles of adsorbed protein is the amount of protein adsorption, and the protein adsorption inhibition rate is calculated according to the difference in the amount of protein adsorption on the surface of the material before and after modification, and the expression is as follows:

[0018]

[0019] Compared with the unmodified blank organosilicon base material, the adsorption inhibition rate of the surface zwitterion-...

Embodiment 3

[0020] Embodiment 3: Antifouling effect evaluation

[0021] The organosilicon material prepared in Example 1 was subjected to a comparative test of diatom adhesion inhibition in the laboratory, and Navicula smallis was selected as the experimental algae, and the organosilicon material was immersed in an initial concentration of 1×10 5 Each / mL navicula solution was cultured at 25°C for 7 days; the attachment amount of navicula was observed and counted under a three-dimensional video microscope (observing 10 visual fields to calculate the average number). The inhibition rate of diatom attachment was calculated according to the change of the attachment amount of Navicula microalgae on the surface of the material before and after adsorption, and the formula was as follows:

[0022]

[0023]The results of the diatom inhibition test show that the zwitterionic molecule-modified organosilicon surface material can increase the inhibition rate of diatoms by 75% compared with the orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com