Novel heterogeneous moisture evaporation inhibitor preparation method

An evaporation inhibitor and heterogeneous technology, which is applied in the field of preparation of a new type of heterogeneous water evaporation inhibitor, can solve the problem that the influence of environmental factors on the specific resistance of evaporation cannot be well explained, and the inhibition of the heterogeneous liquid film system cannot be explained well. Water evaporation, lack of objective evaluation of the interaction of environmental impact factors, etc., to achieve significant economic and social benefits, good promotion prospects, and the effect of solving water shortage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

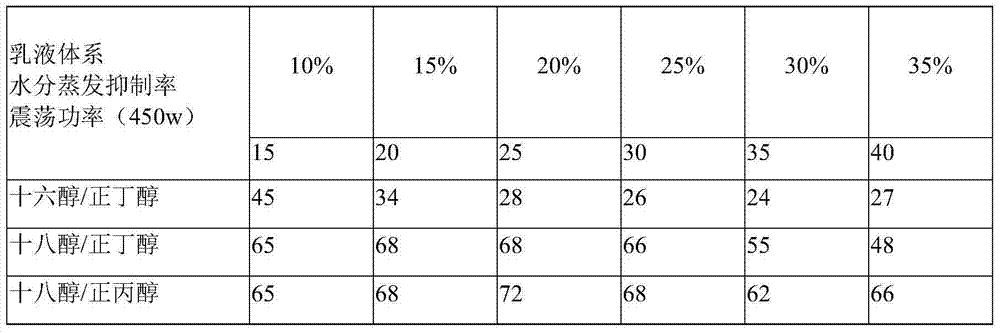

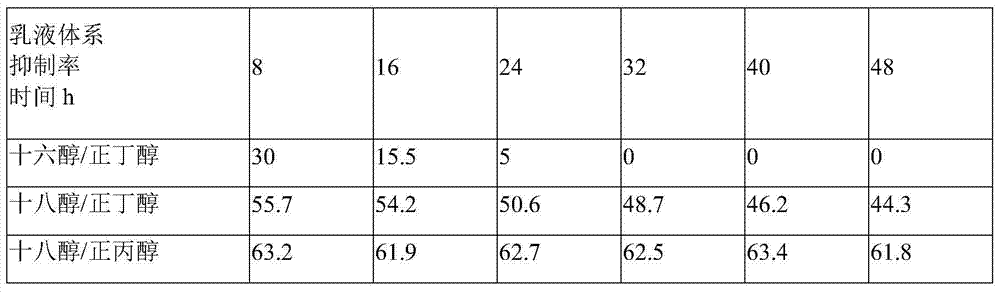

[0013] Embodiment 1. The novel heterogeneous moisture evaporation inhibitor is composed of the following components: 0.3 grams of stearyl alcohol, 1.2 grams of n-propanol, 15 grams of petroleum ether, and 0.1 grams of fatty alcohol polyoxyethylene ether series emulsifier AEO-3 and AEO-5 0.1 gram and AEO-7 0.1 gram, the balance is distilled water; Short-chain alcohol, fully dissolved in petroleum ether at room temperature, then add fatty alcohol polyoxyethylene ether series emulsifier, mix well, as a water evaporation inhibitor oil phase system; (2) Then, weigh distilled water, add the above steps In the oil phase system, put the oil phase system into the ultrasonic processor for intermittent oscillation, each oscillation is 30 seconds, the interval between two oscillations is 10-15 seconds, the oscillation power is 45-180w, and the duration: 10-20 A stable water-in-oil type heterogeneous water evaporation inhibitor can be prepared in minutes.

[0014] Experimental verificatio...

Embodiment 2

[0015] Example 2, the new heterogeneous water evaporation inhibitor is composed of the following components: 0.3 grams of stearyl alcohol, 1.3 grams of n-propanol, 15 grams of petroleum ether, fatty alcohol polyoxyethylene ether series emulsifier AEO-3 0.15 grams And AEO-5 0.15 gram, surplus is distilled water; Preparation method is the same as embodiment 1.

[0016] Experimental verification: take six exactly the same watch glass, the surface area of the watch glass is 314cm 2 About 200 grams of water were injected, five watch glasses were added with the same amount of inhibitor, and the other watch glass was not added. After standing at room temperature for 24 hours, the water evaporation of the six watch glasses were weighed and calculated, and the spread was calculated. The water evaporation inhibition rate of the emulsion system. The results show that the water evaporation of the surface plate of the spreading emulsion is obviously reduced, and the water evaporation in...

Embodiment 3

[0017] Example 3, the new heterogeneous water evaporation inhibitor is composed of the following components: 0.3 grams of stearyl alcohol, 1.5 grams of n-propanol, 15 grams of petroleum ether, fatty alcohol polyoxyethylene ether series emulsifier AEO-3 0.1 grams And AEO-5 0.1 gram and AEO-7 0.1 gram, surplus is distilled water; Preparation method is the same as embodiment 1.

[0018] Experimental verification: take six exactly the same watch glass, the surface area of the watch glass is 314cm 2 About 200 grams of water were injected, five watch glasses were added with the same amount of inhibitor, and the other watch glass was not added. After standing at room temperature for 24 hours, the water evaporation of the six watch glasses were weighed and calculated, and the spread was calculated. The water evaporation inhibition rate of the emulsion system. The results show that the water evaporation of the surface plate of the spread emulsion is obviously reduced, and the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com