Method for cracking vegetable oil through oil-water mixing mode based on high voltage pulse device

An oil-water mixing, high-pressure pulse technology, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, biological raw materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

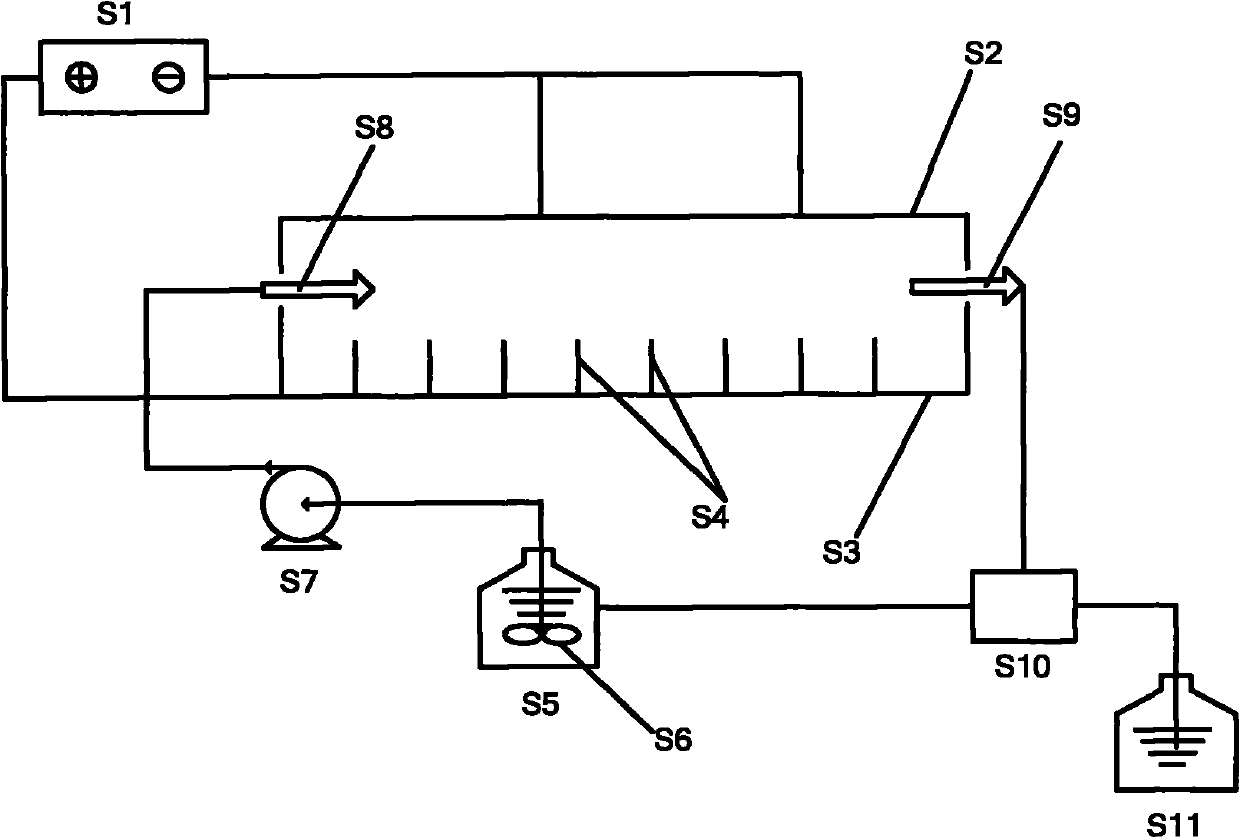

Embodiment 1

[0018] First put 1L of rapeseed oil into the oil reservoir S5, and put 1L of pure water into the oil reservoir S5 according to the volume ratio of 1:1, start the stirrer S6, start to stir the oil and water, about 5-7 Within minutes, the oil and water are fully mixed; then pump S7 is started, and the fully stirred oil and water mixture is transported into the reaction vessel through the inlet pipe S8 under the force of the pump. The flow rate of the oil and water mixture is 0.1 L / sec; positive electrode According to the density on the board 1 piece / cm 2 Arrange needle-shaped electrodes, the field strength between the positive electrode plate and the negative electrode plate is 10kv / cm, the discharge frequency is 50hz, and the pulse width is 5μs; start the high-voltage pulse power supply S1, the pulse power supply starts to discharge, and the oil-water mixture flows through the reaction vessel Under the action of high-voltage pulse, the needle electrode continuously discharges, an...

Embodiment 2

[0020] First put 2L of tung oil into the oil reservoir S5, and put 10L of pure water into the oil reservoir S5 according to the volume ratio of 1:5, start the agitator S6, start to stir the oil and water, about 5-10 minutes Time, the oil and water are fully mixed; then the pump S7 is started, and the fully stirred oil and water mixture is transported into the reaction vessel through the inlet pipe S8 under the force of the pump, and the flow rate of the oil and water mixture is 1 liter / sec; on the positive electrode plate According to density 10 roots / cm 2 Arrange needle-shaped electrodes, the field strength between the positive electrode plate and the negative electrode plate is 100kv / cm, the discharge frequency is 500hz, and the pulse width is 10μs; start the high-voltage pulse power supply S1, the pulse power supply starts to discharge, and the oil-water mixture flows through the reaction vessel Under the action of high-voltage pulse, the needle electrode continuously dischar...

Embodiment 3

[0022] First put 5L of palm oil into the oil reservoir S5, and put 50L of pure water into the oil reservoir S5 according to the volume ratio of 1:10, start the agitator S6, start mixing the oil and water, about 7-10 minutes The oil and water are fully mixed; then, the pump S7 is started, and the fully stirred oil and water mixture is transported into the reaction vessel through the inlet pipe S8 under the force of the pump, and the flow rate of the oil and water mixture is 10 liters / sec; positive electrode According to the density of 20 pcs / cm 2 Needle-shaped electrodes are arranged, the field strength between the positive electrode plate and the negative electrode plate is 500kv / cm, the discharge frequency is 5khz, and the pulse width is 30μs; start the high-voltage pulse power supply S1, the pulse power supply starts to discharge, and the oil-water mixture flows through the reaction vessel Under the action of high-voltage pulse, the needle electrode continuously discharges, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com