Cleaning solvent and cleaning method for butyl rubber polymerization reactor

A technology for polymerization reactors and butyl rubber, which is applied to liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problems of long cleaning time, high energy and material consumption, and low effective operating rate of reactors, etc. problems, to achieve the effect of improving the cleaning effect, saving operating time, and improving the effective operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The butyl rubber polymerization reactor cleaning solvent 1 of the present invention is a mixture of C4-C10, C14, and C15 saturated hydrocarbons, wherein C6-C8 is 74%wt, and the content of C10, C14, and C15 hydrocarbons is 36%wt. Its distillation range is 120℃~170℃. Its aniline point is 65°C; bromine value is 210mg / 100g.

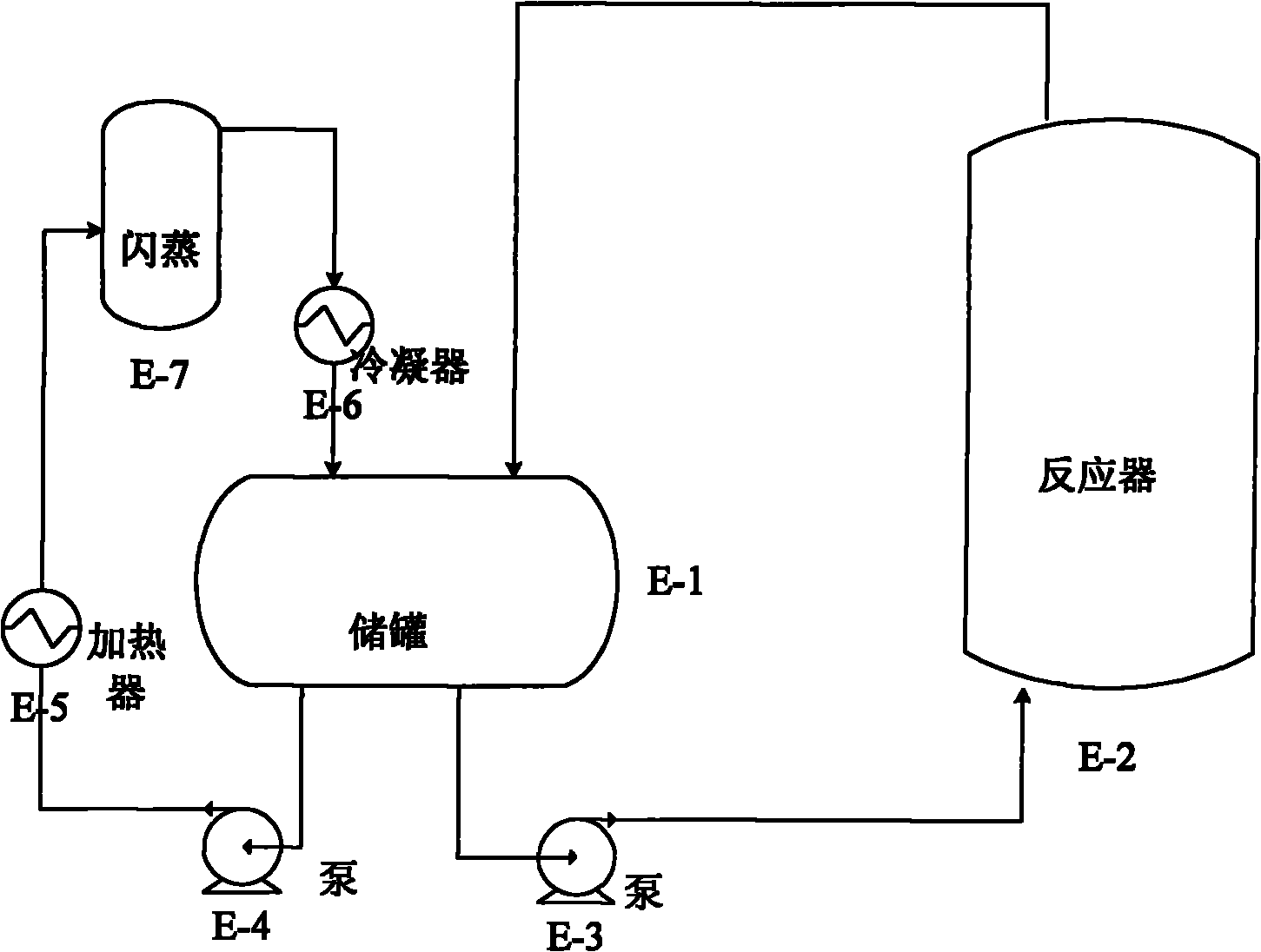

[0017] Such as figure 1 The cleaning solvent of the present invention is sent to the reactor through the pump E-3 to clean the reactor, and the solvent from the reactor is returned to the storage tank for circular cleaning. And in the cleaning process, the solvent is transported through the pump E-4 through another outlet, heated to 175°C by the heater E-5, and most of the solvent is vaporized in the flash tank, and the solvent that becomes gas phase passes through the condenser E -6 is condensed into a liquid, and then enters the storage tank for recycling. The remaining high-concentration glue in the flash tank is discharged from the bottom of the...

Embodiment 2

[0023] The butyl rubber polymerization reactor cleaning solvent 2 of the present invention is a mixture of C4-C10, C14 and C15 saturated hydrocarbons, wherein C5-C7 is 40%, and the content of C10 and C14 hydrocarbons is 60%wt. Its distillation range is 165℃~230℃. Its aniline point is 70°C; bromine value is 102mg / 100g.

[0024] The cleaning process is the same as in Example 1. The regeneration heating temperature is 190°C. The specific comparative data are shown in Table 1. Note: The original solvent in Table 1 is a mixed hydrocarbon of C4-C8, and the content of unsaturated hydrocarbon is 7%wt.

[0025] Table 1

[0026] project

Original solvent

Solvent of the present invention

The number of times to clean the reactor (times)

57

59

Average cleaning time (hours)

10.3h

5.9h

Number of regenerations (number of times)

57 a

59 b

Regeneration time (hours)

20.7

12.1

Average reduction in ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com