High-strength high-conductivity micro-boron copper alloy material and preparation method thereof

A high-conductivity, high-strength technology, applied in the fields of high-strength and high-conductivity copper alloy materials and preparation, high-strength and high-conductivity micro-boron copper alloy materials and preparation fields, can solve problems that go against sustainable development strategies and are difficult to recycle. Use, increase production costs and other issues, to achieve good industrial application prospects, easy recycling, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments.

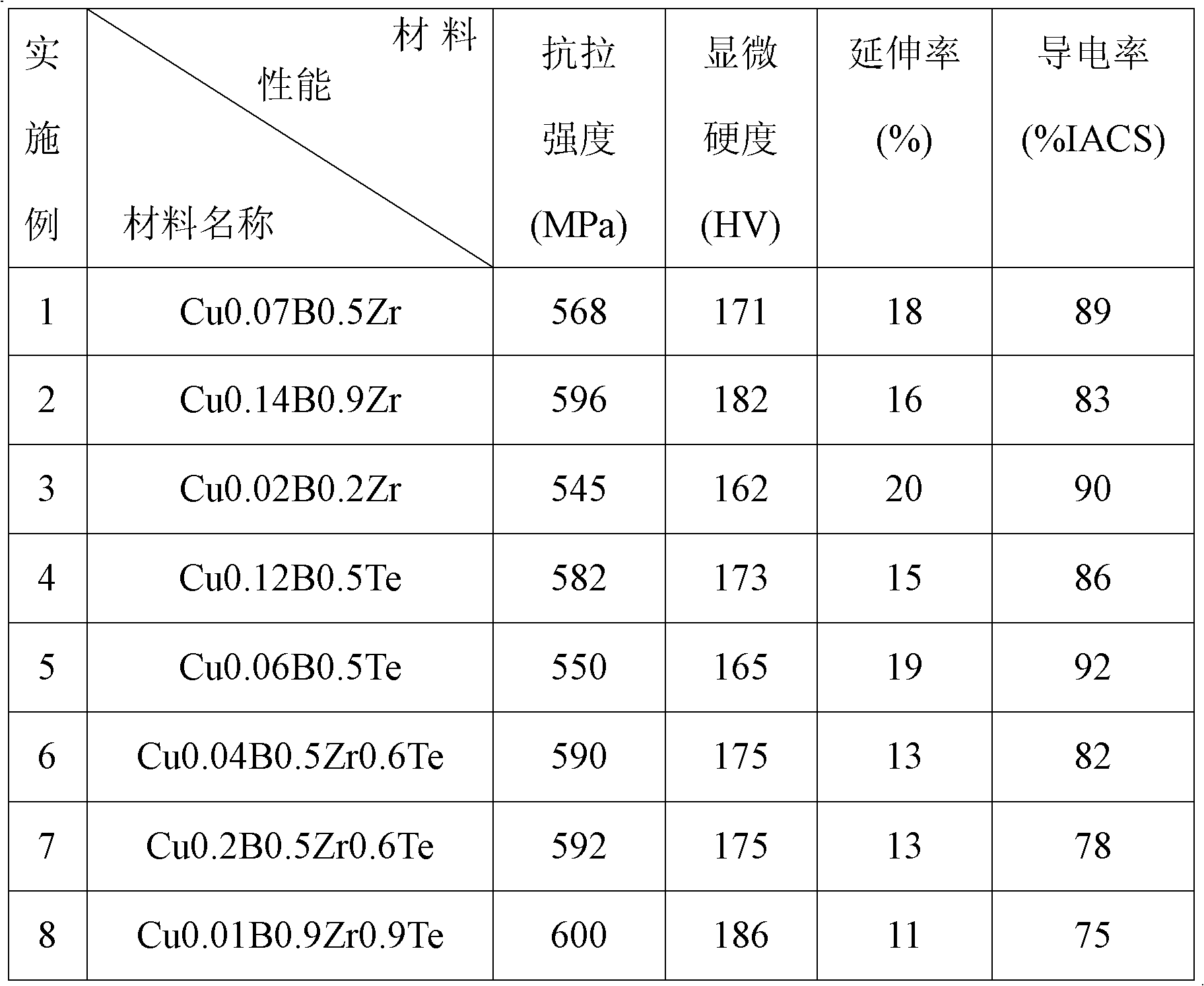

[0025] The present invention provides 8 embodiments, and the alloy components are respectively:

[0026] 1. Cu0.07B0.5Zr,

[0027] 2. Cu0.14B0.9Zr,

[0028] 3. Cu0.02B0.2Zr,

[0029] 4. Cu0.12B0.5Te,

[0030] 5. Cu0.06B0.5Te,

[0031] 6. Cu0.04B0.5Zr0.6Te

[0032] 7. Cu0.2B0.5Zr0.6Te

[0033] 8. Cu0.01B0.9Zr0.9Te

[0034] Adopt the following process method to prepare and process;

[0035] Step 1: Smelting

[0036] According to the distribution ratio of each component of the alloy, boron, rare metals and copper are weighed respectively, and melted in vacuum or in the atmosphere. The melting temperature is 1200±50°C, and the iron mold is cast into an ingot;

[0037] The second step: hot rolling after a solid solution

[0038] Heat the alloy after the first step of smelting to 900-1000°C, keep it warm for 0.5-1.5h, quench it in water, perform a solid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com