High-performance high temperature solid self-lubricating coating and preparation method thereof

A self-lubricating coating, high-temperature solid technology, used in coatings, metal material coating processes, melt spraying and other directions, can solve problems such as parts wear, reduce friction and wear, and promote development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

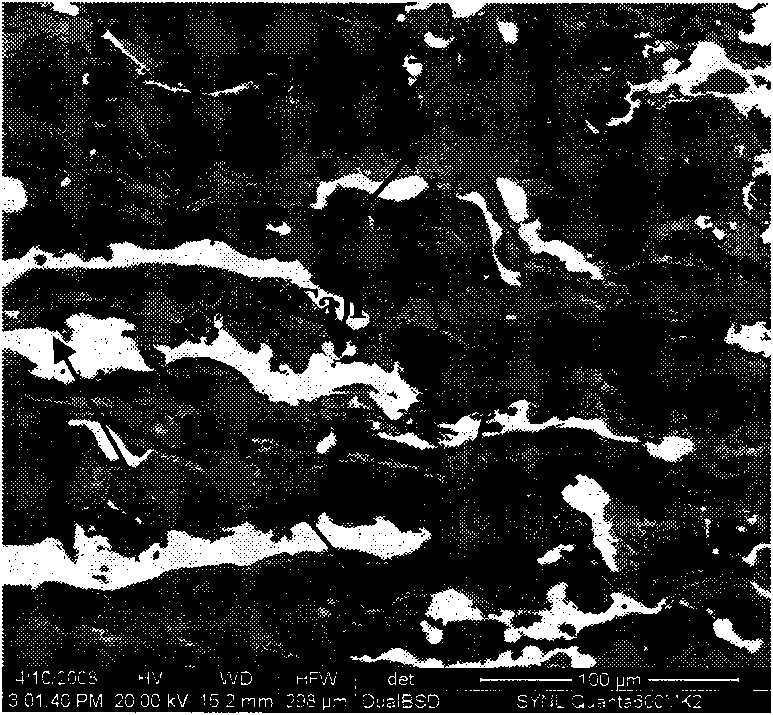

[0032] The preparation method of the high-performance high-temperature solid self-lubricating coating of the present invention, the specific steps are as follows:

[0033] Step 1: According to the proposed BaF 2 / CaF 2 The ingredients are batched and mixed uniformly, and NiCr alloy ingots are vacuum induction melted.

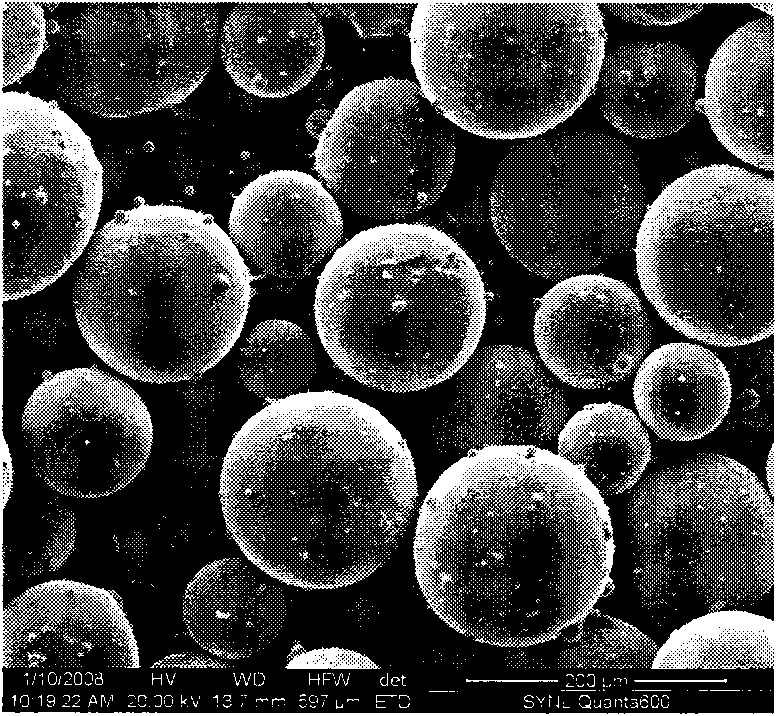

[0034] Step 2: Preparation of eutectic BaF by ultrasonic gas atomization 2 / CaF 2 powder, NiCr powder, Ag powder.

[0035] Step 3: The BaF prepared in step 2 is analyzed by scanning electron microscope 2 / CaF 2 The powder was observed for its morphology.

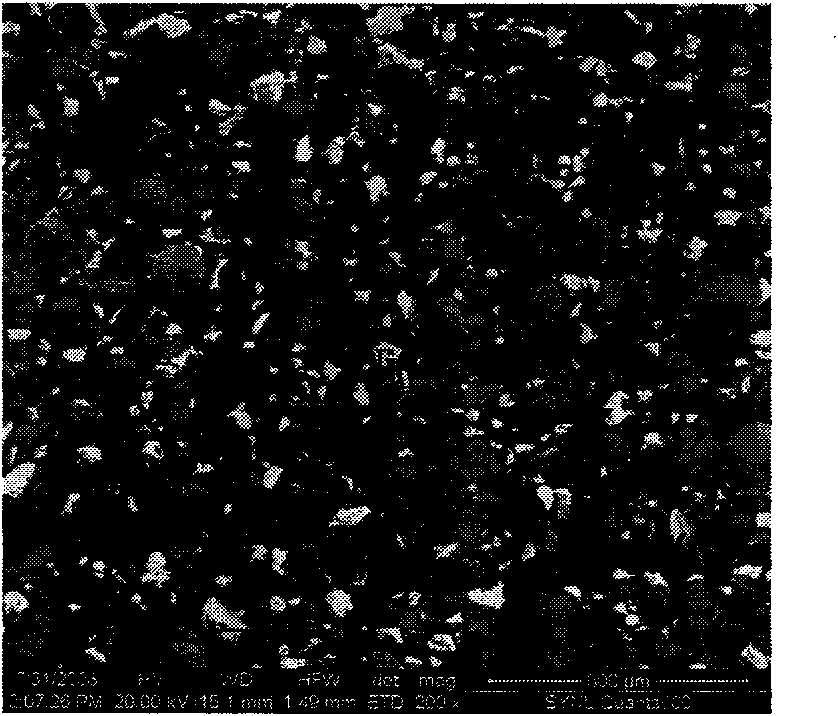

[0036] Step 4: According to the mass fraction and particle size of each component in the proposed composite powder, NiCr, Cr 2 o 3 , Ag and eutectic BaF 2 / CaF 2 The powder is mechanically mixed for 6-15 hours to obtain a high-temperature solid self-lubricating composite powder.

[0037] Step 5: Using a scanning electron microscope with an energy spectrum analyzer to observe the structure and compos...

Embodiment 1

[0045] The preparation method of the high-performance high-temperature solid self-lubricating coating in this embodiment, the specific steps are as follows:

[0046] Step 1: Press BaF 2 / CaF 2 Composition 68% BaF 2 , 32%CaF 2 Batching and mixing uniformly; vacuum induction melting NiCr alloy ingot, wherein Ni accounts for 80%, and the rest is Cr (mass fraction).

[0047] Step 2: Preparation of eutectic BaF by ultrasonic gas atomization 2 / CaF 2 powder, NiCr powder, Ag powder. Eutectic BaF 2 / CaF 2 The atomization process parameters are: atomization pressure 5MPa, atomization temperature 1350°C, vacuum degree 5Pa, melt flow rate 3kg / min. The atomization process parameters of NiCr powder are: atomization pressure 5MPa, atomization temperature 1510°C, vacuum degree 10Pa, melt flow rate 5kg / min. The atomization process parameters of the Ag powder are atomization pressure 4MPa, atomization temperature 1120°C, vacuum degree 8Pa, and melt flow rate 5kg / min.

[0048] Step 3:...

Embodiment 2

[0064] The preparation method of the high-performance high-temperature solid self-lubricating coating in this embodiment, the specific steps are as follows:

[0065] Step 1: Press BaF 2 / CaF 2 Composition 62% BaF 2 , 38%CaF 2 Batching and mixing uniformly; vacuum induction melting NiCr alloy ingot, wherein Ni accounts for 75% (mass fraction), and the rest is Cr.

[0066] Step 2: Preparation of eutectic BaF by ultrasonic gas atomization 2 / CaF 2 powder, NiCr powder, Ag powder. Eutectic BaF 2 / CaF 2 The atomization process parameters are: atomization pressure 10MPa, atomization temperature 1400°C, vacuum degree 5Pa, melt flow rate 4kg / min. The atomization process parameters of NiCr powder are: atomization pressure 7MPa, atomization temperature 1550°C, vacuum degree 8Pa, melt flow rate 6kg / min. The atomization process parameters of the Ag powder are atomization pressure 5MPa, atomization temperature 1150°C, vacuum degree 7Pa, and melt flow rate 4kg / min.

[0067] Step 3:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com