Atomizing jet-spray device for reducing agent for purifying exhaust nitric oxide of diesel engine

A technology of nitrogen oxides and injection devices, which is applied in the direction of exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problem of not being able to cover most of the cross-section of the exhaust pipe, affecting the efficiency of the SCR catalyst, and corroding the installation parts of the exhaust pipe And other problems, to achieve the effect of reducing supply accuracy, good atomization effect, reducing excess coefficient and ammonia leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

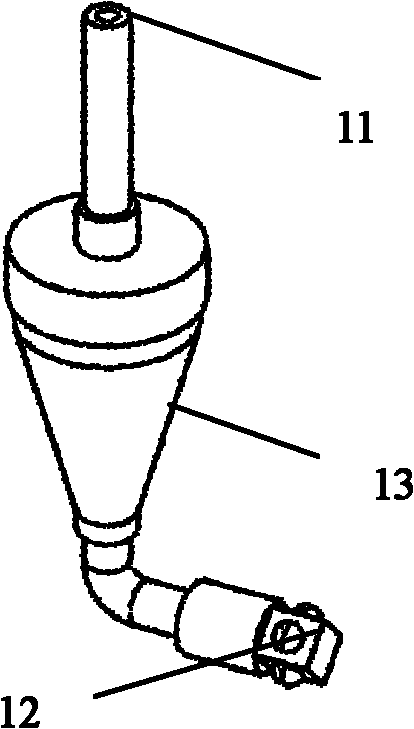

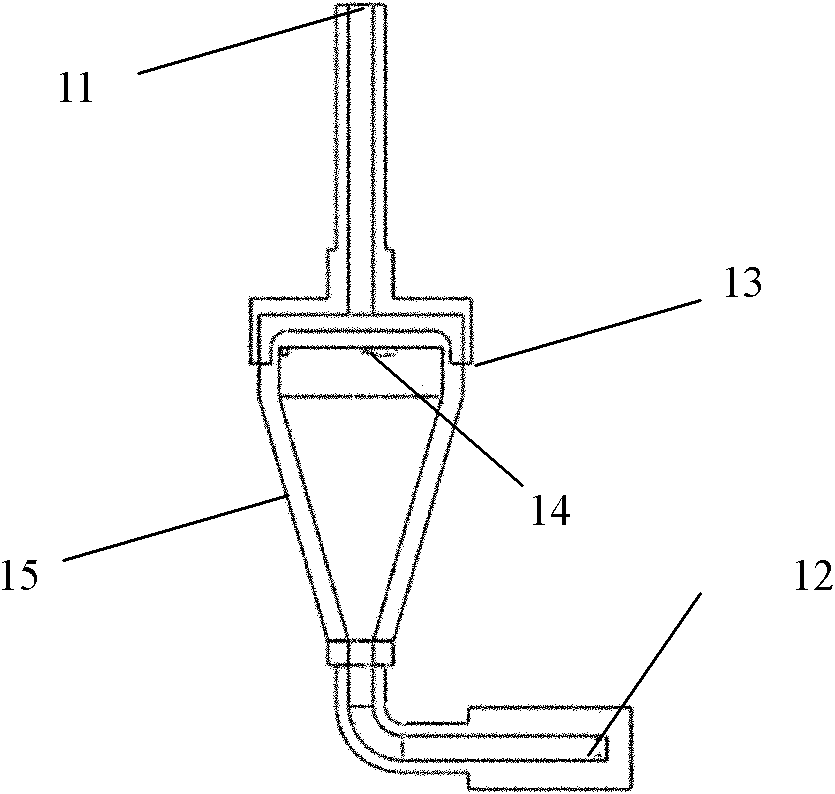

[0019] The present invention as figure 2 and image 3 As shown, the medium inlet pipe 11 communicates with the medium dispersion chamber 13, and the medium strengthening preheating chamber 15 is fixed under the medium dispersion chamber. Connected with the medium outlet pipe, four radial atomizing nozzle holes are uniformly arranged on the peripheral surface of the tail end of the medium outlet pipe 12, each nozzle hole is inlaid with a hemisphere with a groove, and the nozzle hole communicates with the groove.

[0020] The invention is made of stainless steel and installed on the exhaust pipe upstream of the SCR catalytic converter. Principle of the present invention is as follows:

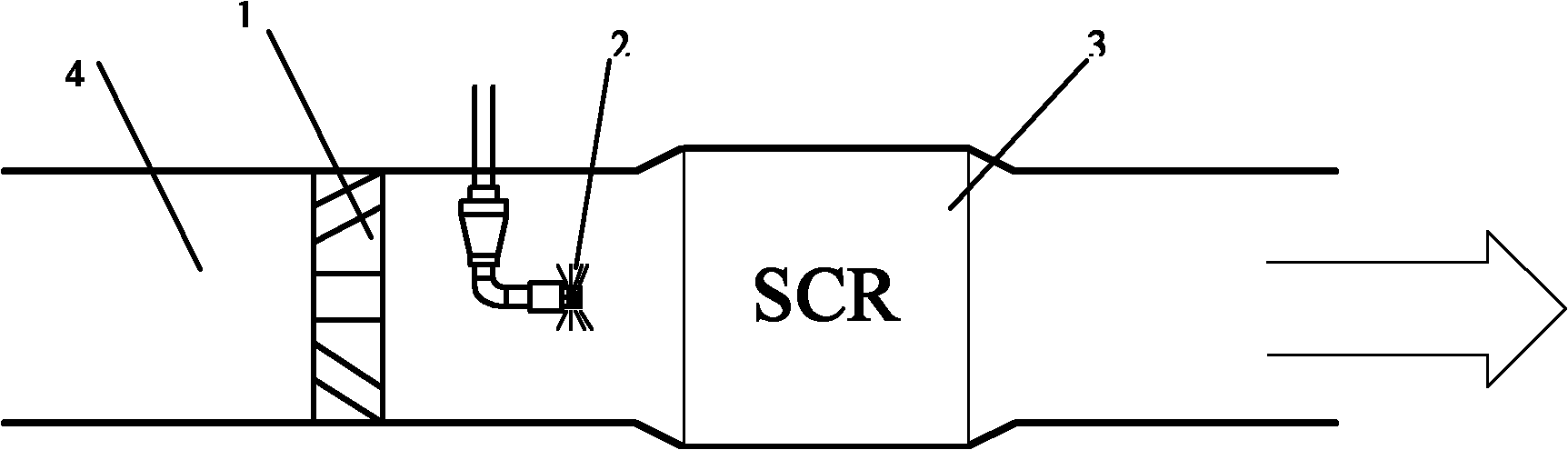

[0021] (1) heating process of the present invention (as figure 1 ): This device 2 is installed in the exhaust pipe 4, between the cyclone 1 and the SCR catalytic converter 3, the med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com