Finishing agent and member having overcoat formed from the finishing agent

A technology of surface agent and outer coating, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., to achieve the effects of improving corrosion resistance, increasing gloss, and reducing environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0141] 3. Preparation method of surface agent and method of manufacturing outer coating

[0142] (1) Preparation method of surface agent

[0143] The preparation method of the surface agent of the present invention is to directly add the above-mentioned components while stirring the liquid solvent, or add an appropriate amount of the concentrated solution described later, preferably to dissolve and mix, and there is no special limitation on the order of mixing the components.

[0144] (2) Manufacturing method of outer coating

[0145] The outer coating of the present invention is manufactured by the following method, making the surface agent of the present invention and the anti-oxidation layer arranged on the substrate, specifically, carrying out contact as a chemical protective film for a certain period of time, after that, by contacting with the surface agent, The topcoat layer of the present invention is produced by drying the anti-oxidation layer to which the surface age...

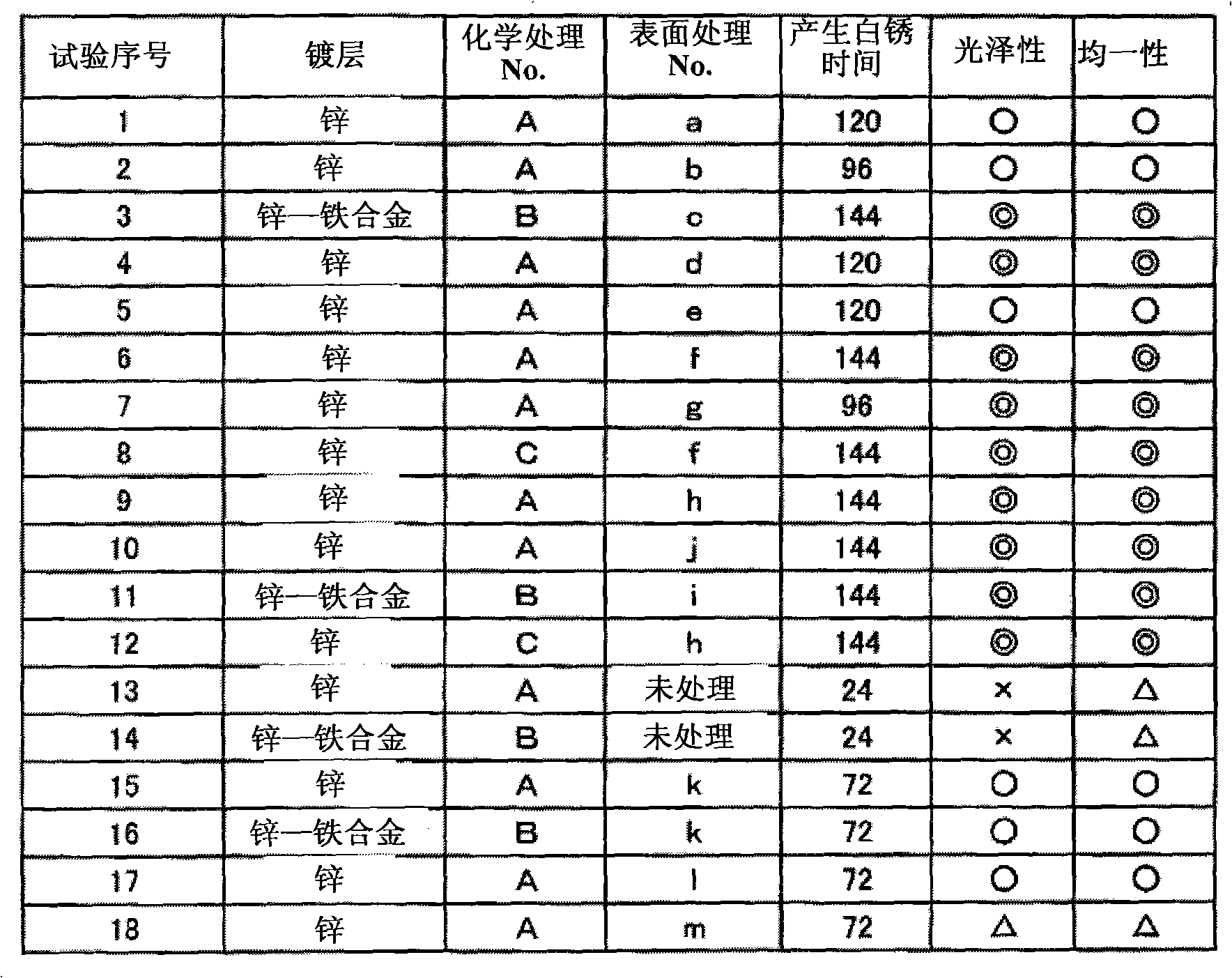

Embodiment 1

[0159] (1) Preparation of test piece

[0160] Clean the SPCC steel plate (100mm × 50mm × 0.8mm, surface area 1dm2) with known method 2 ), forming a galvanized layer or a galvanized-iron alloy layer. Regarding the respective plating layers, the following conditions apply.

[0161] Galvanizing: Galvanizing solution (METASU-ZST process of Yuken Industry Co., Ltd.)

[0162] Coating thickness 8μm

[0163] Galvanizing—iron alloy: Galvanizing solution (METASU-AZ process of Yuken Kogyo Co., Ltd.)

[0164] Iron eutectoid rate 0.4% by mass

[0165] Coating thickness 8μm

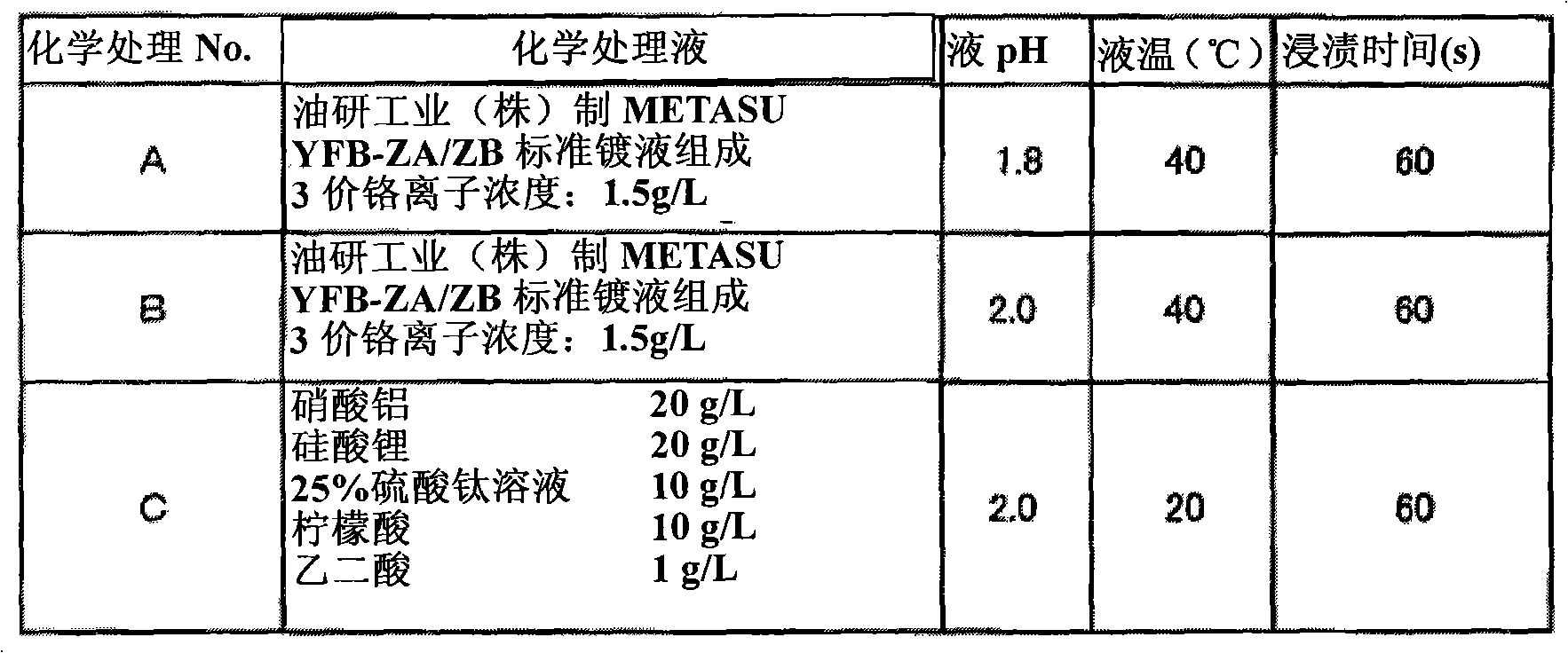

[0166] (2) chemical treatment

[0167] The steel plate that forms coating is immersed in the 67.5% nitric acid of 3ml / L under normal temperature (25 ℃) 10 seconds, carries out the activation of surface, under normal temperature (25 ℃) the steel plate after rinsing activation 10 seconds. Next, perform any one of the chemical treatments shown in Table 1 to form a chemical protection film, and wash the steel plate ...

Embodiment 2

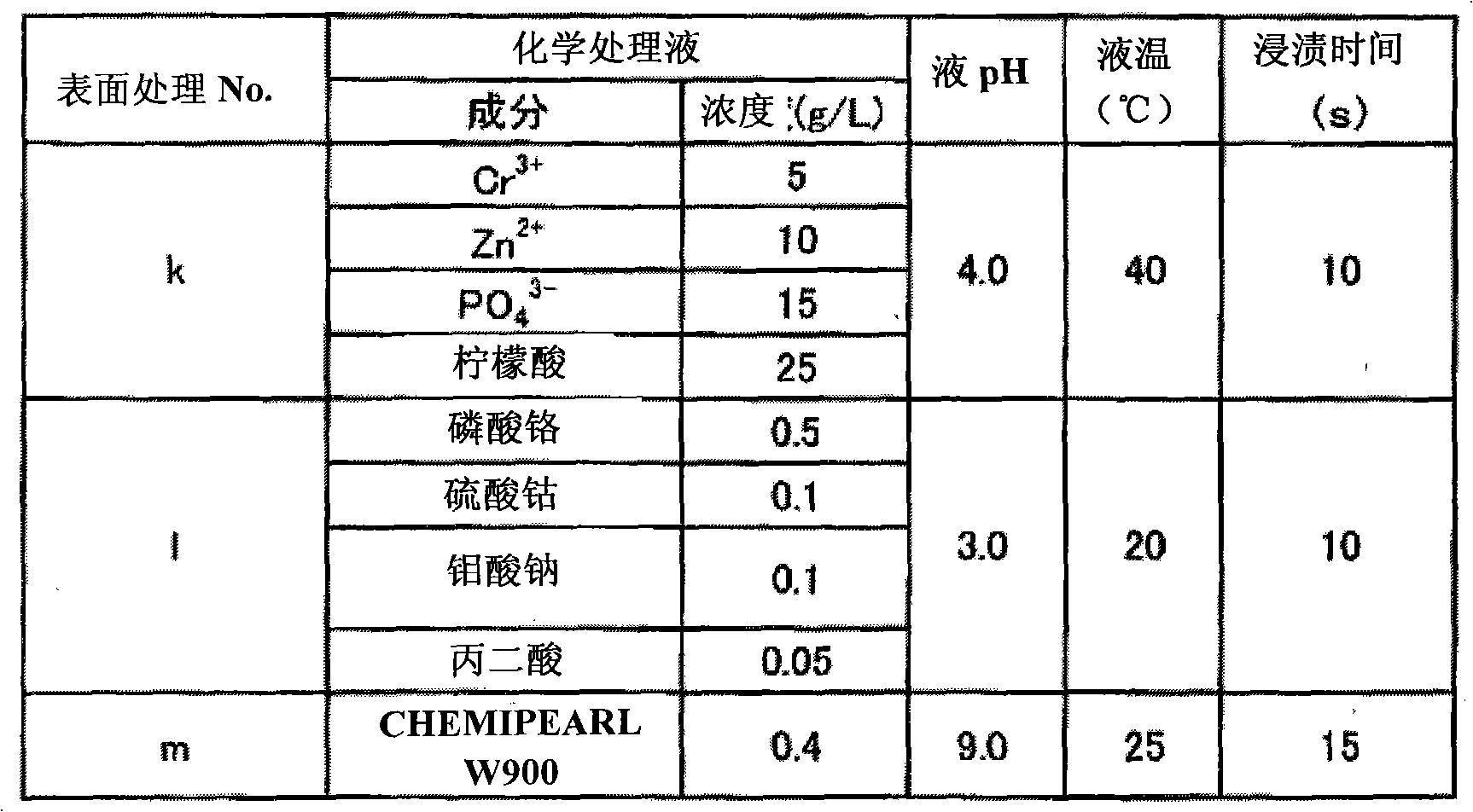

[0200] For the same test piece prepared in Example 1, the same pretreatment (activation, water washing) as in Example 1 was carried out, followed by the chemical treatment of No.C in Table 1, and the steel plate on which the chemical protective film was formed Wash with water for 10 seconds at room temperature.

[0201] Next, the surface treatment shown in Table 5 was performed on the water-washed undried steel plate after the above-mentioned chemical treatment, and the treated steel plate was treated at 80° C. for 10 minutes to prepare a test piece having an outer coating layer. In addition, a part of the steel plate was not subjected to this surface treatment, and was allowed to dry naturally to be a test piece.

[0202] [table 5]

[0203] Surface treatment No.

n

o

p

q

r

s

t

u

Al (g / L)

2

2

2

10

2

2

5

2

Zn (g / L)

12

12

12

5

5

5

20

5

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com