Plasma display panel

A plasma and display panel technology, applied in the direction of AC plasma display panels, discharge tubes, electrical components, etc., can solve problems such as difficulty in achieving low voltage effect, shortened service life of PDP, unstable chemical properties, etc., and achieve good image display performance , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0060] Next, specific examples of the PDP of the present invention will be described using the drawings.

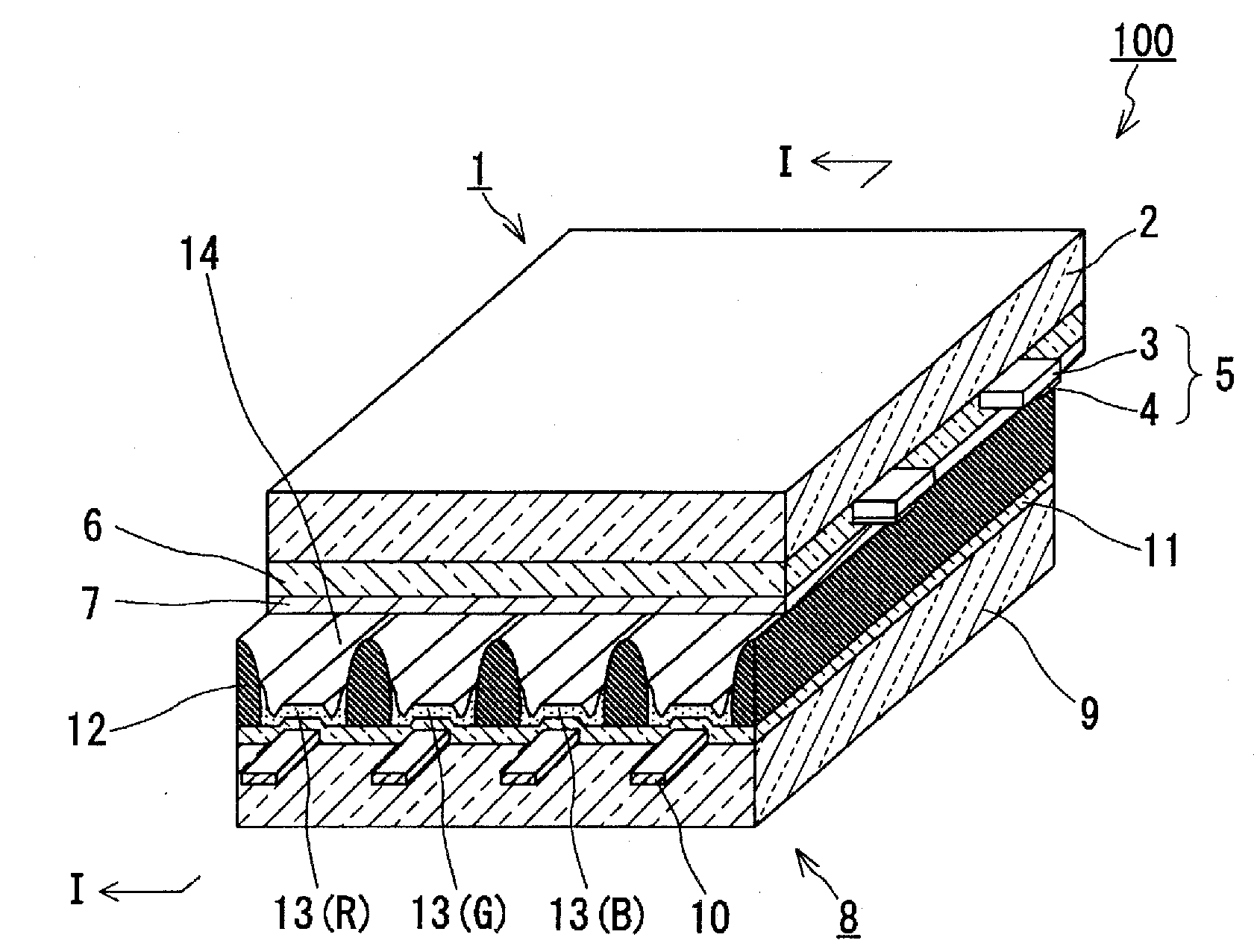

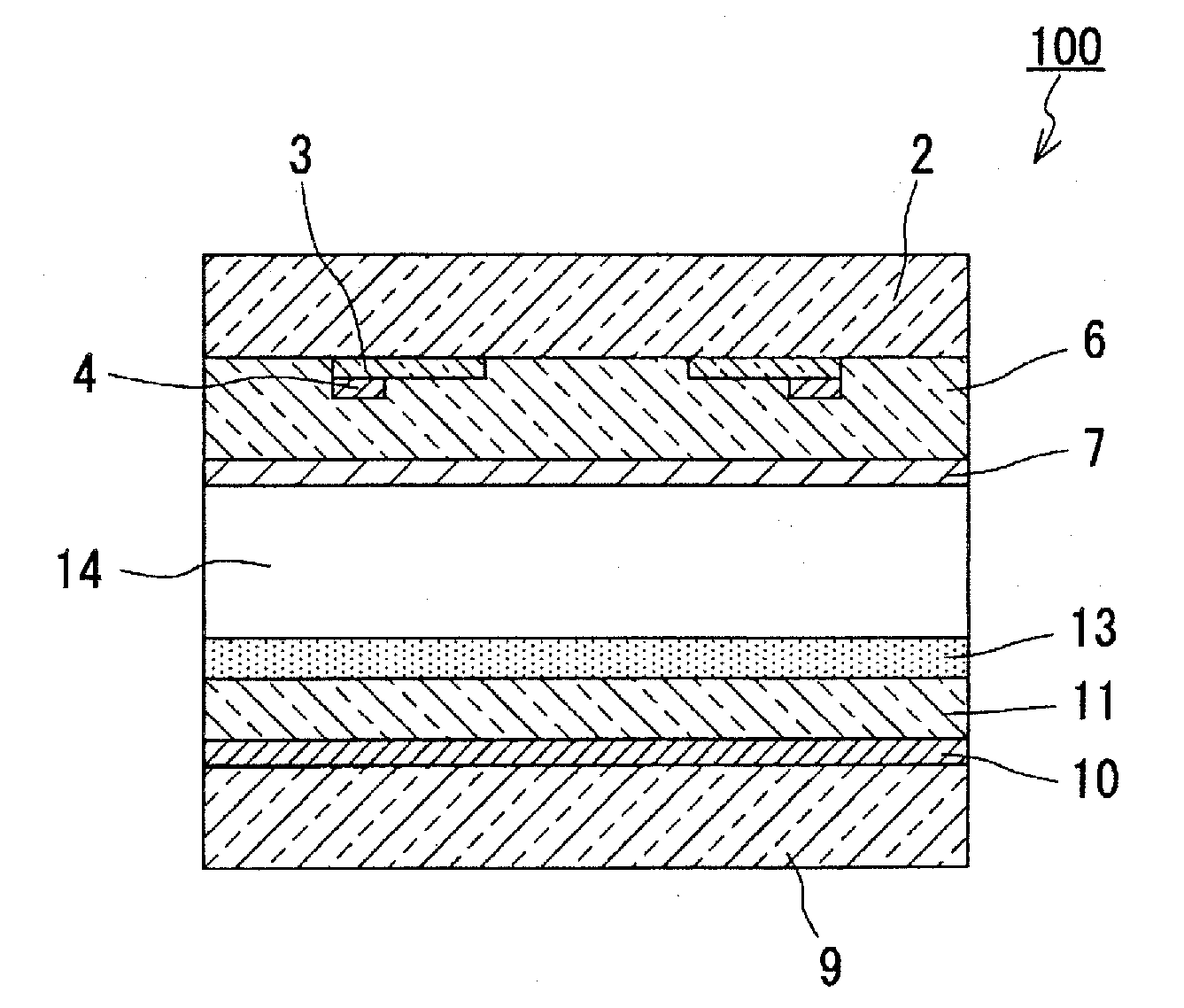

[0061] figure 1 and figure 2 An example (first embodiment) of the PDP of the present invention is shown in . figure 1 is an exploded perspective view of the PDP100. figure 2 is the longitudinal section view of the PDP100 (along figure 1 Sectional drawing of line 1-1).

[0062] like figure 1 and 2 As shown, the PDP 100 has a front panel 1 and a rear panel 8 . A discharge space 14 is formed between the front panel 1 and the rear panel 8 . The PDP is an AC surface discharge type PDP, except that the protective layer 7 is made of the above compound (made from SrCeO 3 , BaCeO 3 The structure is the same as that of the PDP of the conventional example except that one or more substances selected among them, or a crystalline oxide composed of a solid solution of these substances are used as the electron releasing material.

[0063] The front panel 1 includes: a front g...

no. 2 Embodiment approach

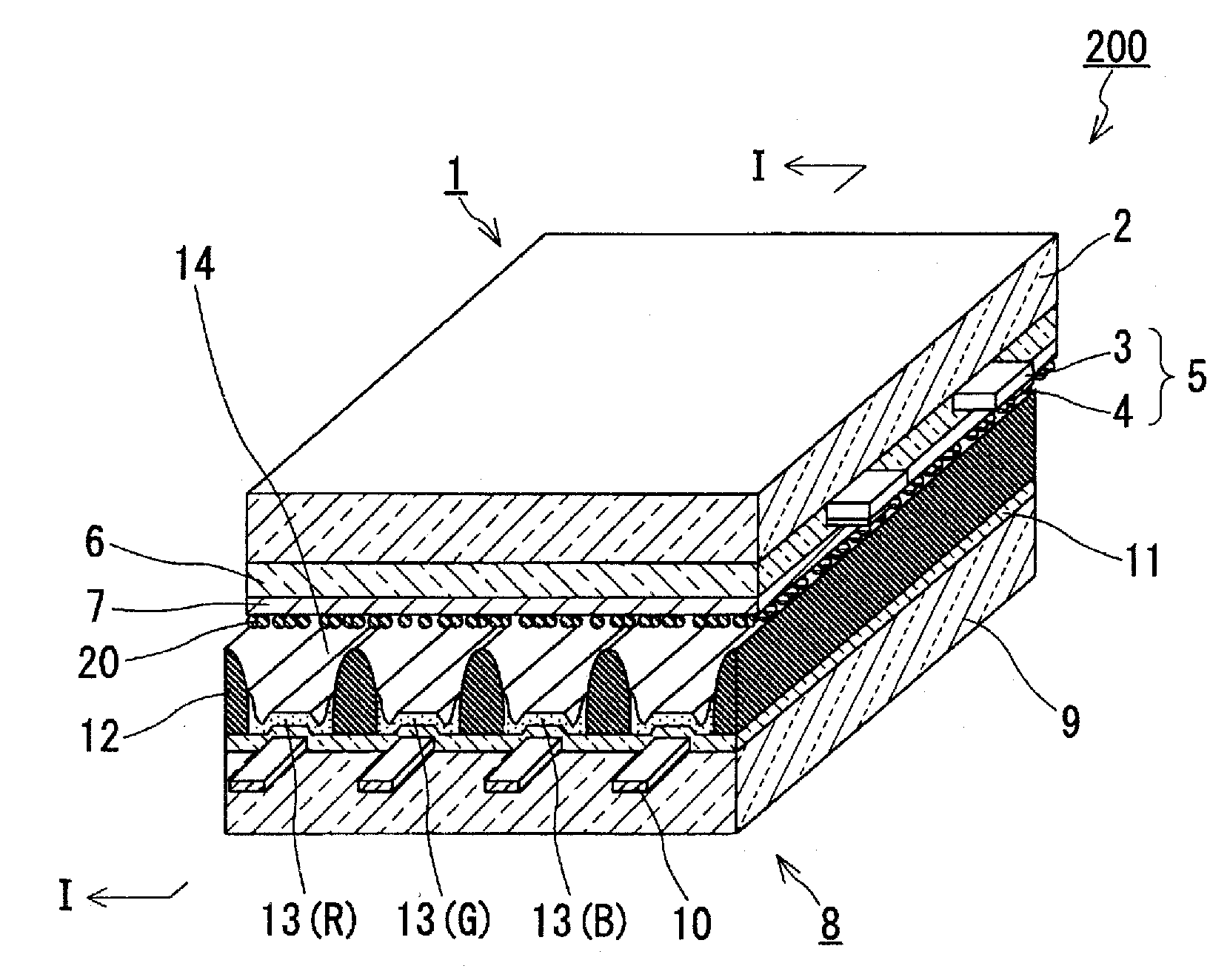

[0074] below, in image 3 and Figure 4 Another example (second embodiment) of the PDP of the present invention is shown in . image 3 is an exploded perspective view of the PDP200. Figure 4 is the longitudinal section view of the PDP200 (along image 3 sectional view of the I-I line).

[0075] The PDP 200 has the same structure as the PDP 100 except that the protective layer 7 is made of MgO and the compound powder 20 is arranged on the protective layer 7 in the form of particles. In PDP 200 , compound powder 20 also faces discharge space 14 and is arranged so as to face discharge space 14 .

[0076] Also in PDP 200 having such a structure, the same excellent image display performance as PDP 100 can be achieved and the effect of low-power driving can be achieved. In addition, the use of the protective layer 7 made of MgO also has various characteristics of the layer 7 (protection effect and long life of the dielectric layer 6 realized by good ion impact resistance perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com