Super-gravity hydrothermal reaction device

A hydrothermal reaction and supergravity technology, which is applied in chemical/physical/physical chemical mobile reactors, methods of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., can solve the problem of non-equilibrium Problems such as physical phase and material, to achieve the effect of easy industrialized large-scale production, simple equipment, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

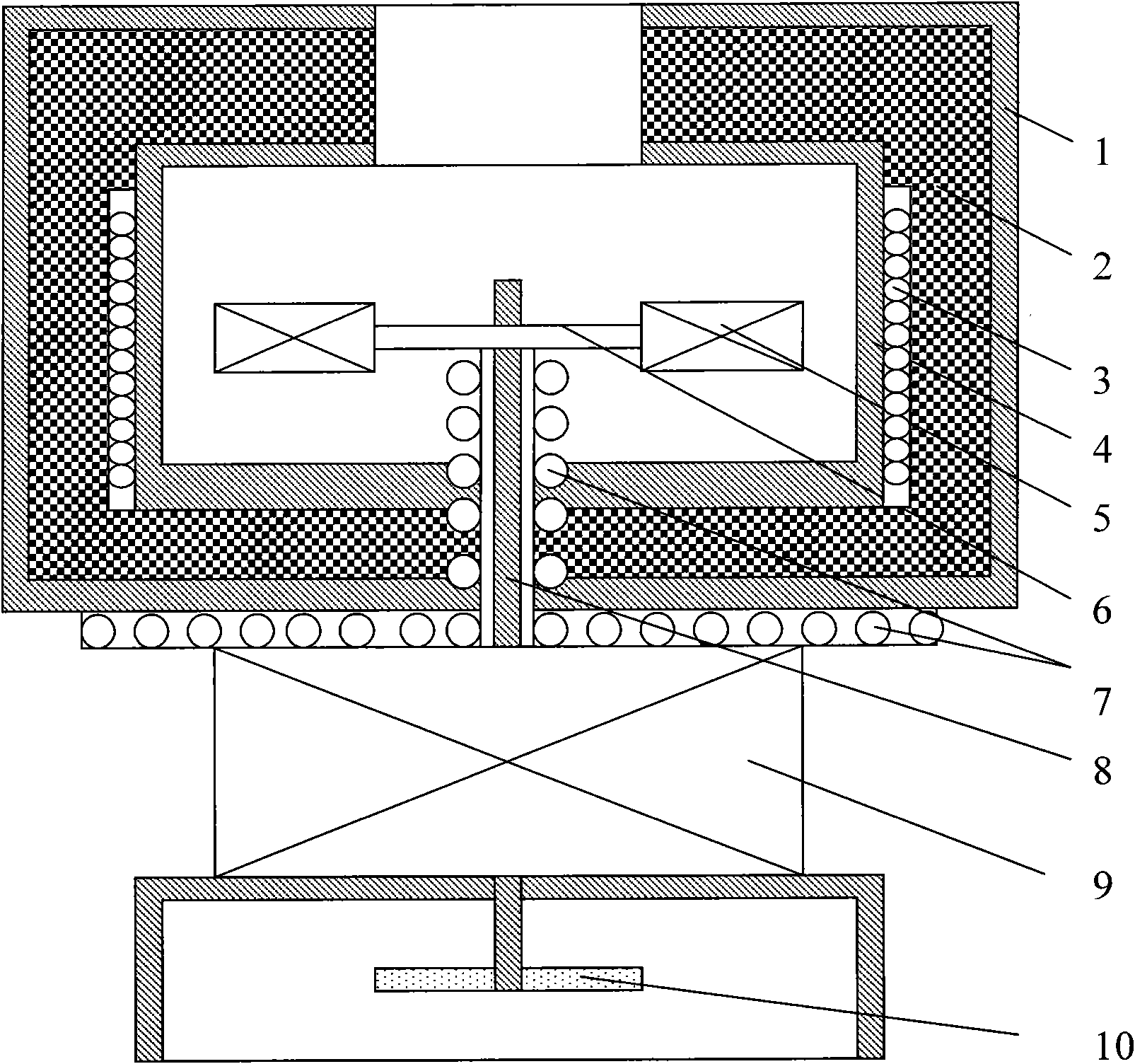

[0032] figure 1 It is a structural schematic diagram of a high-gravity hydrothermal reaction equipment. Its structure includes a centrifugal device, a temperature-controlled furnace and a high-pressure reactor, wherein the centrifugal device includes a motor (9), a rotating shaft (8), a centrifugal support (6), a cooling pipe (7) and a riot-proof cylinder (4), wherein the cooling pipe Wound around the rotating shaft and the motor; the temperature-controlled furnace includes electric heating wires (3), insulating ceramics (3), insulating bricks (2) and a casing (1), wherein the electric heating wires are wound in the insulating ceramics. Insulation materials are filled between the insulating ceramics wound with electric heating wires and the shell of the furnace body. The rotating shaft in the centrifugal device extends from the bottom of the temperature-controlled furnace to the middle of the cavity of the temperature-controlled furnace, and the centrifugal support of the cen...

Embodiment 2

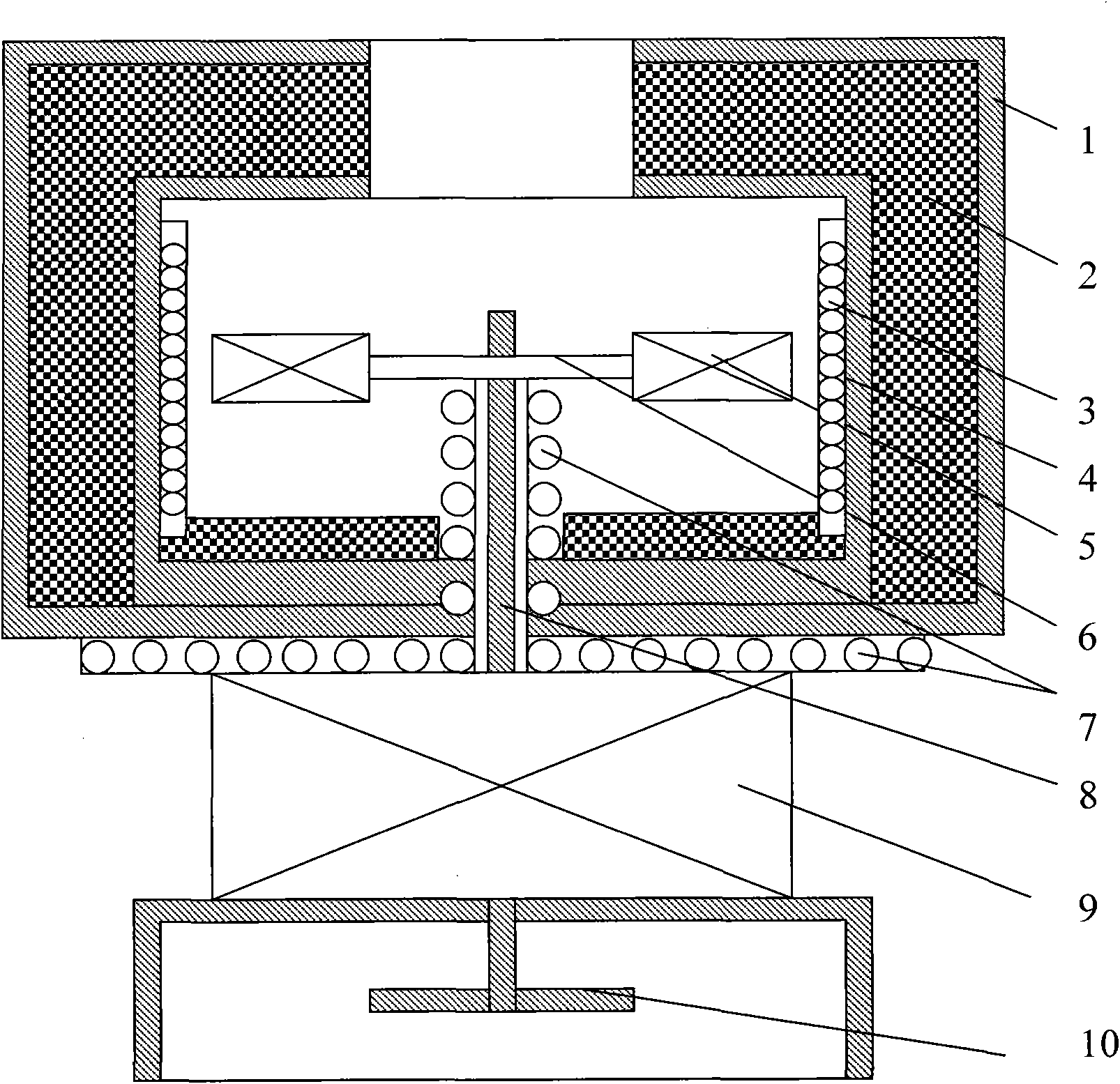

[0034] figure 2 It is a structural schematic diagram of another high-gravity hydrothermal reaction equipment. Its structure includes a centrifugal device, a temperature-controlled furnace and a high-pressure reactor, wherein the centrifugal device includes a motor (9), a rotating shaft (8), a centrifugal support (6), a cooling pipe (7) and a riot-proof cylinder (4), wherein the cooling pipe Wound around the rotating shaft and the motor; the temperature-controlled furnace includes electric heating wires (3), insulating ceramics (3), insulating bricks (2) and a casing (1), wherein the electric heating wires are wound in the insulating ceramics. Insulation materials are filled between the insulating ceramics wound with electric heating wires and the shell of the furnace body. The rotating shaft in the centrifugal device extends from the bottom of the temperature-controlled furnace to the middle of the cavity of the temperature-controlled furnace, and the centrifugal support of ...

Embodiment 3

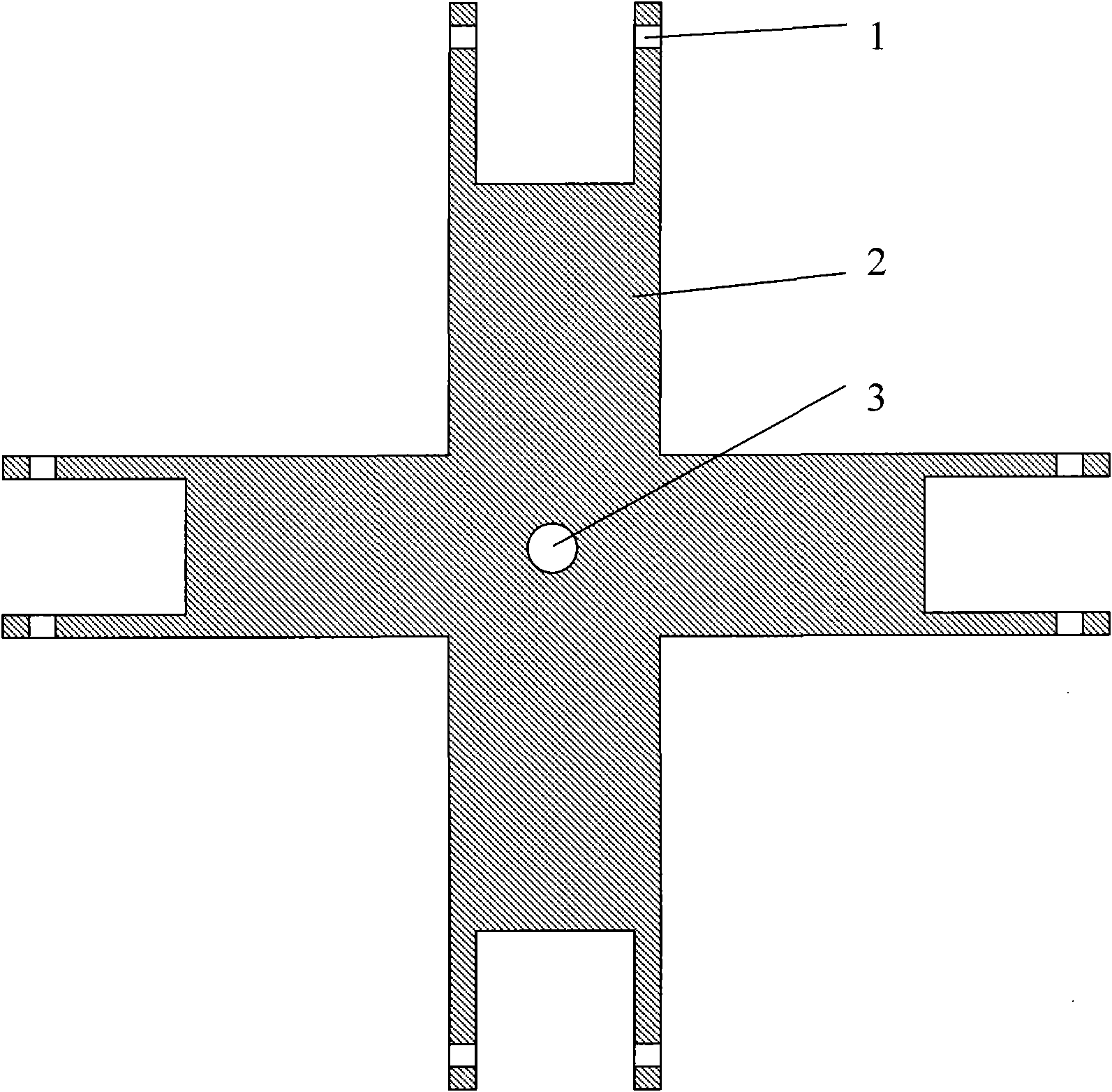

[0036] image 3 It is a schematic diagram of the centrifugal support structure of the centrifugal device. Its structure includes a card slot, a support and a rotating shaft core. The centrifugal support is made of light materials with high tensile strength, such as alloy steel and silicon carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com