Solid-liquid phase continuous compounding device for stainless steel compound plate slabs

A composite slab and composite device technology, which is applied in the field of solid-liquid phase continuous composite devices, can solve the problems of quality defects that are difficult to cast composite slabs, unavoidable surface quality problems, liquid metal and roll bonding, etc. The effect of solid-liquid interface, avoiding the mixing of steel at the interface, and improving the surface quality of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is specifically described below with an embodiment, which is only an application example of the utility model, and cannot be interpreted as limiting the protection scope of the claims of the utility model.

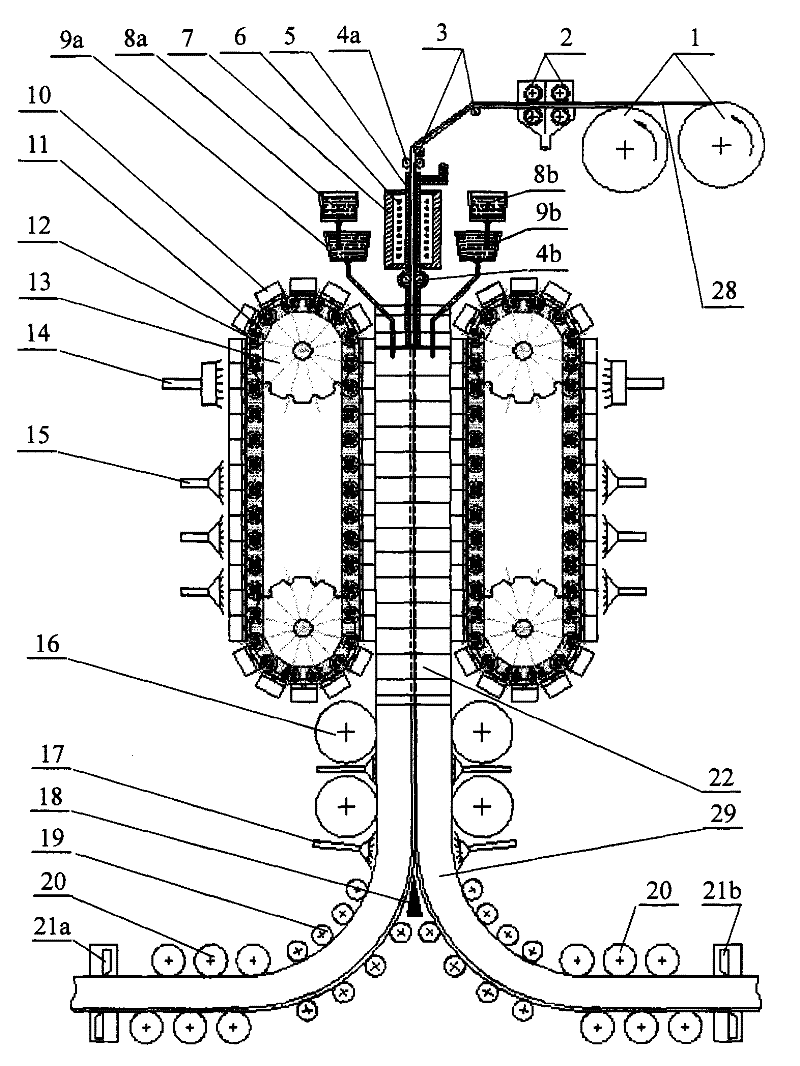

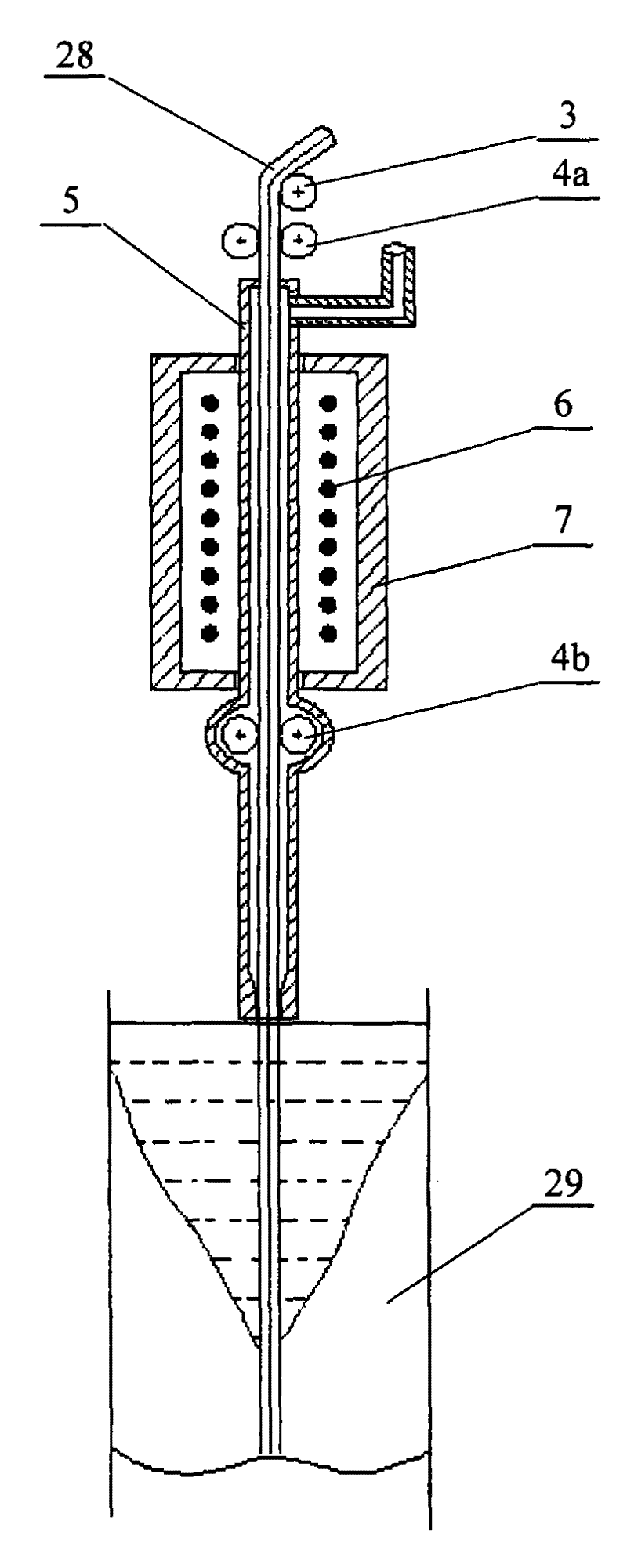

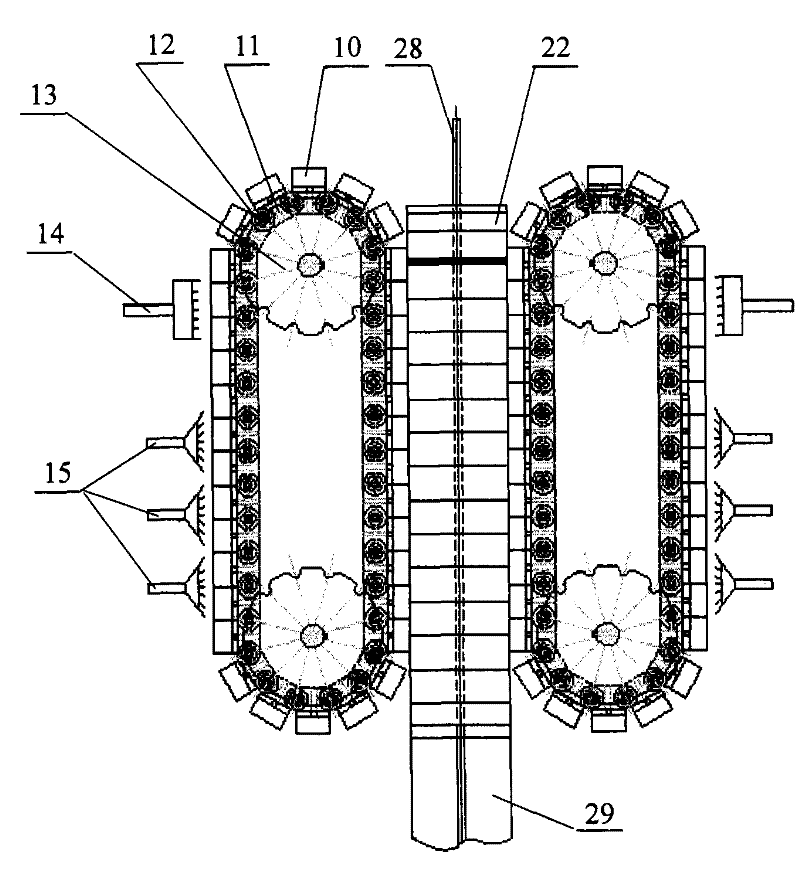

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the solid-liquid phase continuous composite device for stainless steel composite slabs includes an uncoiler 1, a wire brush 2, a guide roller 3, a casting system, a protective atmosphere heating system, a crawler crystallizer, and a cooling partition system. There are two uncoilers 1, which are staggered and arranged at the feeding position. They are used to unwind two rolls of stainless steel strips. Two wire brushes 2 are arranged behind the uncoiler 1 to clean the two outer surfaces of the stainless steel strips to be compounded. The guide roller 3 is arranged behind the wire brush and guides the stainless steel belt 28 into the protective atmosphere heating system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com