Ultra-high molecular weight polyethylene resin composition

A polyethylene resin, ultra-high molecular weight technology, applied in the direction of single-component polyolefin rayon, etc., can solve the problems of low strength, unstable fiber performance, easy fiber breakage, etc., to achieve stable performance, good spinning effect, The effect of high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

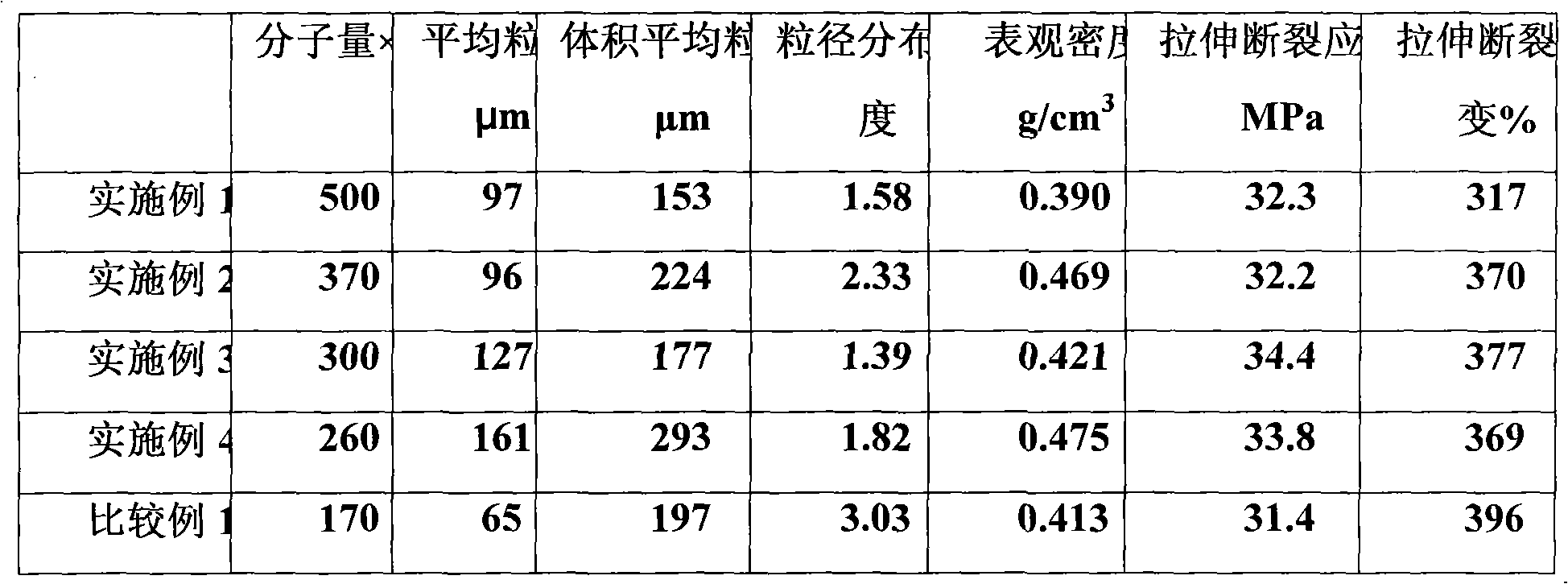

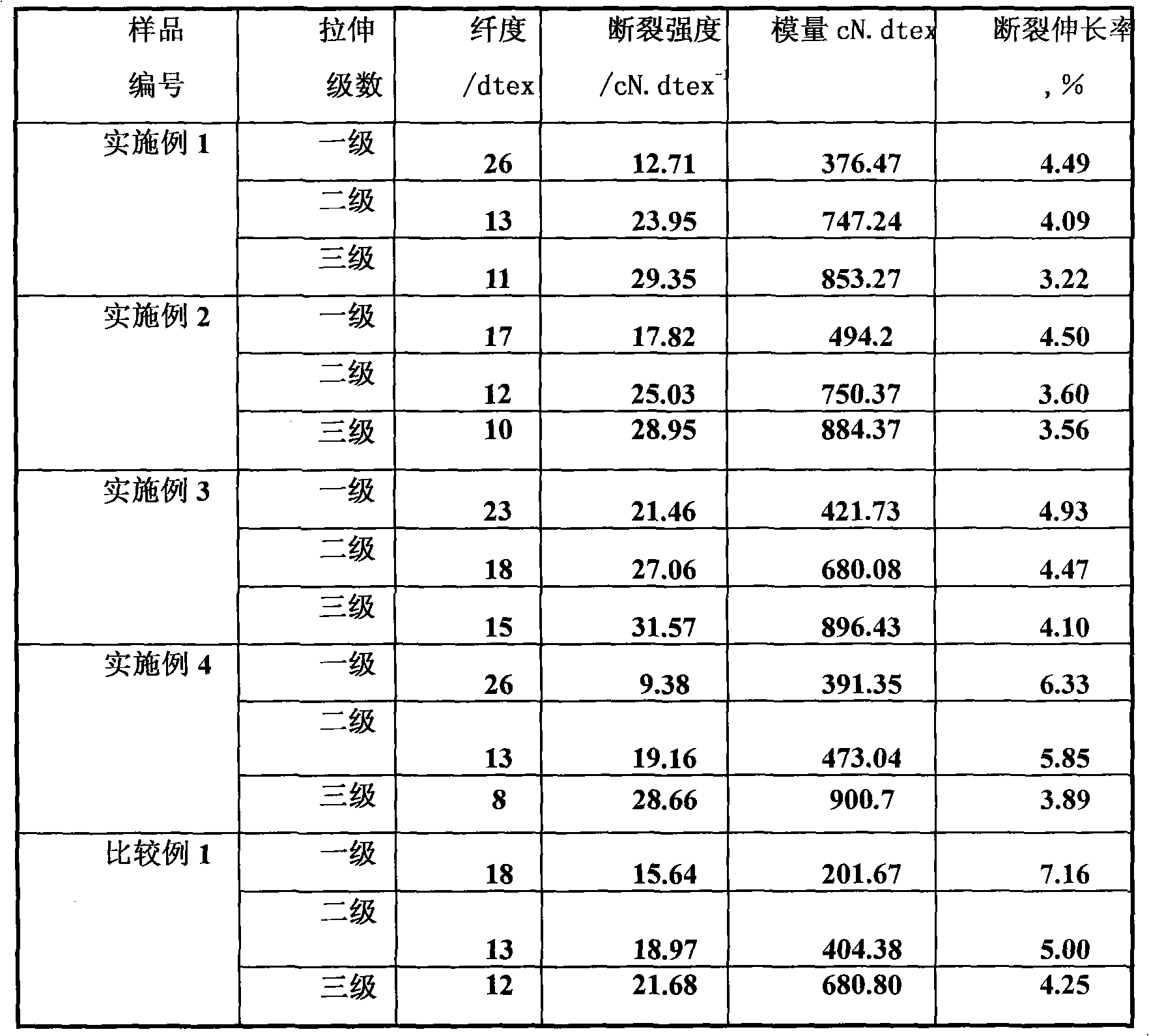

Examples

Embodiment 1

[0021] Component A: Ultra-high molecular weight polyethylene resin, weight fraction: 100 parts; Component B: tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, weight fraction: 0.5 servings.

Embodiment 2

[0023] Component A: Ultra-high molecular weight polyethylene resin, weight fraction: 100 parts; Component B: tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, weight fraction: 0.2 parts; component C: calcium stearate, weight fraction: 0.03.

Embodiment 3

[0025] Component A: Ultra-high molecular weight polyethylene resin, weight fraction: 100 parts; Component B: tris(2,4-di-tert-butylphenyl) phosphite, weight fraction: 0.3 parts; Component C: stearin Calcium acid, weight fraction: 0.06.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com