Preparation method and application of immobilized acidic urease membrane

A technology of acid urease enzyme film and acid urease, which is applied to the preparation of alcoholic beverages, fixed on/in organic carriers, hydrolytic enzymes, etc., can solve the problems of difficult long-term storage, application restrictions, and difficult reuse, and achieve High urea removal rate, easy recycling, and the effect of reducing urea content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

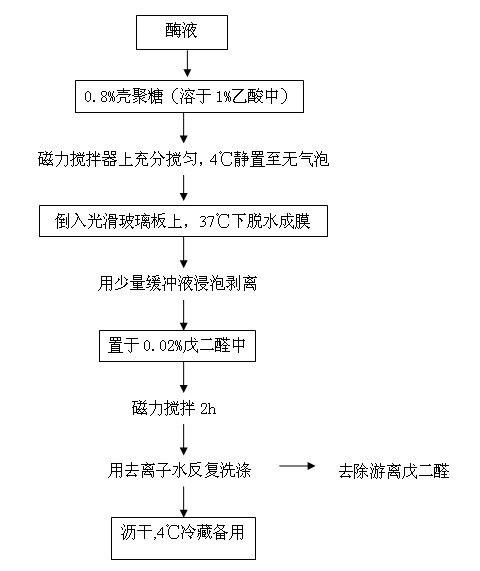

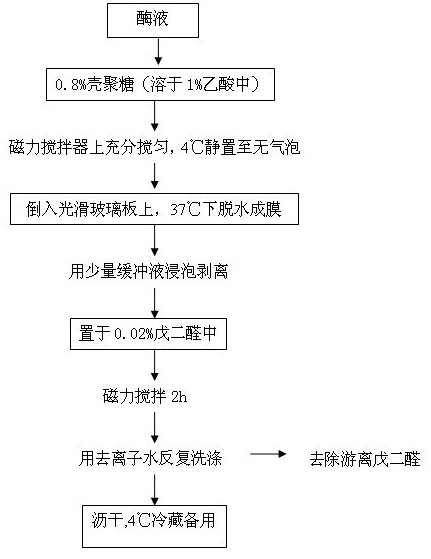

[0046] Example 1: Dissolve 4 mL of acid urease in 100 mL of 0.8% chitosan solution, stir well with a glass rod, and place in a refrigerator at 4°C until there are no bubbles in the solution. 2 amount

[0047] Pour into a smooth glass plate, dry at 37°C to form a film, soak in a small amount of citric acid buffer solution, peel off, drain, cut the film into squares of uniform size, place in 0.02% glutaraldehyde solution, and place under magnetic force Magnetically stir on the stirrer for 2 hours (cover with an opaque container to prevent glutaraldehyde from changing color when exposed to light), wash with deionized water to remove free glutaraldehyde (detected by UV spectrophotometry), drain, refrigerate for later use, and immobilize Acid urease enzymatic membrane. Take a 10 cm×10 cm membrane, put it into 100mL rice wine, and act for 24 hours at 37°C to measure the urea content in the rice wine and calculate the urea removal rate. rate reached 73%.

Embodiment 2

[0048] Example 2: Dissolve 4 mL of acid urease in 100 mL of 0.8% chitosan solution, stir thoroughly with a glass rod, and place in a refrigerator at 4°C until there are no bubbles in the solution. 2 Pour the amount into a smooth glass plate, dry at 37°C to form a film, soak in a small amount of citric acid buffer solution, peel off, drain, cut the film into squares of uniform size, place in 0.02% glutaraldehyde solution, and place Stir magnetically on a magnetic stirrer for 2 hours (cover with an opaque container to prevent glutaraldehyde from changing color when exposed to light), wash with deionized water to remove free glutaraldehyde (detected by ultraviolet spectrophotometry), drain, and refrigerate for later use to obtain Immobilized acid urease enzyme membrane. Take a 4 cm × 4 cm membrane, put it into 100 mL of rice wine, and let it act for 24 hours at 37 ° C to measure the urea content and calculate the urea removal rate. The urea content dropped from 24.8mg / L to 9.6mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com