Method for preparing graphene film with single atomic layer

A technology of monoatomic layer graphite and atomic layer deposition, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of uniform graphene material, poor quality of graphene, graphite layer damage, etc., to achieve The effect of complete structure, uniform thickness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of monoatomic layer graphene film, comprises the steps:

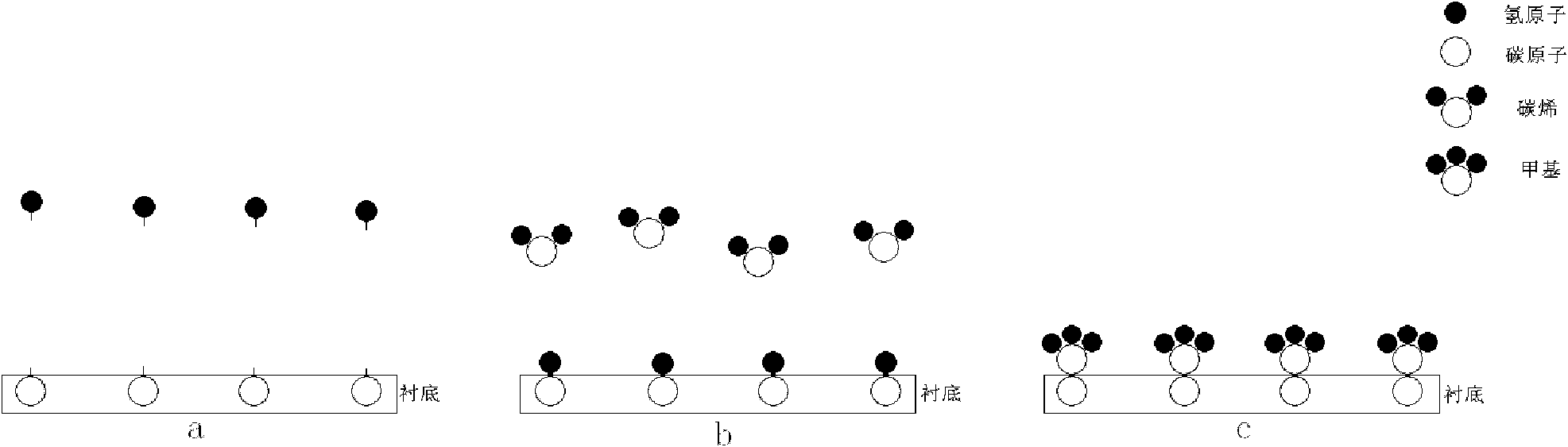

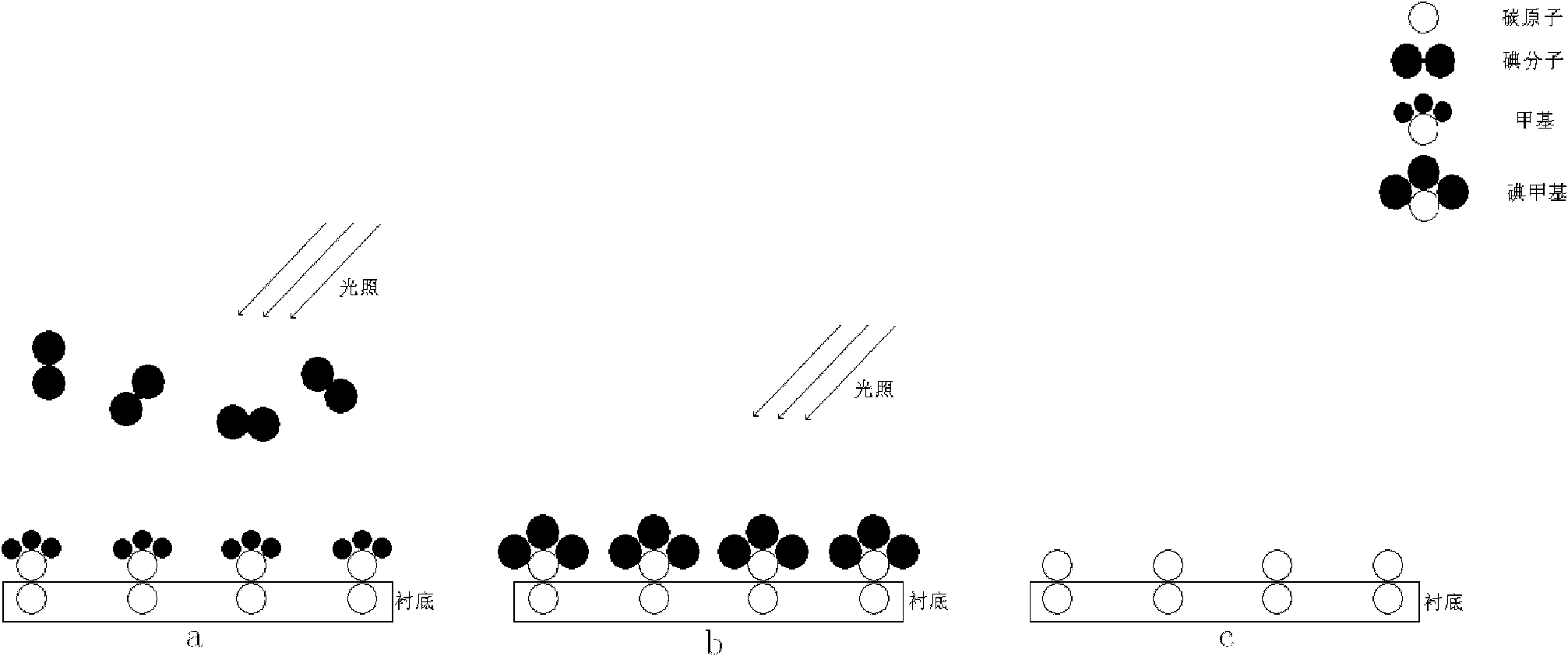

[0031] Step 101, under the plasma condition of 200°C, hydrogen gas is introduced for 5 minutes, and the (0001) crystal plane and the silicon carbide substrate terminated by carbon atoms are hydrogenated to form a C-H bond on the surface of the silicon carbide substrate, such as figure 1 As shown in figure a in the middle; the silicon carbide substrate after hydrogenation treatment is placed in the reaction chamber of the atomic layer deposition equipment;

[0032] Step 102, injecting argon gas with a concentration of 99.99% into the reaction chamber of the atomic layer deposition equipment for 5 minutes to clean the reaction chamber; Light irradiation decomposes diazomethane, and the decomposition products have unbonded electrons. The chemical expression of diazomethane decomposition is:

[0033] Such as figure 1 As shown in Figure b;

[0034] The decomposition product carbene (:...

Embodiment 2

[0038] A kind of preparation method of monoatomic layer graphene film, comprises the steps:

[0039] Step 101, under the plasma condition of 300°C, hydrogen gas is introduced for 10 minutes, and the silicon carbide substrate with the (0001) crystal plane terminated by carbon atoms is subjected to hydrogenation treatment, so that the surface of the silicon carbide substrate forms a C-H bond, such as figure 1 As shown in figure a in the middle; the silicon carbide substrate after hydrogenation treatment is placed in the reaction chamber of the atomic layer deposition equipment;

[0040] Step 102, injecting argon gas with a concentration of 99.99% into the reaction chamber of the atomic layer deposition equipment for 10 minutes to clean the reaction chamber; Light irradiation decomposes diazomethane, and the decomposition products have unbonded electrons. The chemical expression of diazomethane decomposition is:

[0041] Such as figure 1 As shown in Figure b;

[0042] The de...

Embodiment 3

[0046] A kind of preparation method of monoatomic layer graphene film, comprises the steps:

[0047] Step 101, under the plasma condition of 400°C, hydrogen gas is introduced for 15 minutes, and the silicon carbide substrate with the (0001) crystal plane terminated by carbon atoms is subjected to hydrogenation treatment, so that the surface of the silicon carbide substrate forms a C-H bond, such as figure 1 As shown in figure a in the middle; the silicon carbide substrate after hydrogenation treatment is placed in the reaction chamber of the atomic layer deposition equipment;

[0048] Step 102, injecting argon gas with a concentration of 99.99% into the reaction chamber of the atomic layer deposition equipment for 15 minutes to clean the reaction chamber; Light irradiation decomposes diazomethane, and the decomposition products have unbonded electrons. The chemical expression of diazomethane decomposition is:

[0049] Such as figure 1 As shown in Figure b;

[0050] The de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com