Heating system and method by using power plant steam turbine bearing cooling water through heat pump

A cooling system and heating system technology, applied in hot water central heating system, heating system, heat recovery system, etc., can solve the problems of poor cooling effect, waste of heat, and bearing cooling affecting the operation of steam turbine units, etc., to improve boiler feed water temperature, the effect of reducing the bearing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

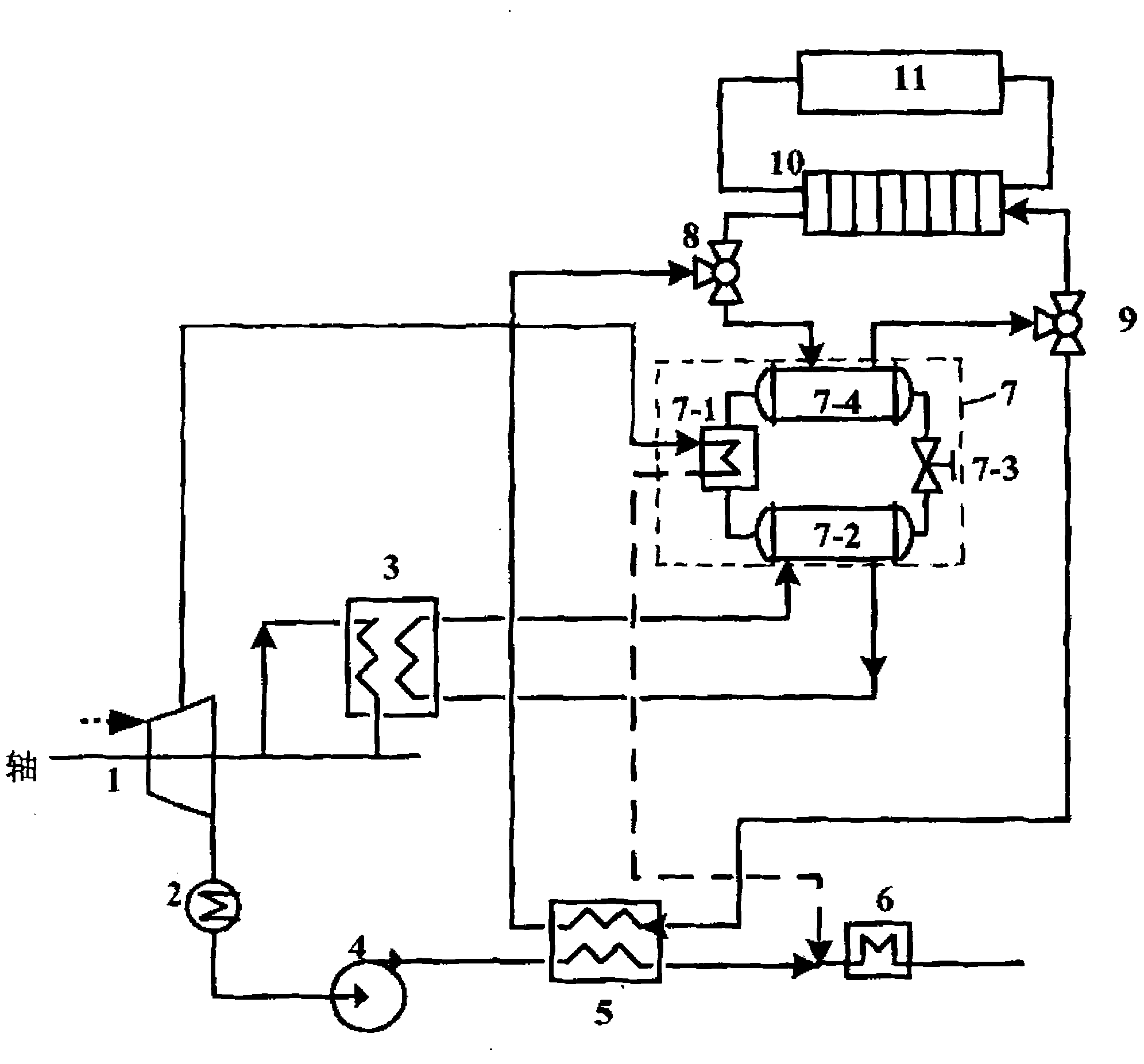

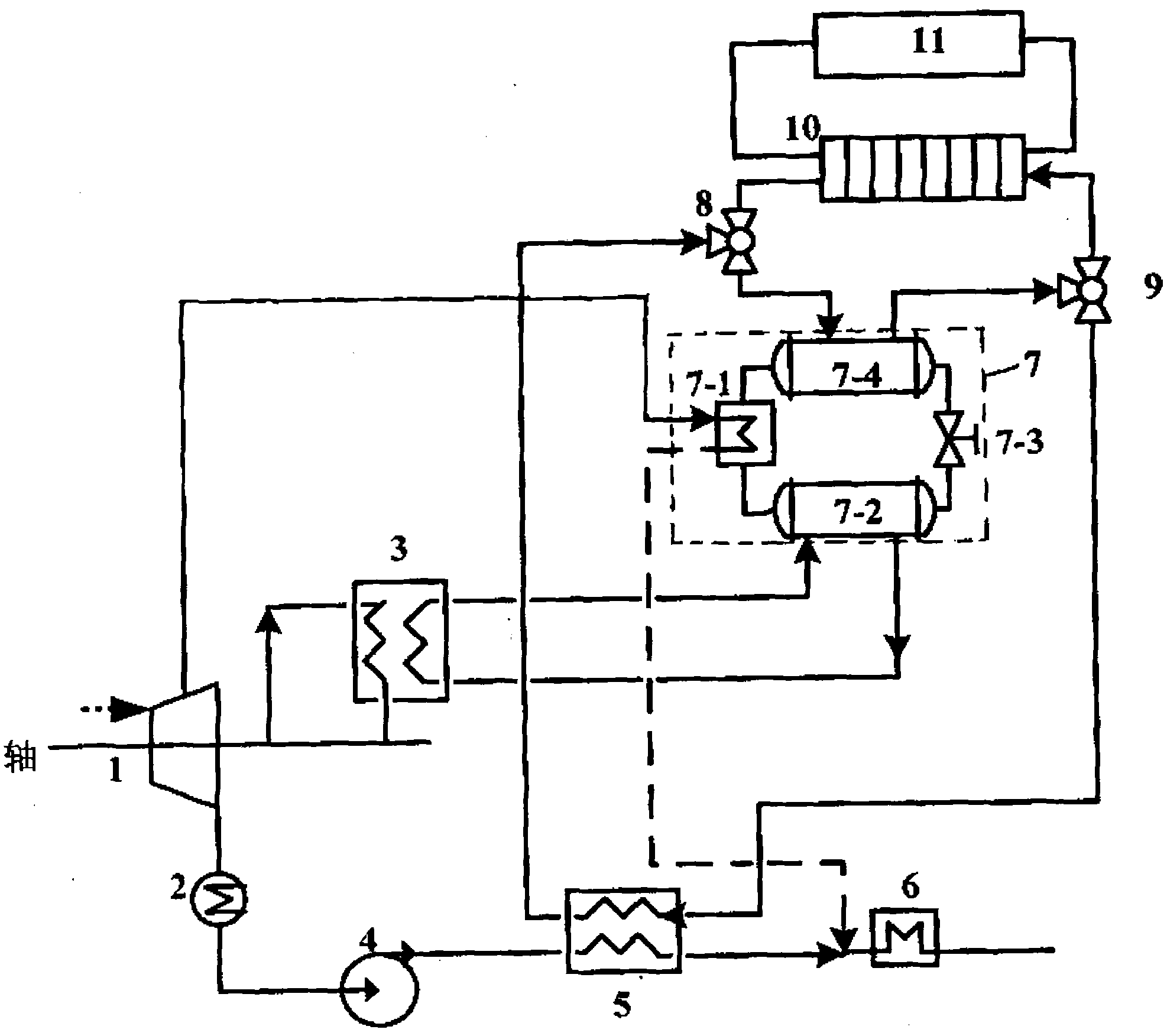

[0012] figure 1 It is a schematic diagram of the heating system structure of the steam turbine unit bearing cooling water heat pump. The system includes steam turbine, condenser, steam turbine bearing cooling system, steam absorption heat pump, condensate pump, water-water heat exchanger, low-pressure heater, supply and return water Three-way valve, heating network heater and auxiliary equipment, etc., are composed of corresponding pipeline connections.

[0013] The specific working process is as follows: the exhaust steam of steam turbine 1 enters the condenser 2 to condense into water, and then is sent to the boiler as feed water through the heat recovery system composed of condensate pump 4 and low-pressure heater 6; the exhaust steam released by steam turbine 1 during high-speed rotation The heat is cooled by the steam turbine bearing cooling system 3, and the circulating water cooling pipeline is connected to the evaporator 7-2 of the steam absorption heat pump 7 as the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap