Method for measuring tin element by EDTA (Ethylene Diamine Tetraacetic Acid) complexation

A complex and elemental technology, which is applied in material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of large error in test values, interference in tin measurement, and complicated steps, etc. problems, to achieve the effect of ensuring measurement accuracy, short measurement cycle, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

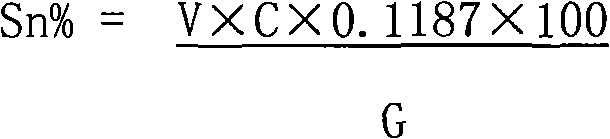

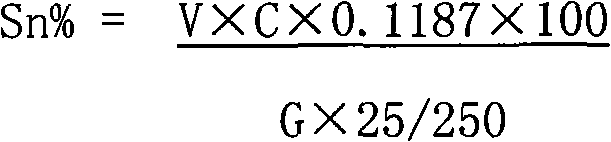

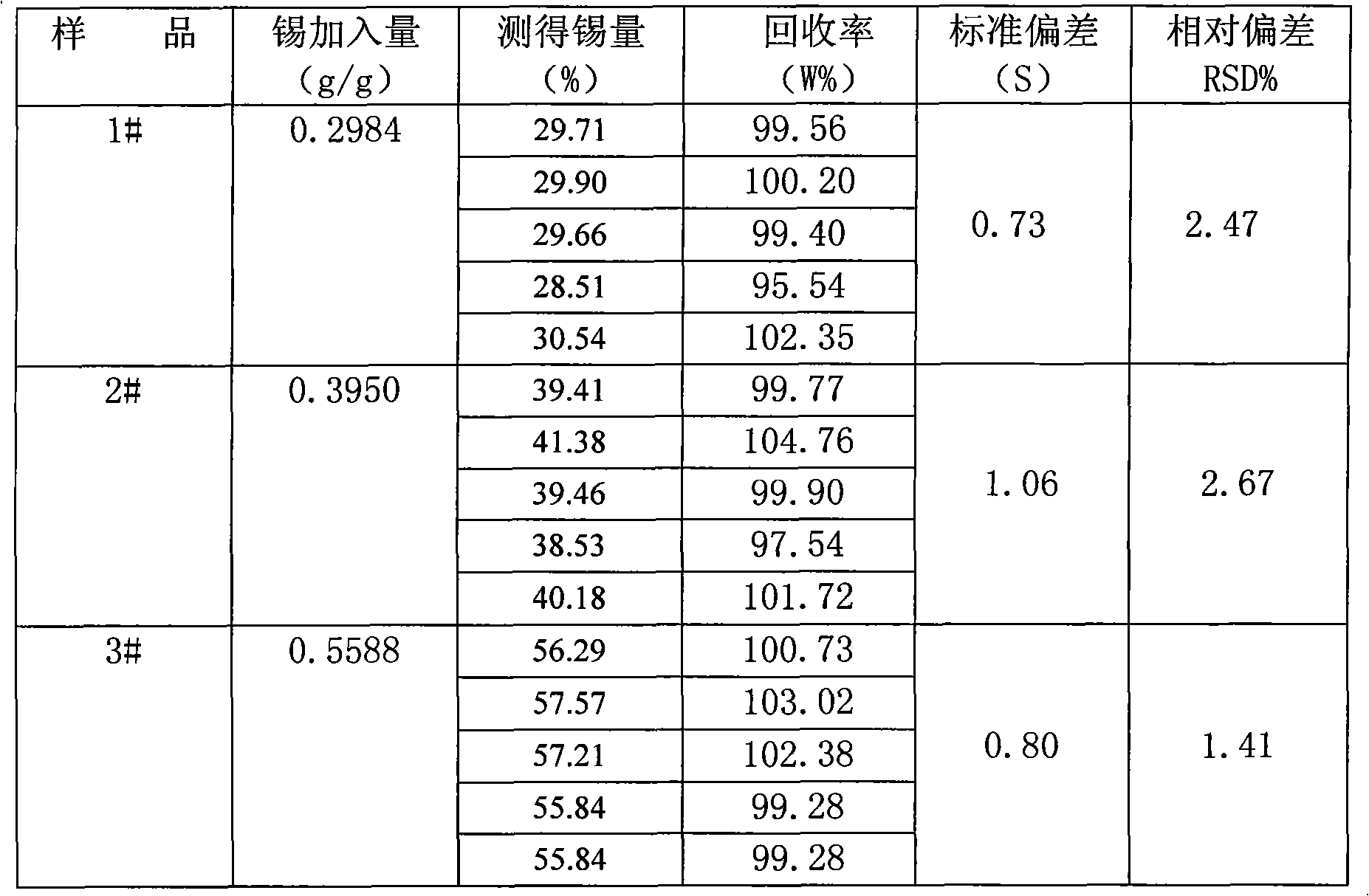

[0028] The basic principle of the method for the determination of tin element by EDTA complexation of the present invention is as follows: first, after the sample is dissolved in salt-nitrate mixed acid, under certain conditions, use xylenol orange as indicator, titrate excessive EDTA with standard titration solution, and then use Sodium fluoride destroys the complex and precipitates EDTA equivalent to the amount of tin, and then titrates with the standard titration solution, and calculates the percentage of tin according to the volume of the standard titration solution consumed in the second titration.

[0029] The method for EDTA complexation determination tin element of the present invention is described in detail below by specific embodiment, and its steps are as follows:

[0030] The first step: sample preparation,

[0031] Grind off the oxide layer on the surface of the solder with fine sandpaper and process it into chips. The processed samples should be tested as soon a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com