Transparent drop-out fuse

A fuse and transparent technology, applied in the field of transparent drop-out fuses, can solve problems such as difficult to judge fuse damage, variable type, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

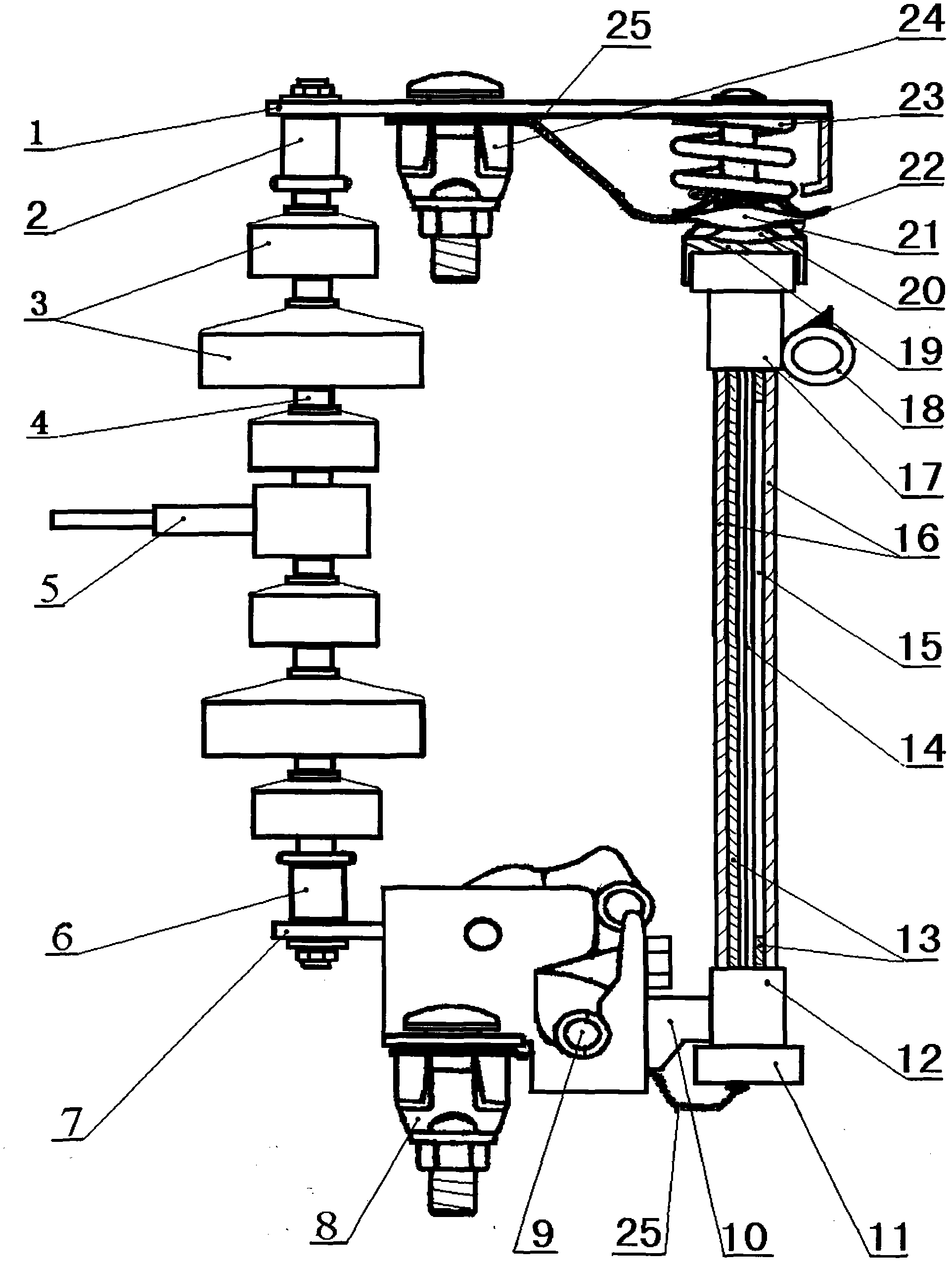

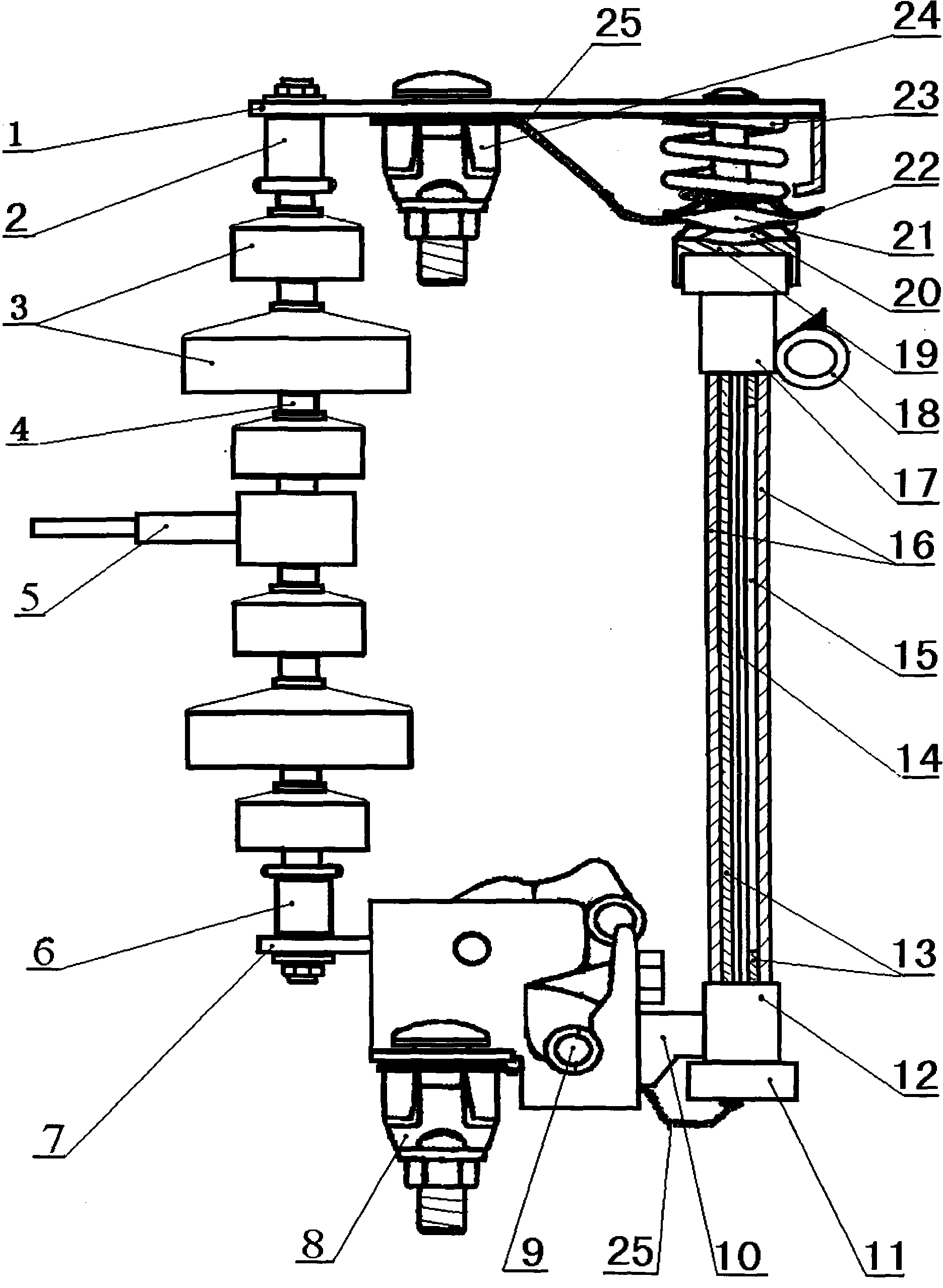

[0025] The production of the transparent drop-out fuse is to install a mounting plate 5 in the middle of the insulator 4 made of glass fiber reinforced plastic material, and the upper and lower sides are respectively equipped with transparent umbrellas 3 made of polycarbonate resin material by conventional injection molding methods, and the insulators are respectively installed The upper fitting 2, the lower fitting 6 of the insulator, the upper seat plate 1 and the lower seat plate 7, the upper seat plate 1 is installed with the upper pressing plate 24 and the spring 23, the static contact piece 22 is fixed on the shaft of the spring 23 and the pressure release cap 21 is fixed, and the release The bottom of the pressure cap 21 is welded with copper and tungsten 20 contacts, the pressure release cap 21 is connected to the upper pressure plate 24 with a copper connecting wire 25, and the lower seat plate 7 is installed with the lower pressure plate 8, the movable shaft 9 and the ...

Embodiment 2

[0028] The production of the transparent drop-out fuse is that a mounting plate 5 is arranged in the middle of the insulator 4 made of glass fiber reinforced plastic material, and the upper and lower sides are respectively equipped with transparent umbrellas 3 made of polycarbonate modified resin material by conventional injection molding methods, and respectively Set the upper fittings 2 of the insulator, the lower fittings 6 of the insulator, the upper seat plate 1 and the lower seat plate 7, the upper seat plate 1 is installed with the upper pressing plate 24 and the spring 23, the static contact piece 22 is fixed on the shaft of the spring 23 and the release cap 21 is fixed , the bottom of pressure release cap 21 is welded with copper and tungsten 20 contacts, and pressure release cap 21 is connected with upper pressure plate 24 with copper connecting wire 25, and lower seat plate 7 is installed with lower pressure plate 8, movable shaft 9 and hair plate 10, and sends out T...

Embodiment 3

[0031] The production of the transparent drop-out fuse is to install a mounting plate 5 in the middle of the insulator 4 made of glass fiber reinforced plastic material, and the upper and lower sides are respectively equipped with transparent umbrellas 3 made of polycarbonate modified resin materials by conventional injection molding methods, and respectively Set the upper fittings 2 of the insulator, the lower fittings 6 of the insulator, the upper seat plate 1 and the lower seat plate 7, the upper seat plate 1 is installed with the upper pressing plate 24 and the spring 23, the static contact piece 22 is fixed on the shaft of the spring 23 and the release cap 21 is fixed , the bottom of pressure release cap 21 is welded with copper and tungsten 20 contacts, and pressure release cap 21 is connected with upper pressure plate 24 with copper connecting wire 25, and lower seat plate 7 is installed with lower pressure plate 8, movable shaft 9 and hair plate 10, and sends out The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com