Device and method for treating oil-containing sewage of oil field by adopting plant filter materials

A plant filter material and oily sewage technology, applied in the direction of grease/oily substance/suspton removal device, separation method, chemical instrument and method, etc., can solve the problem of low efficiency, achieve the effect of protecting the environment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 uses reed straw as the raw material of plant filter material

[0027] 1) Cleaning step: first, the reed stalks of Poaceae are cleaned with water; the cleaning refers to washing away impurities such as silt and dirt on the surface of raw materials with water, otherwise the flow resistance during filtration will be increased and energy will be consumed;

[0028] 2) Drying step: then drying the cleaned reeds in the sun so that the moisture content in the reed stalks does not exceed 4%;

[0029] 3) Crushing and sieving steps: crush the dried reed straw with a pulverizer to obtain particles of different sizes and diameters, and then sieve with 80-mesh and 28-mesh standard sampling sieves to obtain reeds of 200 μm-600 μm straw filter.

Embodiment 2

[0030] Embodiment 2 uses wheat straw as the raw material of plant filter material

[0031] 1) Cleaning step: firstly, the wheat straw is cleaned with water;

[0032] 2) Drying step: then exposing the cleaned wheat stalks to the sun so that the moisture content of the wheat stalks does not exceed 4%;

[0033] 3) Grinding and sieving steps: Grinding the dried wheat straw with a pulverizer to obtain particles of different sizes and diameters, and then sieving with 80-mesh and 28-mesh standard sampling sieves to obtain 200 μm-600 μm wheat straw straw filter.

[0034] Straws of other Gramineae can also be used to prepare plant filter materials, for example, rice straw and corn stalks can be made into rice straw filter materials and corn stalk filter materials respectively.

Embodiment 3

[0035] Embodiment 3 uses wood powder as the raw material of plant filter material

[0036] 1) Cleaning step: firstly wash the Chinese fir powder with water;

[0037] 2) Drying step: drying the cleaned Chinese fir powder in an oven at 70°C so that the water content in the Chinese fir powder does not exceed 3%;

[0038] 3) Crushing and sieving steps: crush the dried fir powder with a pulverizer to obtain particles of different sizes and diameters, and then sieve with 80-mesh and 28-mesh standard sample sieves to obtain 200 μm-600 μm Chinese fir powder filter.

[0039] Other wood powders can also be used as plant filter materials, for example: poplar wood powder, pine wood powder, etc. are made into poplar wood powder filter material and pine wood powder filter material.

[0040] 2. The prepared plant filter material is used in the device for oily sewage treatment in oil fields

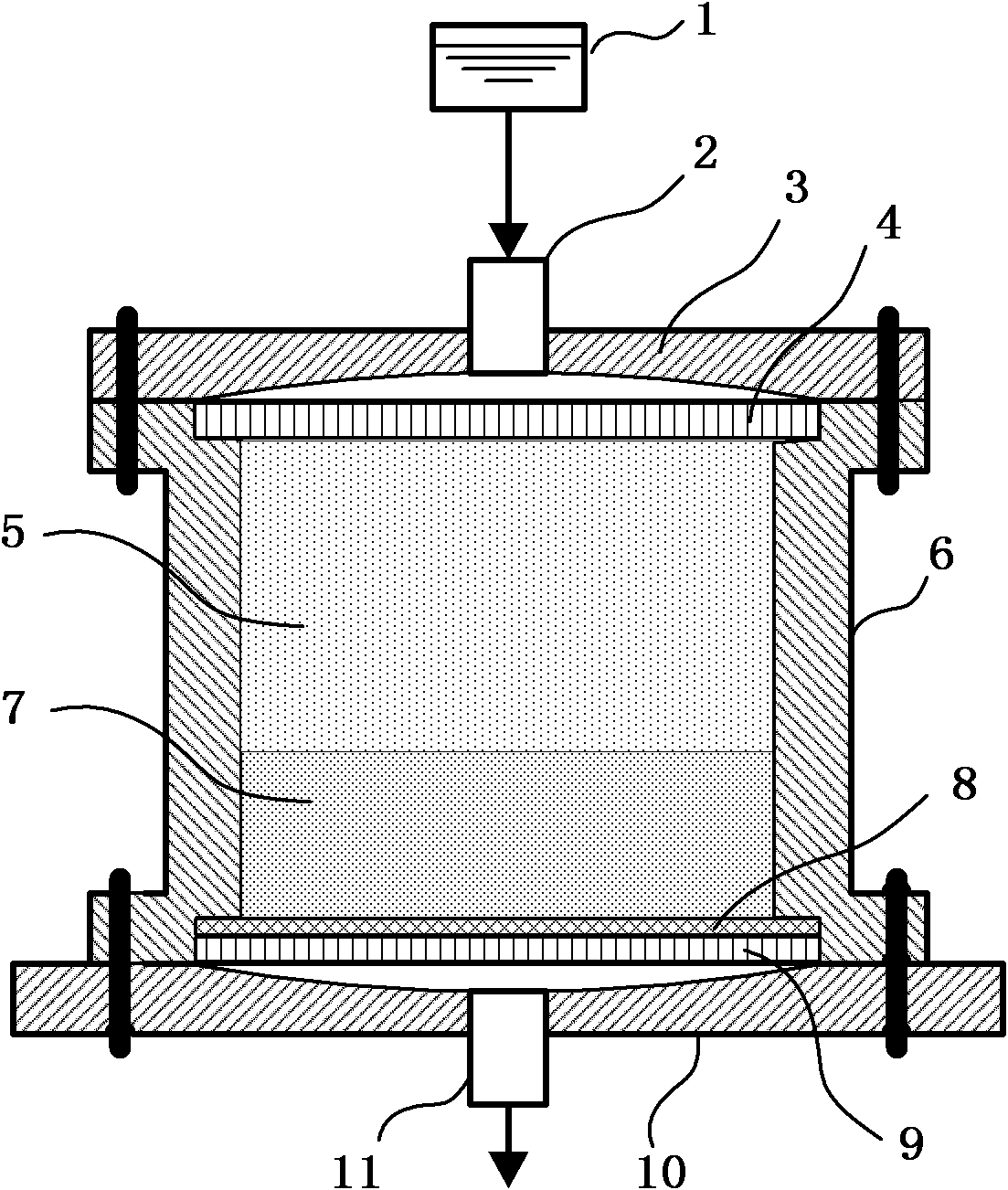

[0041] Such as figure 1 A device for using the plant filter material prepared above for the treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com