Manufacturing method of aluminium alloy workpiece with complex inner cavity body

A manufacturing method, aluminum alloy technology, applied in the direction of manufacturing tools, metal processing equipment, instruments, etc., can solve the problems of high manufacturing difficulty and low precision, and achieve the effect of low manufacturing difficulty, high precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

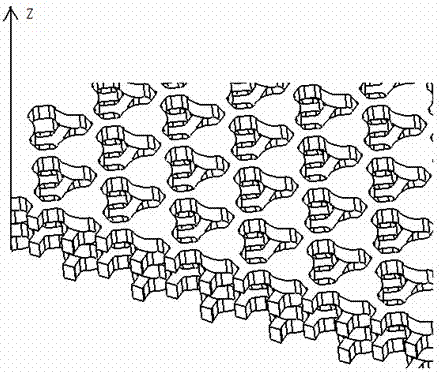

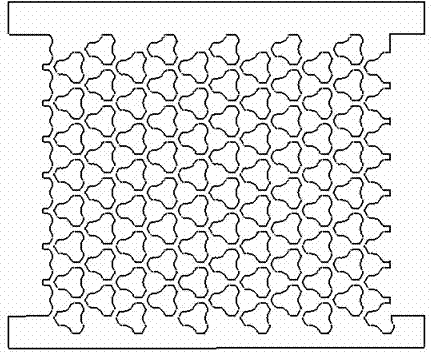

[0044] Embodiment 1: It is aimed at an aluminum alloy workpiece with a semi-closed multi-layer staggered hole-like structure inner cavity, and the z-axis is the height axis. figure 1 A schematic diagram of its three-dimensional structure, figure 2 It is a schematic diagram of the structure of a single virtual slice after cutting. The thickness between the virtual slices is divided into two types: equidistant and unequal, and the rest of the structure is the same.

[0045] A method for manufacturing an aluminum alloy workpiece with a complex inner cavity, the method sequentially includes the following steps:

[0046] The first step: first analyze the real object or design drawing of the aluminum alloy workpiece with a complex inner cavity to be manufactured, and then draw a three-dimensional diagram of the aluminum alloy workpiece on the computer, and then take the height axis of the aluminum alloy workpiece as the direction, along the hole Perform oblique isometric or non-is...

Embodiment 2

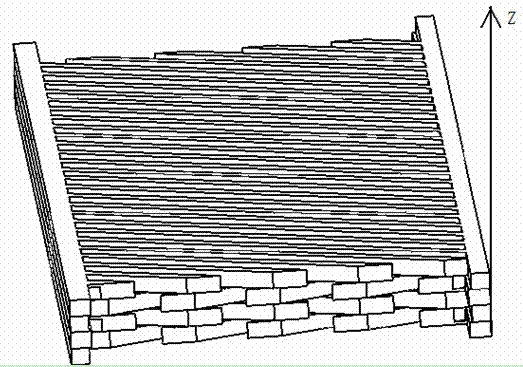

[0050] Embodiment 2: It is aimed at an aluminum alloy workpiece with a closed multi-layer interlaced sheet structure inner cavity, and the z axis is the height axis. image 3 A schematic diagram of its three-dimensional structure, Figure 4 It is a schematic diagram of the structure of a single virtual slice after cutting. The thickness between the virtual slices is divided into two types: equidistant and unequal, and the rest of the structure is the same.

[0051] A method for manufacturing an aluminum alloy workpiece with a complex inner cavity, the method includes the following steps in sequence:

[0052] The first step: first analyze the real object or design drawing of the aluminum alloy workpiece with a complex inner cavity to be manufactured, and then draw a three-dimensional diagram of the aluminum alloy workpiece on the computer, and then take the height axis of the aluminum alloy workpiece as the direction, along the sheet Horizontally equidistant or non-equidistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com