Method for extracting silicon carbide micro powder and diesel oil fuel

A technology of silicon carbide micropowder and extraction method, which is applied in the direction of only multi-stage series refining process treatment, can solve problems that have not yet been seen, and achieve the effects of avoiding leakage, saving resources and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

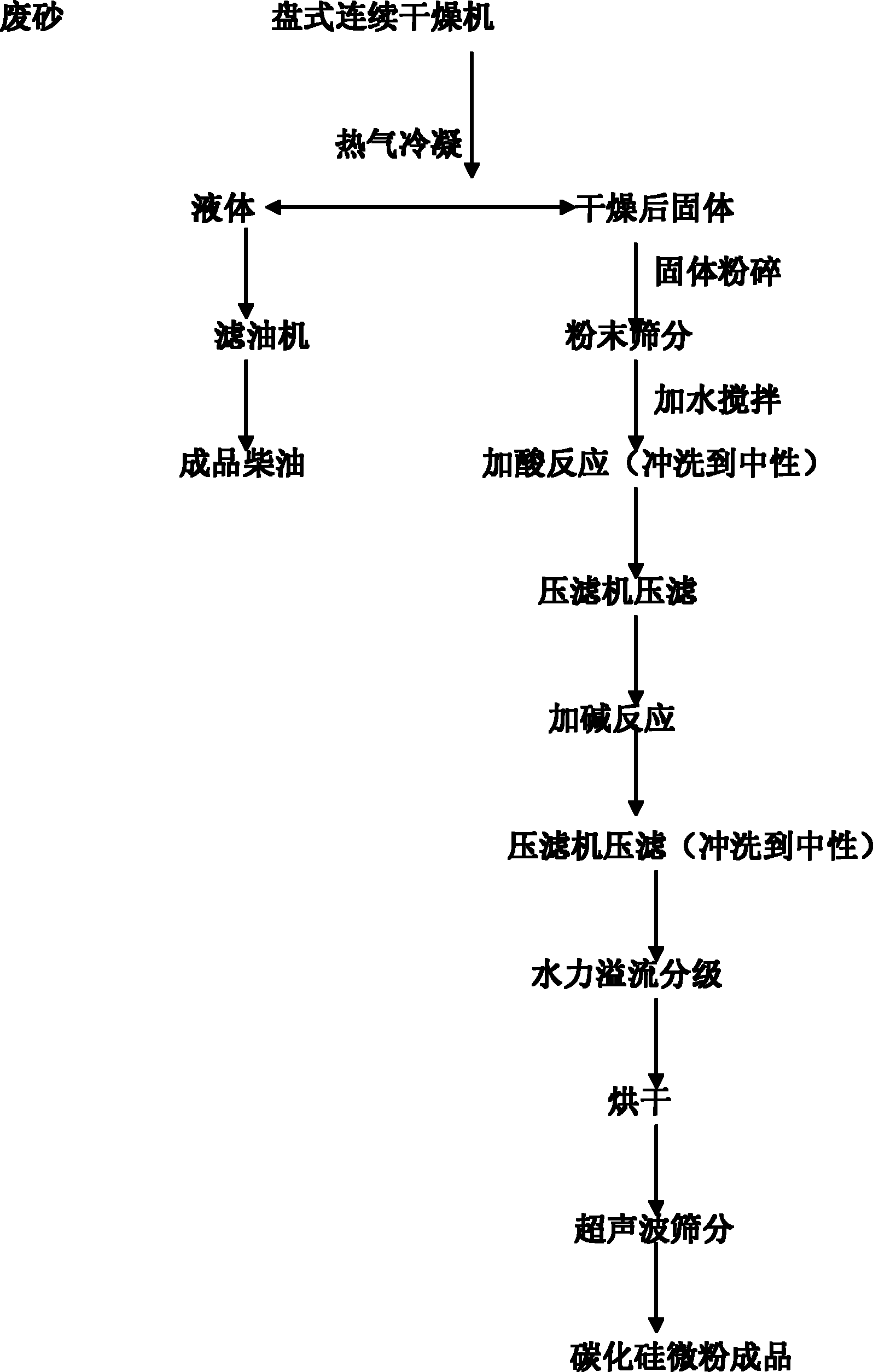

[0044] The method for extracting silicon carbide micropowder and fuel diesel oil using the waste oil sand produced in the process of crystalline silicon cutting, grinding and polishing as raw materials of the present invention comprises the following steps:

[0045] a. Extraction of fuel diesel

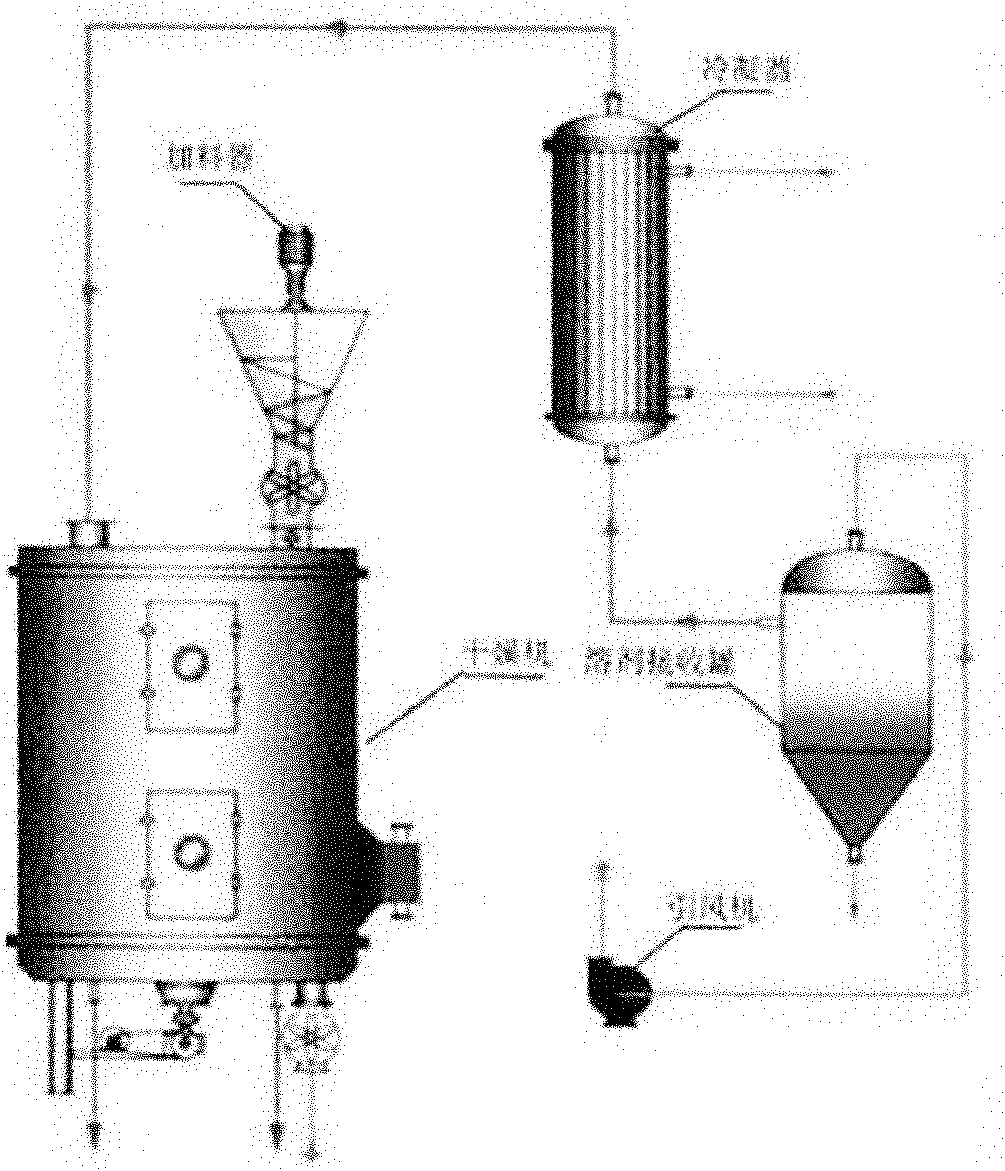

[0046] ①. Vacuum evaporation and condensation

[0047] Put the waste oil sand into the disc continuous dryer, heat it, evaporate it under the pressure of -0.02Mpa~-0.08Mpa, collect the fuel oil vapor fraction with a temperature between 180~270℃, enter the condenser, and condense into liquid Fuel diesel, to be filtered;

[0048] ②. Filtration

[0049] Filtrate through an oil filter to obtain fuel diesel;

[0050] ③. Cooling

[0051] The waste sand after extracting the fuel diesel is cooled to room temperature and set aside;

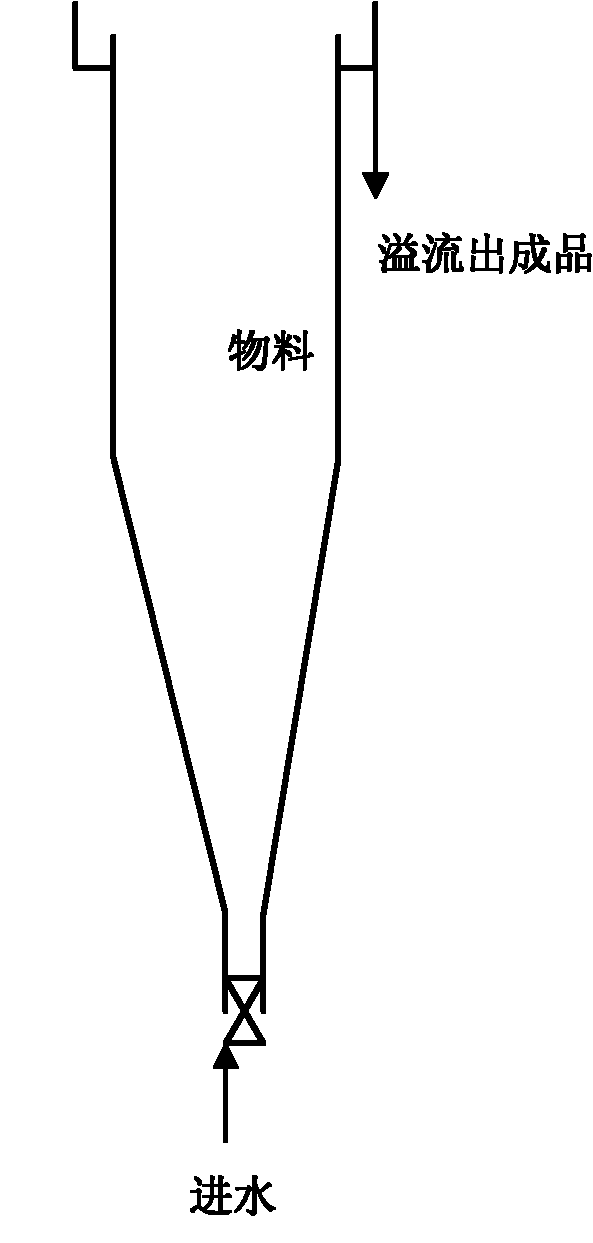

[0052] b. Extraction of silicon carbide powder

[0053] ①. Crushing and sieving

[0054] Pulverize the waste sand after extracting the fuel diesel in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com