Recycling and emission reduction method of gases in sludge aerobic treatment

A technology for aerobic treatment and sludge, applied in the fields of sludge treatment, biological sludge treatment, energy and wastewater treatment, etc., can solve the problem of increasing the investment and operation cost of aerobic treatment of sludge, increasing the cost of biological testing of bacteria and products, Affecting issues such as the safe application of sludge products, to achieve the effect of shortening the sludge treatment cycle, reducing investment and operating costs for odor treatment, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

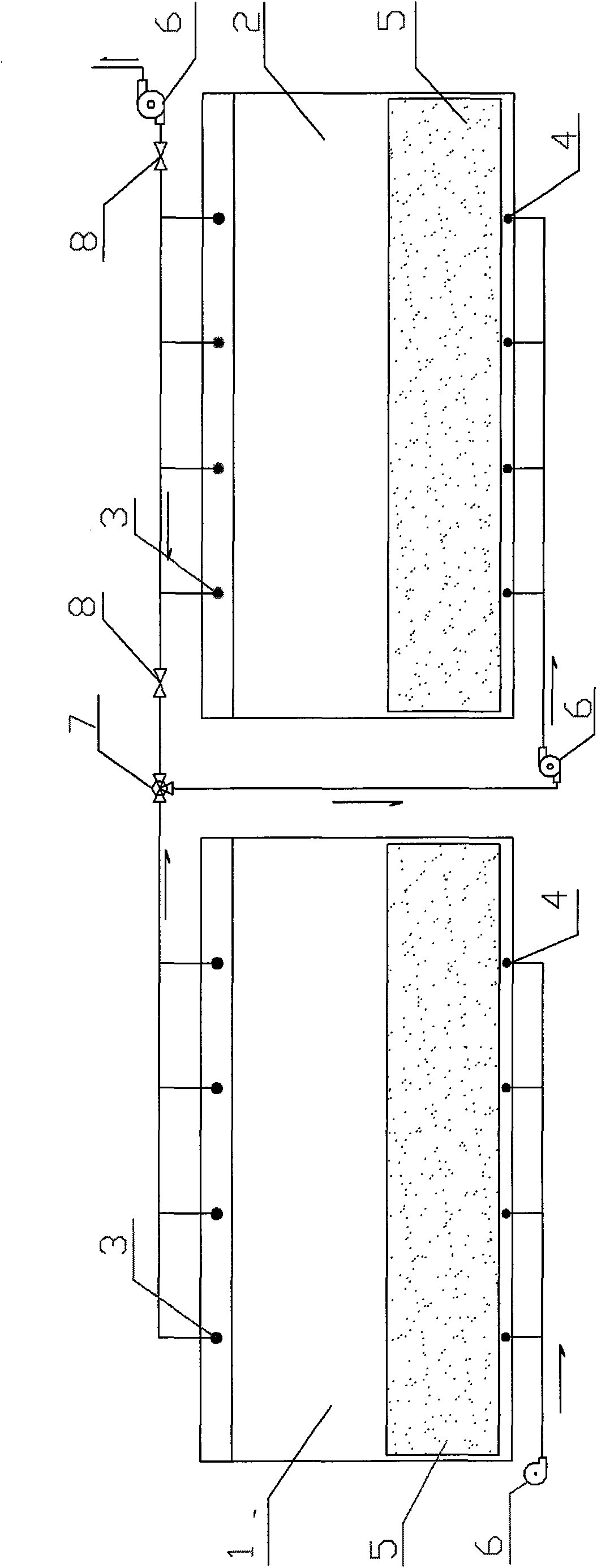

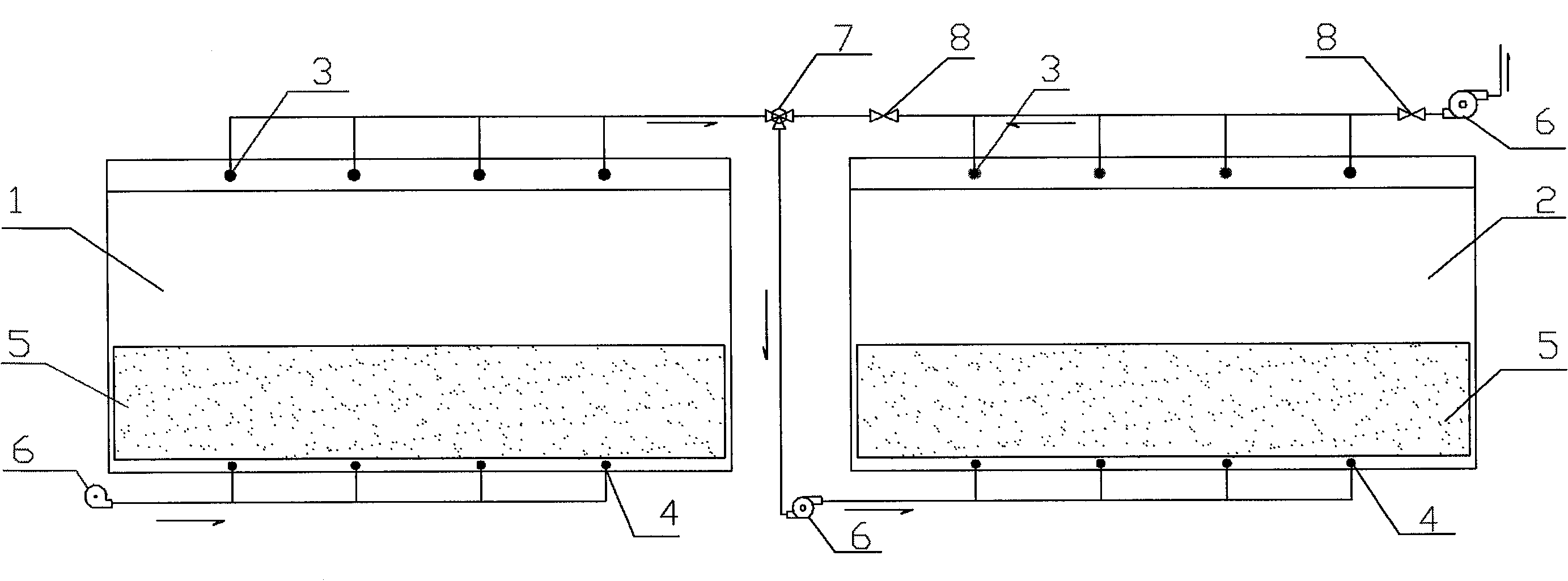

[0016] According to the characteristics of the relationship between the microbial activity and the temperature of the sludge pile during the static aerobic treatment of sludge, it can be generally divided into four stages: heating stage, high temperature stage, cooling stage and decomposing stage. The heating stage is mainly concentrated in the initial 1 to 3 days of sludge aerobic treatment. The main active microorganisms are mesophilic and aerobic bacteria and fungi, which use the most easily decomposed soluble substances (such as starch, sugar, etc.) to rapidly proliferate and release heat. The temperature of the stack is continuously increased from normal temperature to 45-50 degrees. High temperature stage: mainly focus on 3 to 8 days of aerobic treatment of sludge, and its temperature range is between 50 degrees and 70 degrees. There are many kinds of microorganisms, and the decomposition objects change with the dominance of the microbial population, and the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com