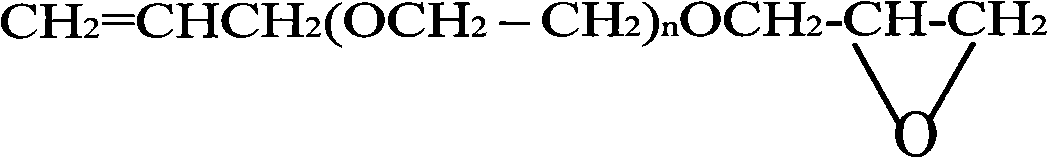

Preparation method of glycidol ether base allyl alcohol polyoxyethylene ether

A technology of allyl alcohol polyoxyethylene ether and allyl alcohol polyoxyethylene ether, which is applied in the field of preparation of glycidyl ether-based allyl alcohol polyoxyethylene ether, can solve the problem of low reaction efficiency, many by-products, and low yield Low-level problems, to achieve the effect of high reaction efficiency, less side reactions, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

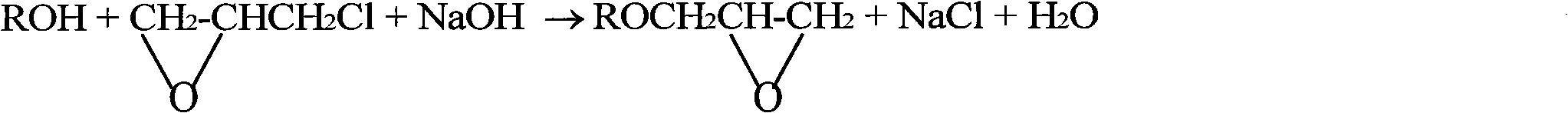

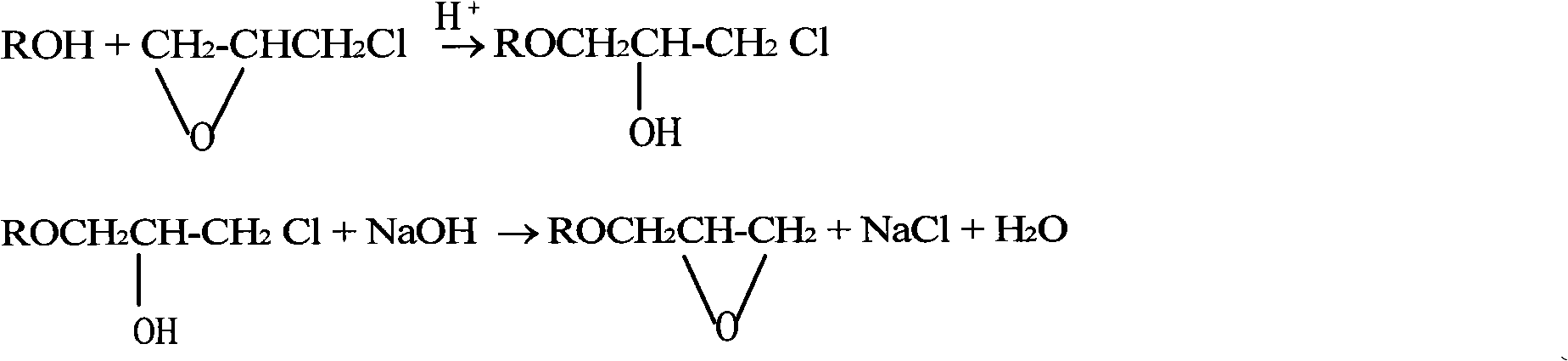

Method used

Image

Examples

Embodiment 1

[0044] Add 1,000 g of allyl alcohol polyoxyethylene ether (molecular weight: 410, n=8), 178 g of solid potassium hydroxide, and 250 g of benzene into a 2L reactor, and stir. Raise the temperature to 80-90°C, remove the water through the water separator, reflux the benzene, and react for 2 hours. After the reaction, the benzene is recovered by distillation under reduced pressure. Cool down to 40-50°C, slowly add 294g of epichlorohydrin dropwise, and react for 3 hours after the dropwise addition. The unreacted epichlorohydrin is removed under reduced pressure, and the glycidyl ether-based allyl alcohol polyoxyethylene ether product is obtained after filtering to remove solid impurities.

Embodiment 2

[0046]Add 1,000 g of allyl polyoxyethylene ether (molecular weight: 1158, n=25), 78 g of solid sodium hydroxide, and 100 g of toluene into a 2L reactor, and stir. Raise the temperature to 100-110°C, remove the water through the water separator, reflux the benzene, and react for 3 hours. After the reaction is completed, the benzene is recovered by distillation under reduced pressure. Cool down to 60-70°C, slowly add 128g of epichlorohydrin dropwise, and react for 5 hours after the dropwise addition. The unreacted epichlorohydrin is removed under reduced pressure, and the glycidyl ether-based allyl alcohol polyoxyethylene ether product is obtained after filtering to remove solid impurities.

Embodiment 3

[0048] Add 1000 g of allyl polyoxyethylene ether (molecular weight 2038, n=45), 55 g of a mixture of solid potassium hydroxide and solid sodium hydroxide, and 50 g of a mixture of benzene and toluene into a 2L reactor, and stir. Raise the temperature to 120-130°C, remove the water through the water separator, reflux the benzene, and react for 5 hours. After the reaction is completed, the benzene is recovered by distillation under reduced pressure. Cool down to 80-90°C, slowly add 91 g of epichlorohydrin dropwise, and react for 8 hours after the dropwise addition. The unreacted epichlorohydrin is removed under reduced pressure, and the glycidyl ether-based allyl alcohol polyoxyethylene ether product is obtained after filtering to remove solid impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com