InP based long wavelength 2-3mum quasi-quantum dot laser structure

A laser and long-wavelength technology, applied in lasers, phonon exciters, laser components, etc., can solve problems such as unsatisfactory performance of QD lasers, limited number of growth layers, and poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

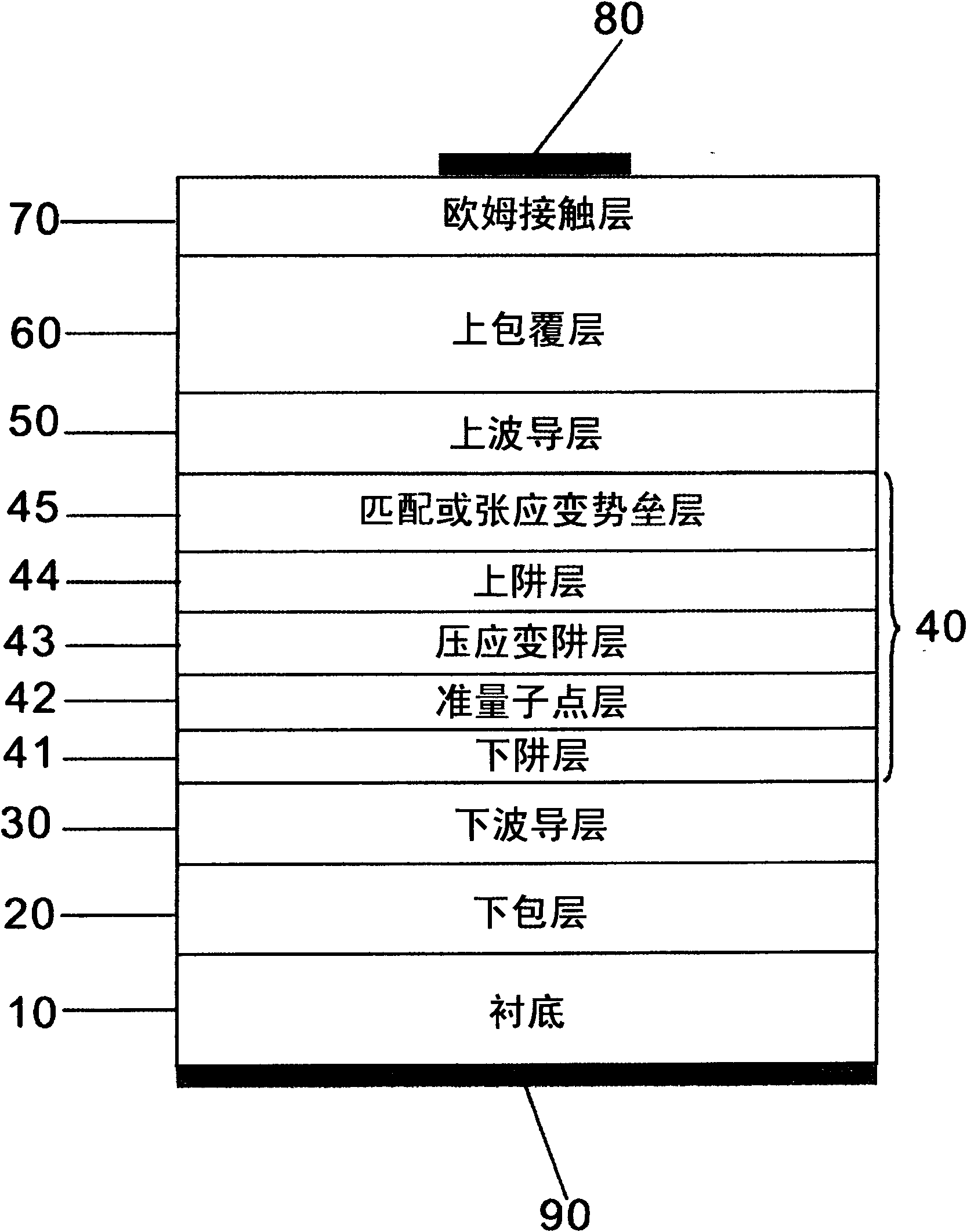

[0031] See figure 1 As shown, the present invention provides an InP-based long wavelength 2-3μm quasi-quantum dot laser structure, including:

[0032] A substrate 10, the substrate 10 is a heavily doped InP(001) substrate, the doping element is Si, and the doping concentration is (0.5-7)×10 18 / cm 3 ;

[0033] The lower cladding layer 20, which is made on the substrate 10, is an InP lower cladding layer, and its lattice constant matches the lattice constant of the substrate 10. The so-called lattice constant matching refers to the lattice constant of the epitaxial material and The lattice constant of InP(001) substrate is the same, and there is no stress between the two during epitaxial growth. The growth thickness of the lower cladding layer 20 is 0-3000nm, which is n-type doped, the doping element is Si, and the doping concentration is (0.1-5)×10 18 / cm 3 , It is doped to better provide electrons to the active area. The lower cladding layer 20 also functions as a buffer layer. At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com