Electromagnetic shielding plate and manufacturing method thereof

A production method and electromagnetic shielding technology, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor mechanical properties, bending resistance, secondary environmental pollution, complex structure, etc., and achieve low cost, simple and feasible method, and easy implementation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

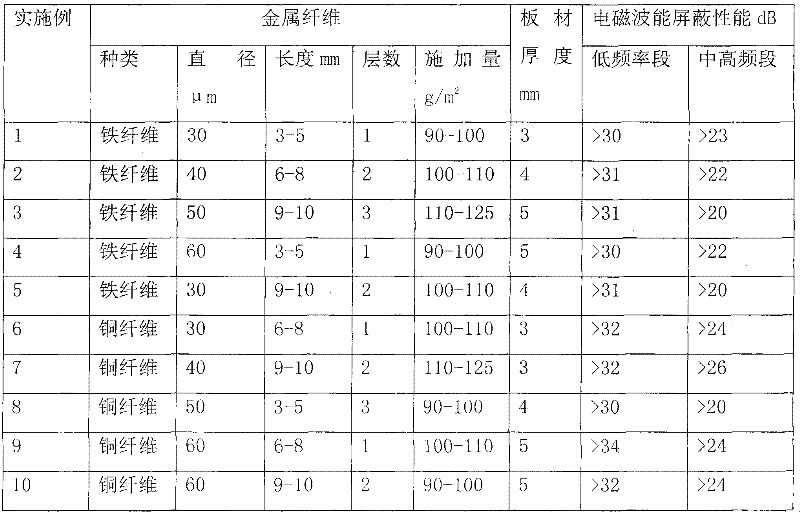

[0027] Embodiment 1-10: plate (electromagnetic shielding plate)

[0028] Plate (electromagnetic shielding plate) production steps:

[0029] a. Preparation of paper / plastic / aluminum fiber mixture: Tetra Pak packaging waste is cut, crushed and shredded to obtain a paper / plastic / aluminum fiber mixture. The particle size of the paper / plastic / aluminum fiber mixture is: below 40 mesh (3.58%), 40-50 mesh (35.70%), 50-60 mesh (25.00%), 60-70 mesh (3.60%), 70- 80 mesh (32.12%). The moisture content of the paper / plastic / aluminum fiber mixture is 3-4%.

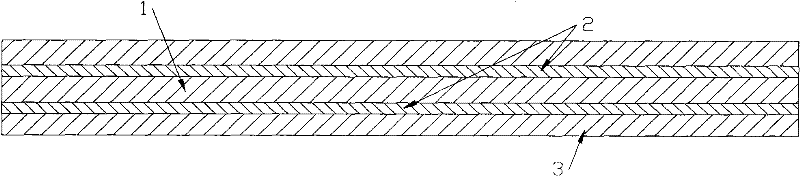

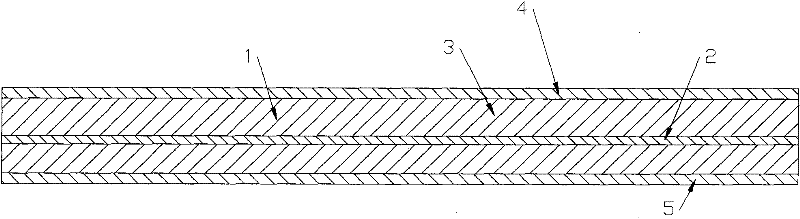

[0030] b. Pavement: see figure 1 , with paper / plastic / aluminum fiber mixture 1 as the base material, metal fibers of different types, different diameters, and different lengths listed in Table 1 as filling materials, paved into compacts; paving metal fiber layers in the compacts Layers of 2 ( figure 1 Two layers are shown in ) and the amount of metal fiber added per square meter of compact is listed in Table 1. The applied amount o...

Embodiment 11

[0036] Example 11: Tetra Pak waste / poplar veneer electromagnetic shielding composite board (electromagnetic shielding board)

[0037] Production process steps of Tetra Pak waste / poplar veneer electromagnetic shielding composite board.

[0038] 1. Preparation of paper / plastic / aluminum fiber mixture, the process flow is divided into:

[0039] Tetra Pak packaging waste is cut, shredded and pulverized to obtain a paper / plastic / aluminum fiber mixture. The particle size of the paper / plastic / aluminum fiber mixture is: below 40 mesh (3.58%), 40-50 mesh (35.70%), 50-60 mesh (25.00%), 60-70 mesh (3.60%), 70- 80 mesh (32.12%). The moisture content of the paper / plastic / aluminum fiber mixture is 3%.

[0040] 2. Preparation of wood veneer (poplar veneer)

[0041] 1) For veneer manufacturing, the density is 0.40g / cm 3 The fast-growing poplar logs are cut off, peeled and peeled to make poplar veneer strips with a rotary cutting machine, and the thickness is controlled at 0.8±0.02mm;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com