Closed circulating seawater prawn pond culture system

A culture system and closed cycle technology, applied in the field of shrimp farming, can solve the problems of inability to remove residues, environmental pollution, increase ammonia nitrogen and suspended solids concentration, etc., to reduce infectious diseases and virus pollution incidents, reduce dependence, and achieve The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

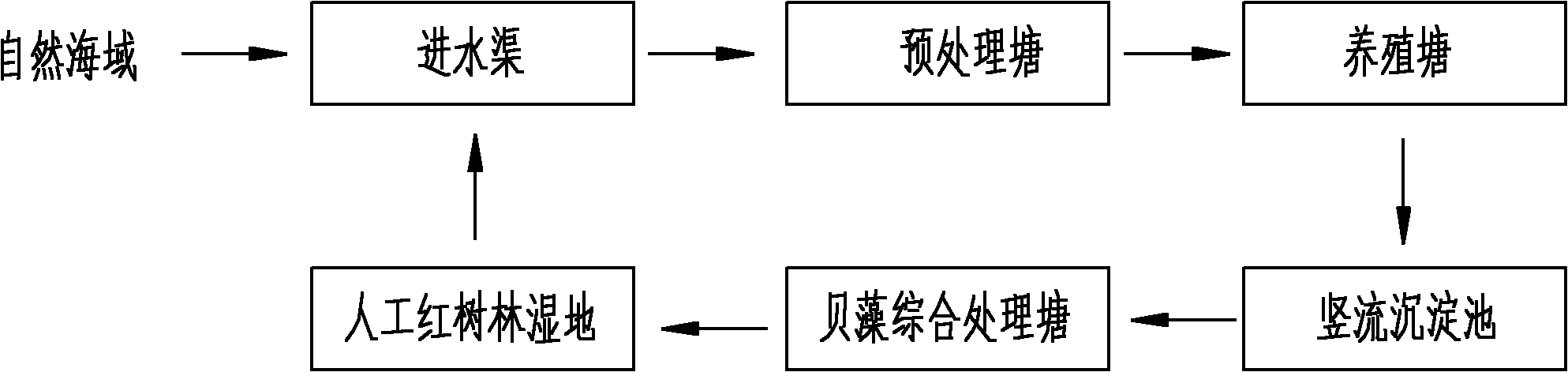

[0036] A closed circulation seawater prawn pond culture system is characterized in that: the culture system includes a culture pond, a vertical flow sedimentation pond, a shellfish comprehensive treatment pond and an artificial mangrove wetland in sequence;

[0037] The culture pond is square or circular, with a single pond area of 0.4-0.6m 2 , consisting of 2-3 shrimp ponds, the depth of the pond is 2-2.2m, and the water depth in the pond is 1.6-1.8m;

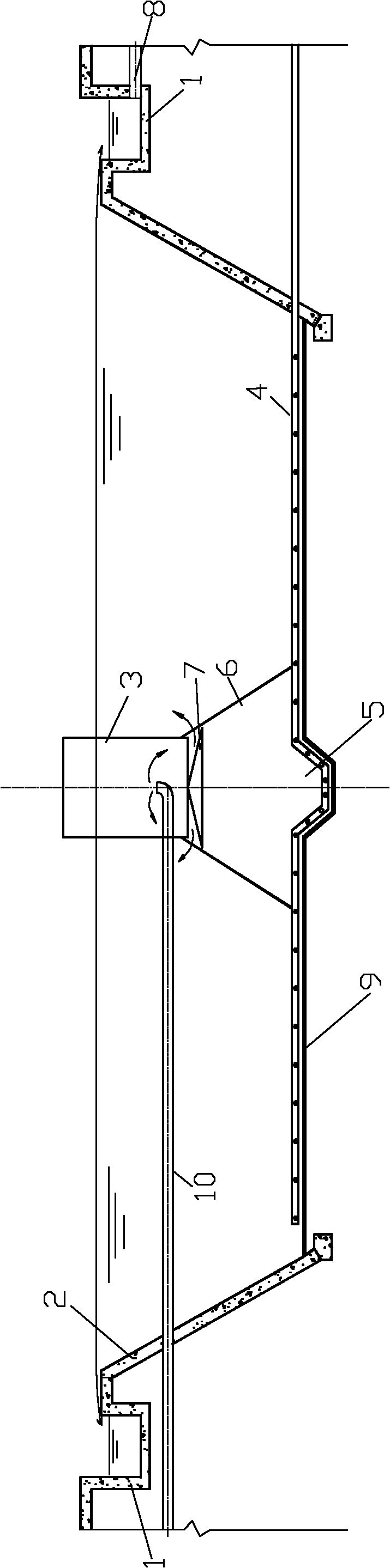

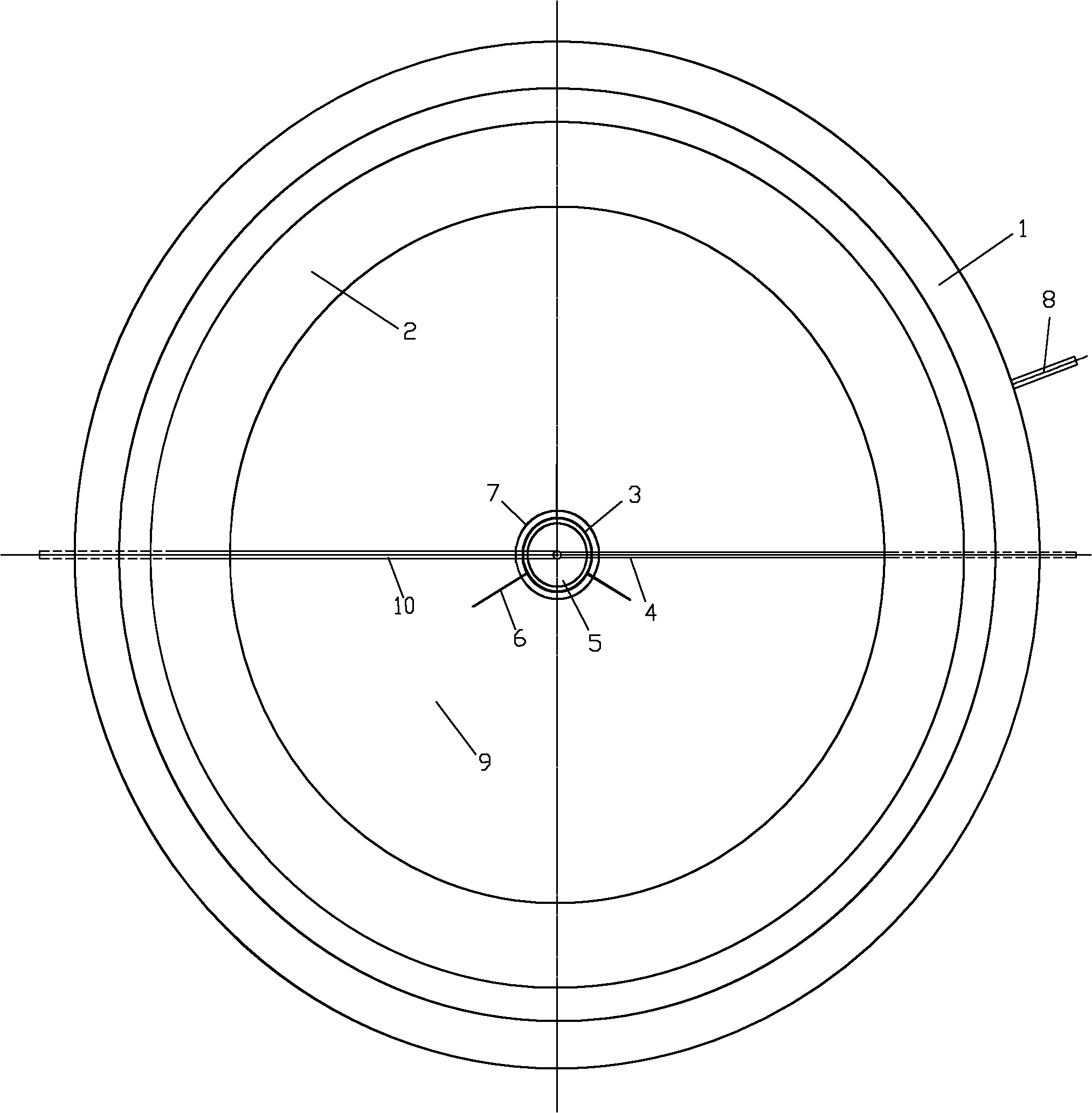

[0038] The vertical flow sedimentation pond is a circular or square cut fillet pool type, the peripheral inner wall 2 is inclined upward, the upper edge is provided with an annular water outlet 1, an outlet pipe 8, and a concave mud collection pit 5 is arranged at the bottom of the center, connected by a mud discharge pipe 4 To the outside of the pool, a central pipe 3 with upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com