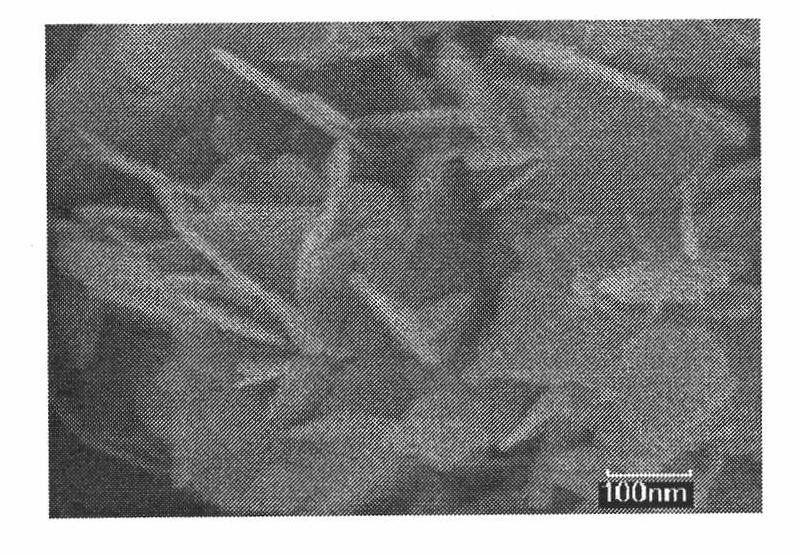

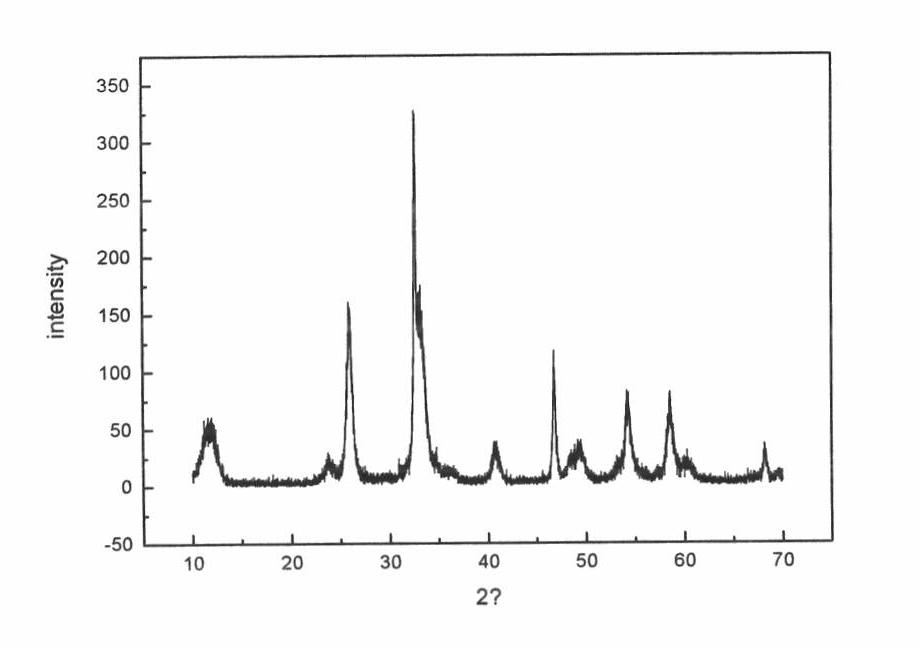

Preparation and application methods of BiOBr/BiOCl compound photocatalyst

A photocatalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as shortage, wide band gap, polluted energy, etc., achieve low cost, simple preparation method, good physical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

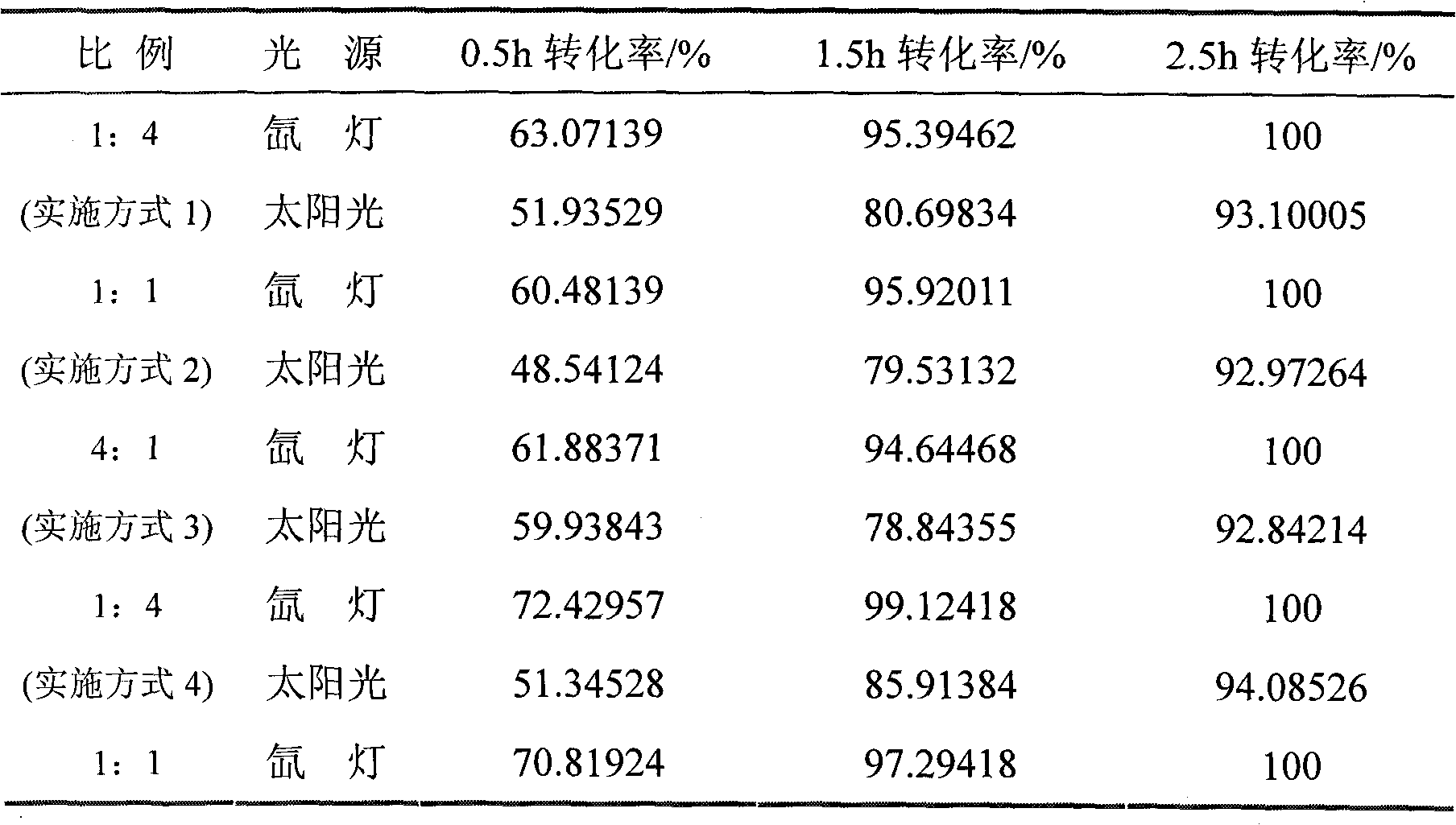

[0020] Weigh 0.315g BiCl 3 and 1.795gBiBr 3 Put together in 0.1mol·L -1 Dilute hydrochloric acid 100mL, then add 0.05mol sodium dodecylbenzenesulfonate dispersant, make BiCl 3 and BiBr 3 Fully dissolve and keep the solution in a transparent state, then slowly add 2.0mol / L Na 2 CO 3 Solution 10mL, the pH value is controlled at 8, followed by stirring for 1 hour to obtain a suspension solution, and finally, the filter cake is washed with distilled water, and then the filter cake is dried at 40°C to obtain BiOCl with a molar ratio of 1:4 / BiOBr composite photocatalyst.

[0021] The obtained photocatalyst is used for oxidation treatment of methyl orange aqueous solution. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, 0.8 g / L of photocatalyst, and air is blown from the bottom of the reactor. Samples were taken and analyzed at regular intervals, and the conversion rate of methyl orange was measured by UV-Vis spec...

Embodiment approach 2

[0023] Weigh 0.788g BiCl 3 and 1.122gBiBr 3 Put together in 0.1mol·L -1 Dilute hydrochloric acid 100mL, then add 0.06mol dodecyl ammonium chloride dispersant, make BiCl 3 and BiBr 3 Fully dissolve and keep the solution in a transparent state, slowly add 2.0mol / L Na 2 CO 3 Solution 12mL, the pH value is controlled at 9, followed by stirring for 1.1 hours to obtain a suspension solution, and finally, the filter cake is washed with distilled water, and then the filter cake is dried at 50°C to obtain BiOCl with a molar ratio of 1:1 / BiOBr composite photocatalyst.

[0024] The obtained photocatalyst is used for oxidation treatment of humic acid aqueous solution. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L humic acid aqueous solution, 1.0 g / L of photocatalyst, and air is blown from the bottom of the reactor. Samples were taken and analyzed at regular intervals, and the conversion rate of humic acid was measured by UV-Vis spectrophotometry. T...

Embodiment approach 3

[0026] Weigh 1.261g BiCl 3 and 0.449gBiBr 3 Put together in 0.1mol·L -1 Dilute hydrochloric acid 100mL, then add 0.08mol sodium dodecylbenzenesulfonate dispersant, make BiCl 3 and BiBr 3 Fully dissolve and keep the solution in a transparent state, add 0.1mol L under magnetic stirring -1 5mL of urea solution and slowly add 2.0mol / LNa 2 CO 3 Solution 15mL, the pH value is controlled at 11, followed by stirring for 1.2 hours to obtain a suspension solution, and finally, the filter cake is washed with distilled water, and then the filter cake is dried at 60°C to obtain BiOCl with a molar ratio of 4:1 / BiOBr composite photocatalyst.

[0027] The obtained photocatalyst is used for oxidation treatment of phenol aqueous solution. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L phenol aqueous solution, 1.2 g / L of photocatalyst, and air is blown from the bottom of the reactor. Samples were taken and analyzed at regular intervals, and the conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com