Tobacco wastewater sludge activation and recycling method

A waste water sludge and tobacco technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of comprehensive utilization of urban solid waste that have not been seen, and achieve Practical alkaloid activity, easy storage, and obvious effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

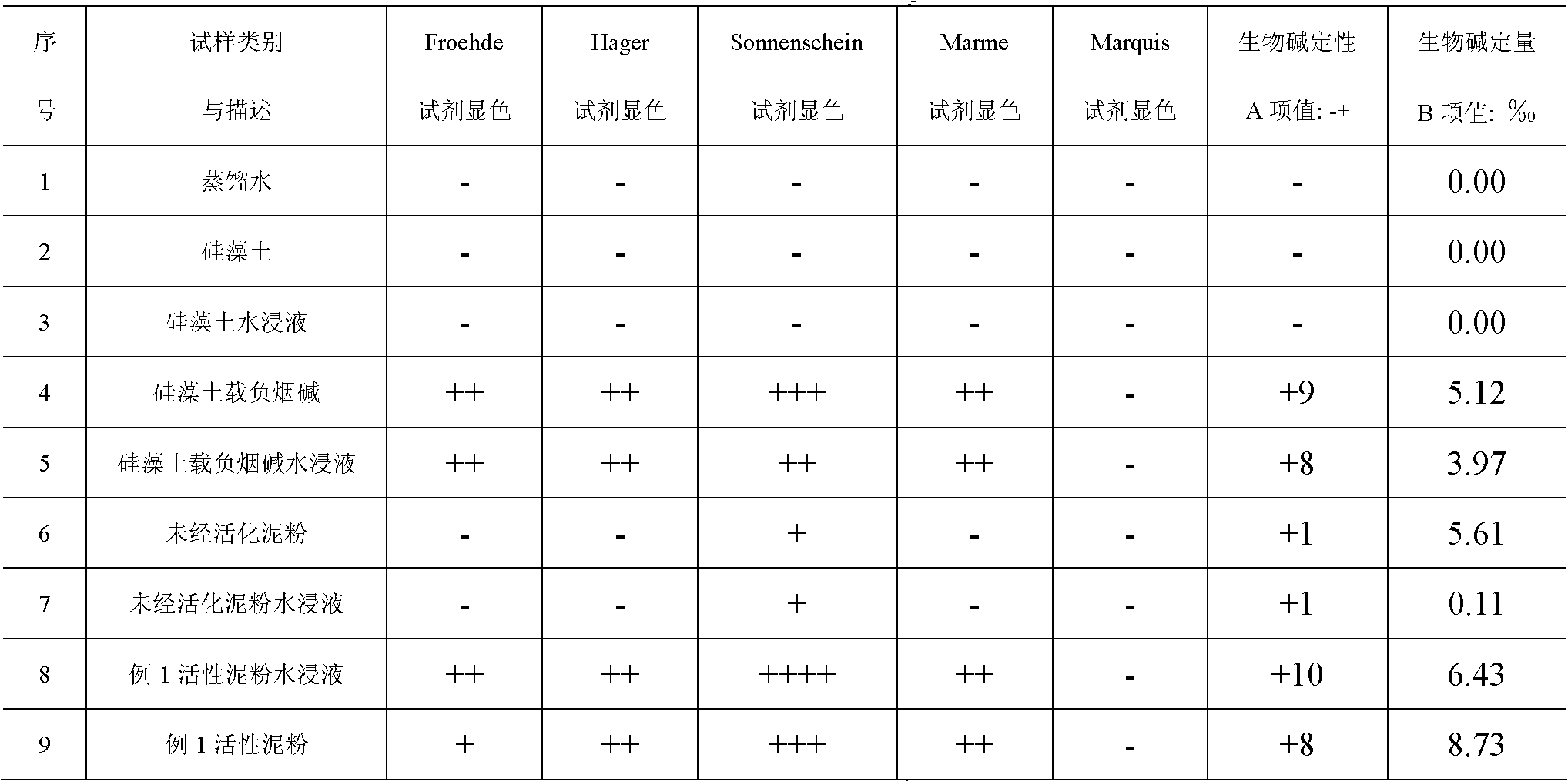

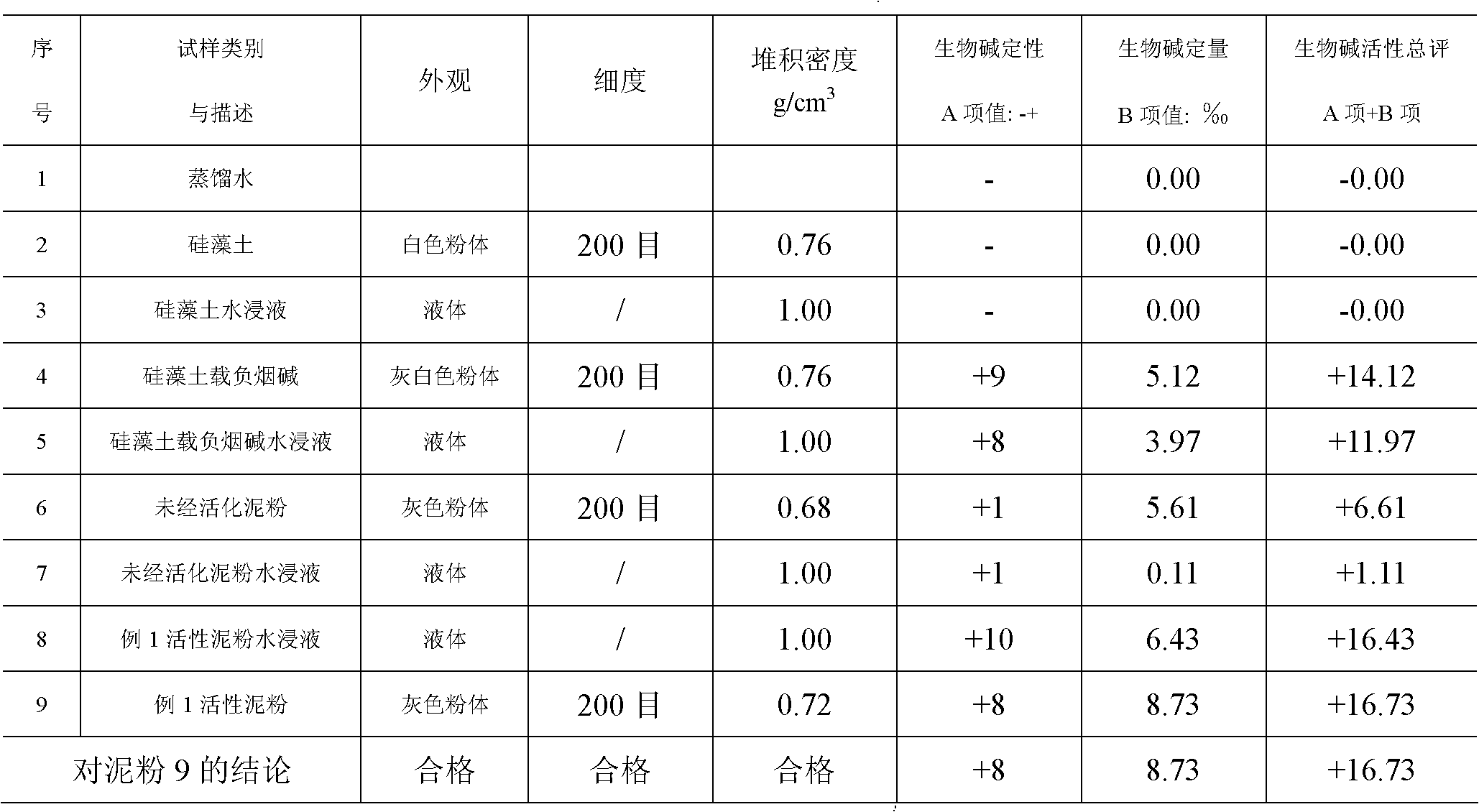

[0054] Wastewater from the homogenization tank of the sewage treatment station of the cigarette production plant is processed through the whole process to obtain mud powder with certain alkaloid activity. Five indicators were used to qualitatively detect the apparent alkaloid free (A item value) of the powder, and qualitatively evaluate the apparent alkaloid activity of the powder. "Water immersion-ultraviolet spectrophotometry" was used to quantitatively detect the release of alkaloids (B item value) when the powder was immersed in water, so as to evaluate the alkaloid releasability of the powder.

[0055] Take 50kg of comprehensive wastewater from Wuhan Tanyaxiang Technology Development Co., Ltd., and the wastewater will be sampled by the Environmental Monitoring Station of Hanyang District, Wuhan City, and the active mud powder will be prepared in the laboratory. The specific operation is as follows:

[0056] First, according to the "solid-liquid enrichment and separation ...

Embodiment 2

[0065] Take 5kg of sludge from the sludge concentration tank of the sewage treatment station of Hubei Xinye Tobacco Flake Development Co., Ltd., and the sludge is sent by Wuhan Green Environmental Protection Facility Operation Co., Ltd. for sludge pretreatment and activated sludge powder preparation in the laboratory. The detection of the mud powder is carried out in the same manner as in Example 1, and 5 kinds of indicators are used to qualitatively detect the apparent alkaloid free (A item value) situation of the powder, and qualitatively evaluate the apparent alkaloid activity of the powder. "Water immersion-ultraviolet spectrophotometry" was used to quantitatively detect the release of alkaloids (B item value) when the powder was immersed in water, so as to evaluate the alkaloid releasability of the powder.

[0066] For the 5kg sludge in Example 2, the whole process of preparation is as follows: 5kg sludge → adding pretreatment agent → coagulation and concentration → sludge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com