Hyaluronic acid-sodium alginate composite hydrogel and preparation method thereof

A composite hydrogel and sodium alginate technology, applied in the field of hyaluronic acid-sodium alginate composite hydrogel and its preparation, to achieve improved mechanical properties and texture characteristics, improved physical and chemical properties, and the ability to resist enzymatic degradation Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1. Preparation of hyaluronic acid-sodium alginate hydrogel and verification of its physical and chemical properties

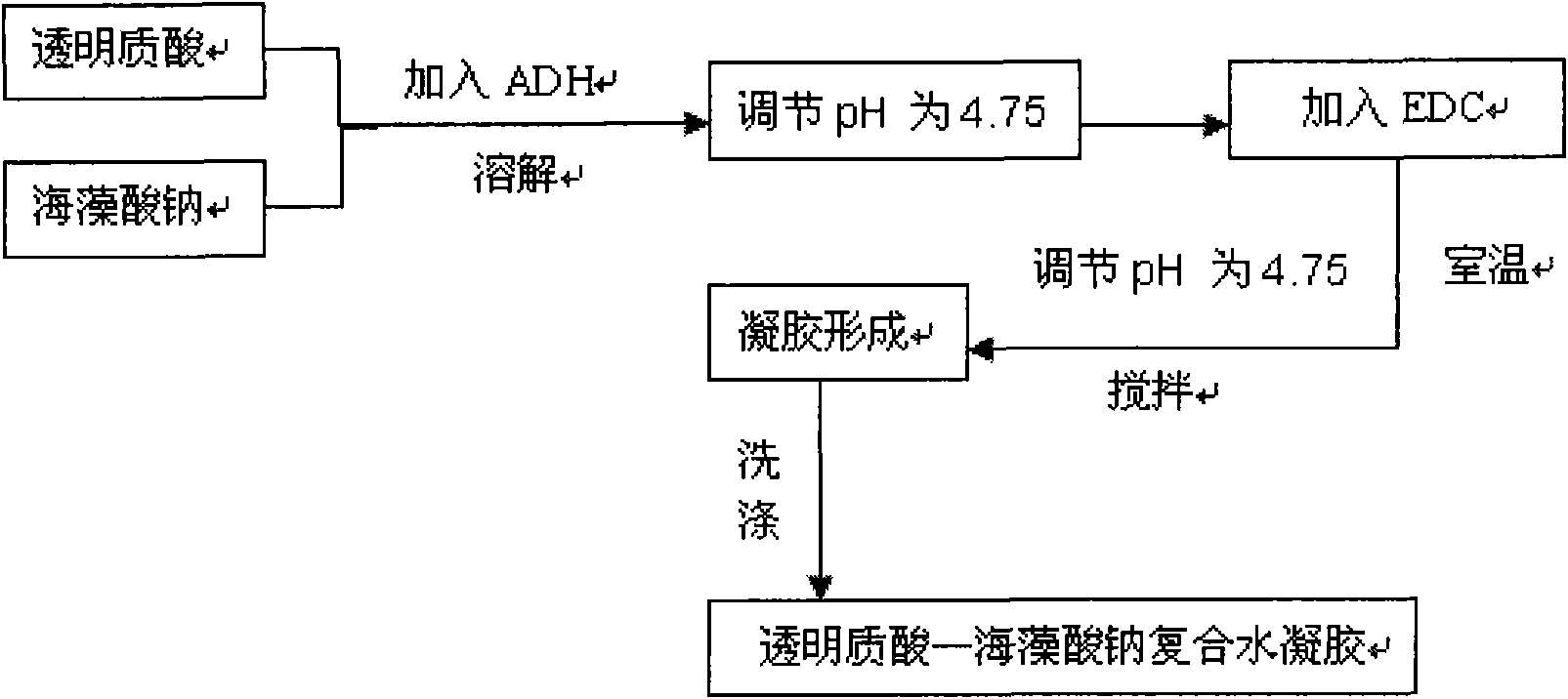

[0022] according to figure 1 The shown process flow chart prepares hyaluronic acid-sodium alginate hydrogel, and the specific steps are as follows:

[0023] ①Polysaccharide dissolution: molecular weight 1.5×10 6 Da's hyaluronic acid (Shandong Freda Biochemical Co., Ltd.) and sodium alginate (a particle size of 200 mesh, 10 mg / ml aqueous solution, the viscosity at 25 ° C is 205 mPa s, Qingdao Jingyan Biotechnology Co., Ltd. company) was dissolved in water at a ratio (mass ratio) of 1:2 so that its total concentration was 1.0% (g / 100ml) to obtain solution 1.

[0024] ②Add a cross-linking agent and adjust the pH of the solution: After the polysaccharide in step ① is completely dissolved, add the cross-linking agent ADH (Beijing Jinyuan Chemical Group Co., Ltd.) into the solution 1 at a ratio of 0.52g:100ml, mix uniform. The pH of the above mixed...

Embodiment 2

[0039] Example 2. Preparation of hyaluronic acid-sodium alginate hydrogel and verification of its physical and chemical properties

[0040] according to figure 1 The shown process flow chart prepares hyaluronic acid-sodium alginate hydrogel, and the specific steps are as follows:

[0041] ① Polysaccharide dissolution: molecular weight 5.0×10 5 Da's hyaluronic acid (Shandong Freda Biochemical Co., Ltd.) and sodium alginate (a particle size of 50 mesh, 10 mg / ml aqueous solution, the viscosity at 25 ° C is 100 mPa s, Qingdao Jingyan Biotechnology Co., Ltd. company) was dissolved in water at a ratio (mass ratio) of 1:4 so that its total concentration was 0.5% (g / 100ml) to obtain solution 1.

[0042] ②Add a cross-linking agent and adjust the pH of the solution: After the polysaccharide in step ① is completely dissolved, add the cross-linking agent ADH (Beijing Jinyuan Chemical Group Co., Ltd.) into the solution 1 at a ratio of 0.1g:100ml, mix uniform. The pH of the above mixed ...

Embodiment 3

[0054] Example 3. Preparation of hyaluronic acid-sodium alginate hydrogel and verification of its physical and chemical properties

[0055] according to figure 1 The shown process flow chart prepares hyaluronic acid-sodium alginate hydrogel, and the specific steps are as follows:

[0056] ① Polysaccharide dissolution: molecular weight 2.1×10 6 Da's hyaluronic acid (Shandong Freda Biochemical Co., Ltd.) and sodium alginate (a particle size of 300 mesh, 10mg / ml aqueous solution, the viscosity at 25 ° C is 300mPa s, Qingdao Jingyan Biotechnology Co., Ltd. company) was dissolved in water at a ratio (mass ratio) of 4:1 so that its total concentration was 1.5% (g / 100ml) to obtain solution 1.

[0057] ②Add a cross-linking agent and adjust the pH of the solution: After the polysaccharide in step ① is completely dissolved, add the cross-linking agent ADH (Beijing Jinyuan Chemical Group Co., Ltd.) into the solution 1 at a ratio of 1.0g:100ml, mix uniform. The pH of the above mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com