Material special for corrugated pipe for high-density polyethylene prestressed concrete and production method thereof

A high-density polyethylene, prestressed technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of ring stiffness bellows dimensional stability and poor weight gain effect, and achieve enhanced overall mechanical properties , Extensive supply and low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

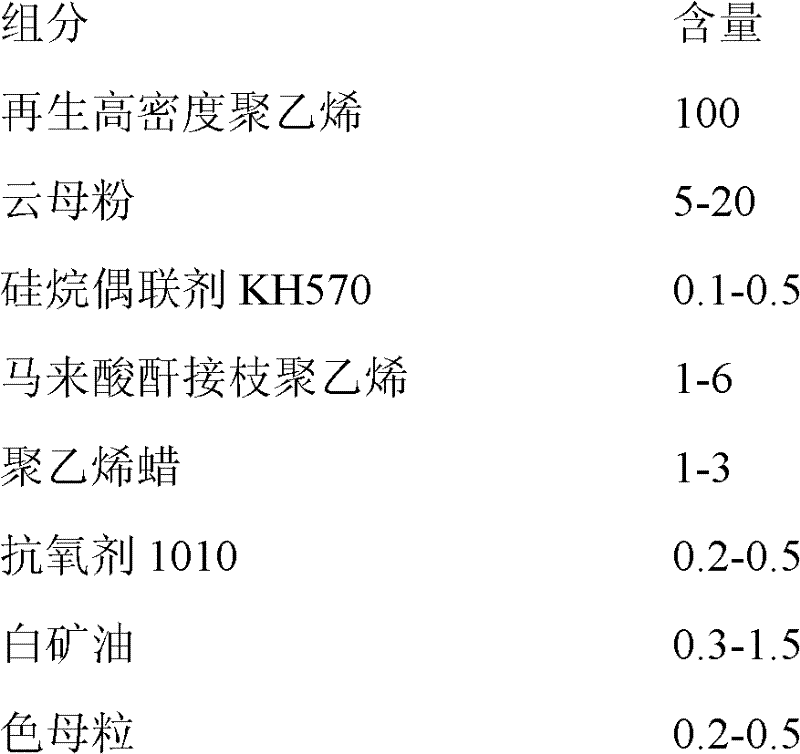

Embodiment 1

[0037] First, add 8kg of mica powder (500 mesh), 0.1kg of silane coupling agent KH570 (Foshan Daoning Chemical Co., Ltd.), and 1kg of PE wax into a high-speed mixer, and blend at a speed of 1200r / min while heating Raise the temperature to 120°C, stir at a high speed of 1200r / min for 3 minutes, then add 100kg of recycled high-density polyethylene, 1kg of maleic anhydride grafted polyethylene (Foshan Baichen Polymer Material Co., Ltd.), white mineral oil (Maoming Petrochemical) 0.5kg, antioxidant 1010 (Taiwan Nanya Plastic Industry Co., Ltd.) 0.1kg, color masterbatch 0.2kg, continue mixing for 5 minutes at a temperature of 120°C and a rotating speed of 1200r / min, and then transfer to 180r Mix at a low speed of 1 / min, and discharge at 45°C. Finally, the mixed material is transferred to a twin-screw extruder for extruding and granulating to obtain a special material for corrugated pipes for high-density polyethylene prestressed concrete.

[0038] The density of ordinary high-dens...

Embodiment 2

[0040] First, 12kg of mica powder (400 mesh), 0.2kg of silane coupling agent KH570 (Foshan Daoning Chemical Co., Ltd.), and 2kg of PE wax are added to a high-speed mixer, and blended at a rotating speed of 1000r / min. High temperature to 130°C, then high-speed stirring at 1000r / min for 5 minutes, followed by adding 100kg of recycled high-density polyethylene, 3kg of maleic anhydride grafted polyethylene (Foshan Baichen Polymer Material Co., Ltd.), white mineral oil (Maoming Petrochemical) 1.0kg, antioxidant 1010 (Taiwan Nanya Plastic Industry Co., Ltd.) 0.3kg, color masterbatch 0.4kg, continue mixing for 2 minutes at a temperature of 130°C and a rotating speed of 1000r / min, and then transfer to 100r Mix at a low speed of 1 / min, and discharge at 45°C. Finally, the mixed material is transferred to a twin-screw extruder for extruding and granulating to obtain a special material for corrugated pipes for high-density polyethylene prestressed concrete.

[0041] The density of ordina...

Embodiment 3

[0043] First, add 20kg of mica powder (600 mesh), 0.4kg of silane coupling agent KH570 (Foshan Daoning Chemical Co., Ltd.), and 3kg of PE wax into a high-speed mixer, and blend at a speed of 800r / min while heating Raise the temperature to 100°C, stir at a high speed of 1200r / min for 2 minutes at this temperature, then add 100kg of regenerated high-density polyethylene and maleic anhydride grafted polyethylene (Foshan Baichen Polymer Material Co., Ltd.) 6kg, white mineral oil (Maoming Petrochemical) 1.5kg, antioxidant 1010 (Taiwan Nanya Plastic Industry Co., Ltd.) 0.5kg, color masterbatch 0.5kg, continue mixing for 5 minutes at a temperature of 100°C and a rotating speed of 1200r / min , and then turn to a low speed of 300r / min for mixing, and discharge at 45°C. Finally, the mixed material is transferred to a twin-screw extruder for extruding and granulating to obtain a special material for corrugated pipes for high-density polyethylene prestressed concrete.

[0044] The density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com