Method for increasing light dydrocarbon recovery rate of oil-field associated gas through shallow condensing recovery

A technology for associated gas and light hydrocarbons in oilfields, which is applied in the field of refrigeration recovery by expanders to achieve the effects of improving economic benefits and improving recovery rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

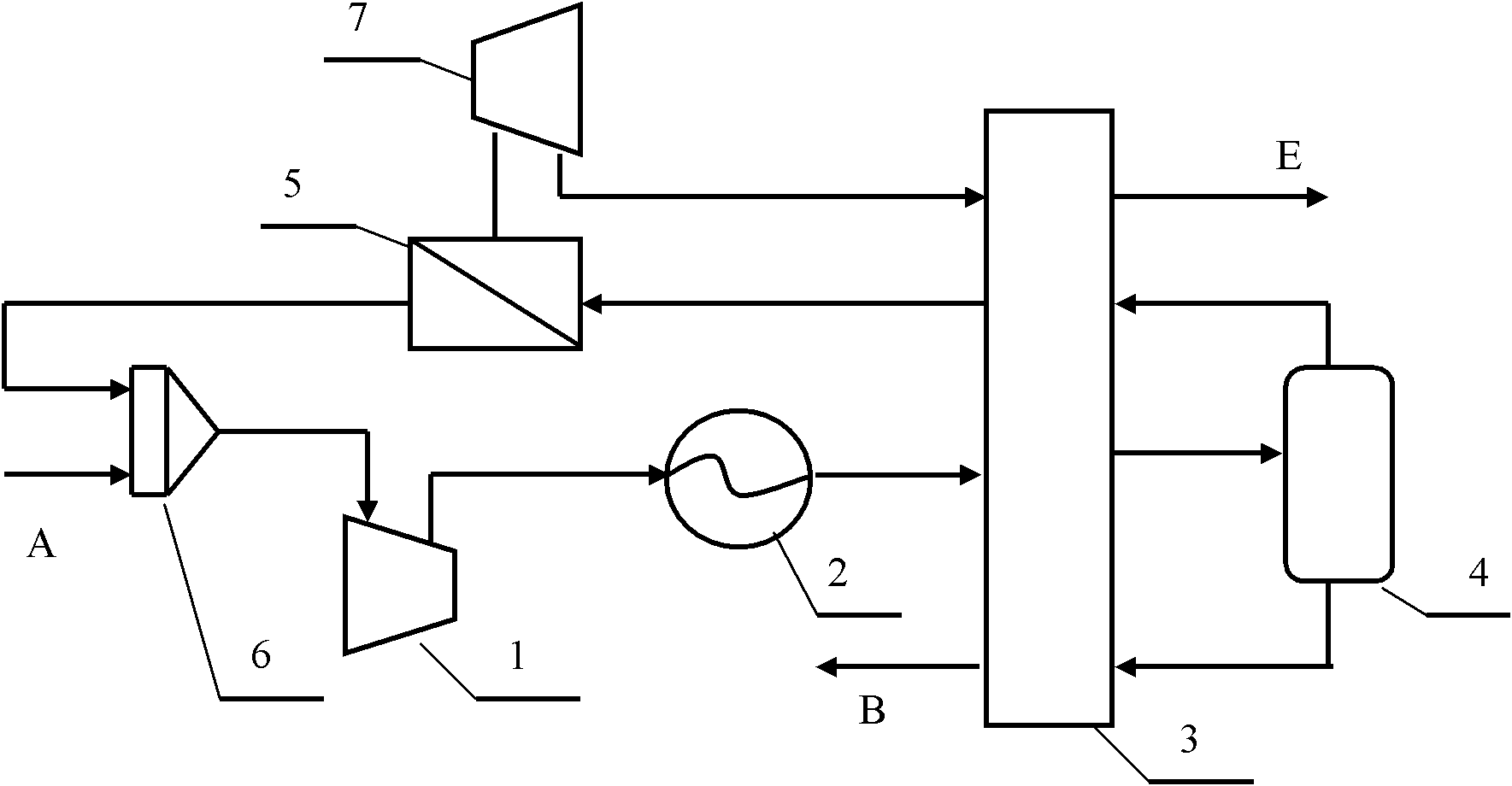

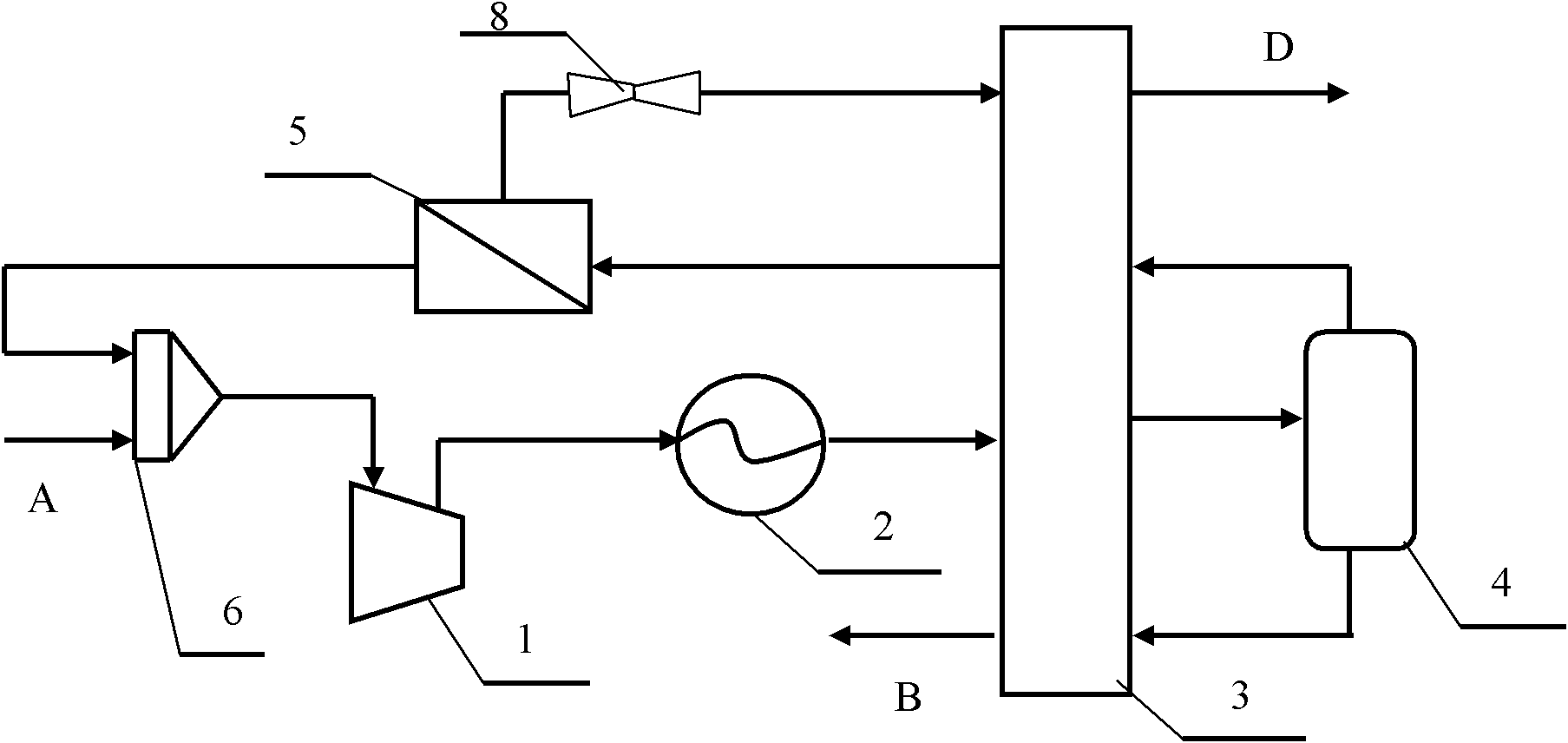

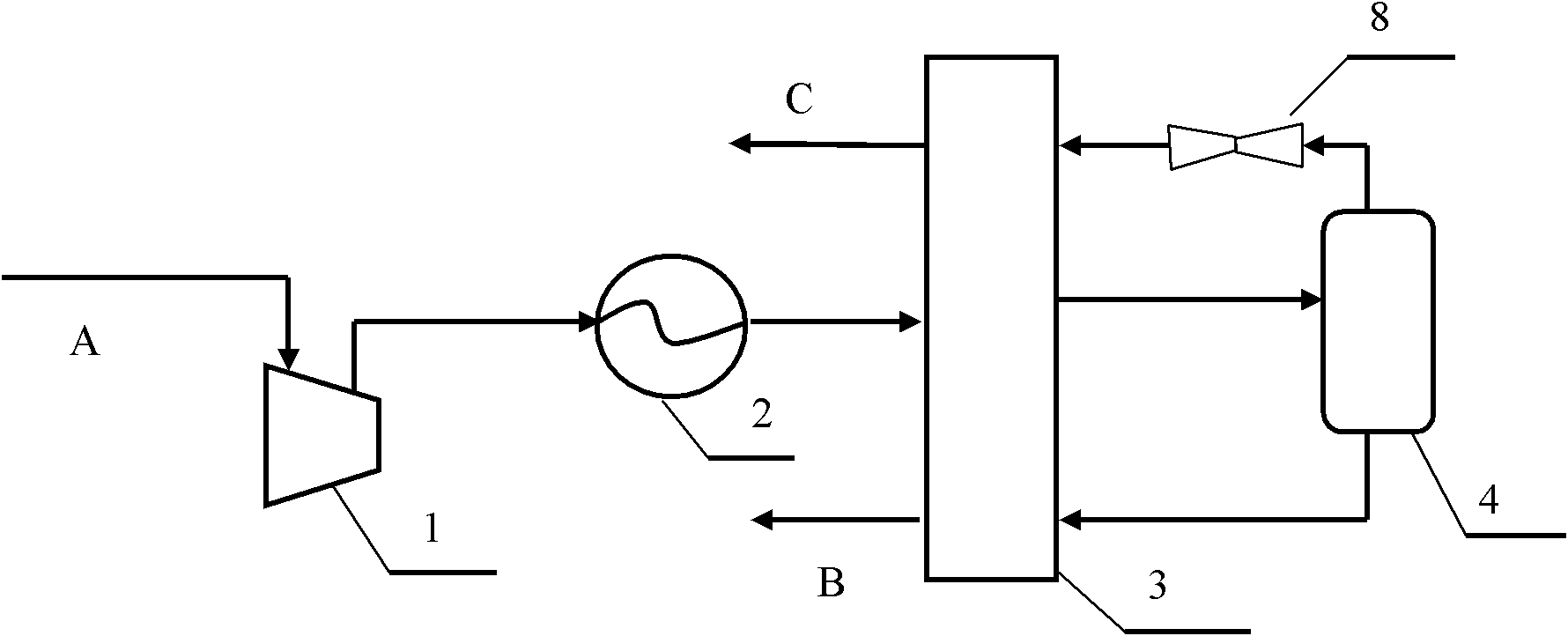

[0018] Example 1: 66000Nm 3 / d oilfield associated gas A(C 3 + : 13.75v%) enters the buffer tank 6 at 0.14MPa, the compressor 1 increases the pressure to 1.6MPa, and after the temperature of the cooler 2 drops to 40°C, the temperature is reduced to -25°C through the cold box 3 heat exchange. The condensed oilfield associated gas enters the gas-liquid separator 4 for gas-liquid separation to obtain a liquid-phase crude product, which is heat-exchanged to -12°C in the cold box 3 to obtain a liquid-phase product B, and subsequent processing can obtain high-purity C 3 + Components: The gas phase products of the gas-liquid separator are processed by different schemes, and then discharged into the gas pipeline network as dry gas after heat exchange in the cold box 3.

[0019] Scheme 1: Shallow cooling coupling membrane separation recovery of light hydrocarbons in oilfield associated gas and expansion machine recovery cooling capacity

[0020] figure 1 As shown, the gas-phase pr...

Embodiment 2

[0039] Example 2: 40000Nm 3 / d oilfield associated gas A(C 3 + : 12.56v%) enters the buffer tank 6 at 0.11MPa, the compressor 1 increases the pressure to 1.6MPa, and after the temperature of the cooler 2 drops to 40°C, the temperature is reduced to -25°C through the cold box 3 for heat exchange. The condensed oilfield associated gas enters the gas-liquid separator 4 for gas-liquid separation to obtain a liquid-phase crude product, which is heat-exchanged to -12°C in the cold box 3 to obtain a liquid-phase product B, and then high-purity C can be obtained through subsequent processing 3 + Components: The gas phase products of the gas-liquid separator are processed by different schemes, and then discharged into the gas pipeline network as dry gas after heat exchange in the cold box 3.

[0040] Scheme 1: Shallow cooling coupling membrane separation recovery of light hydrocarbons in oilfield associated gas and expansion machine recovery cooling capacity

[0041] figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com