Device for producing diesel from coal tar

A technology of coal tar and diesel oil, which is applied in the field of diesel catalytic production equipment, can solve the problems of incomplete oil refining and synthesis, inability to continuously mass-produce, limit the application and development of coal tar refined diesel technology, etc., and achieve accelerated oil refining speed, high production efficiency, The effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

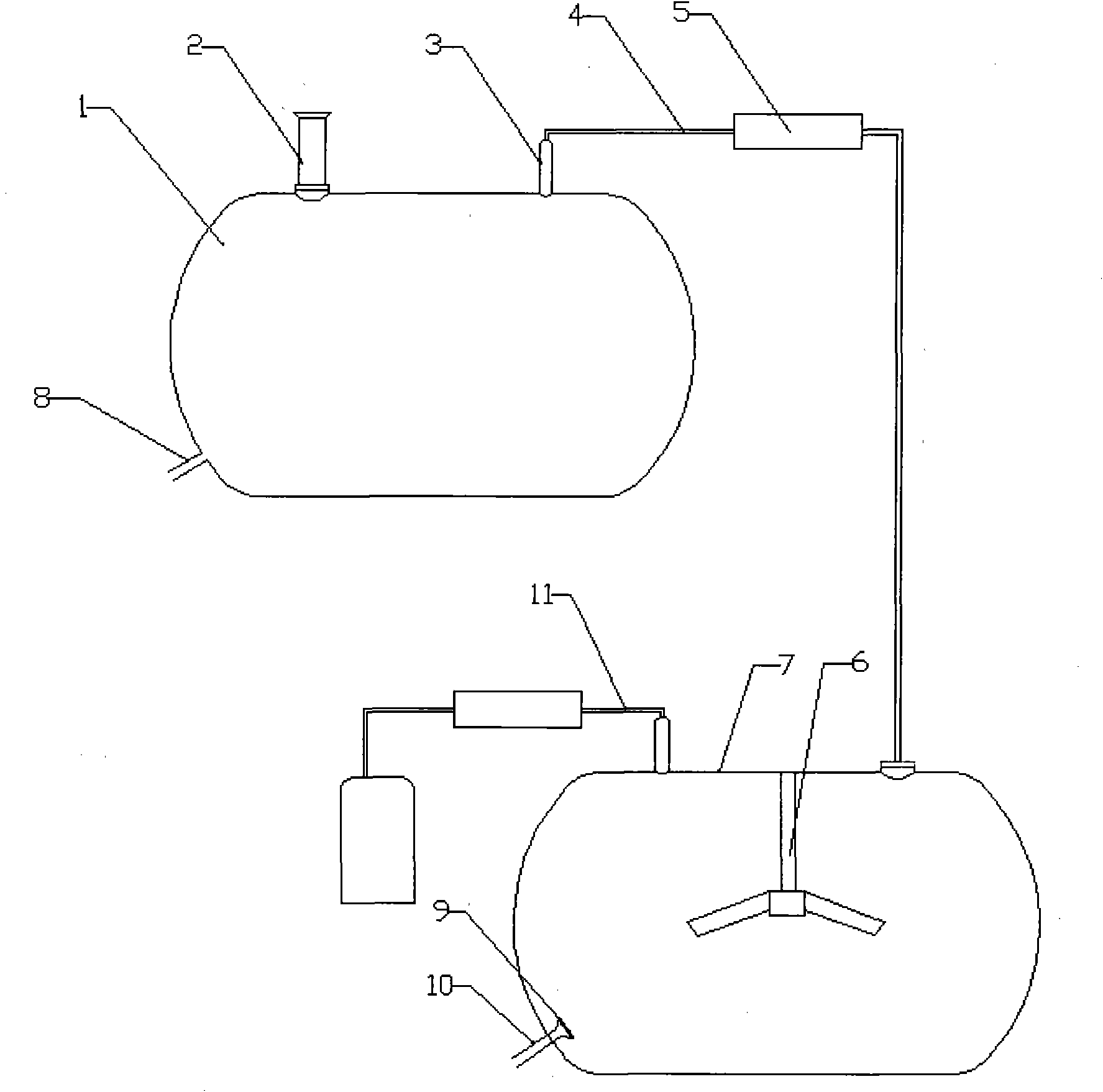

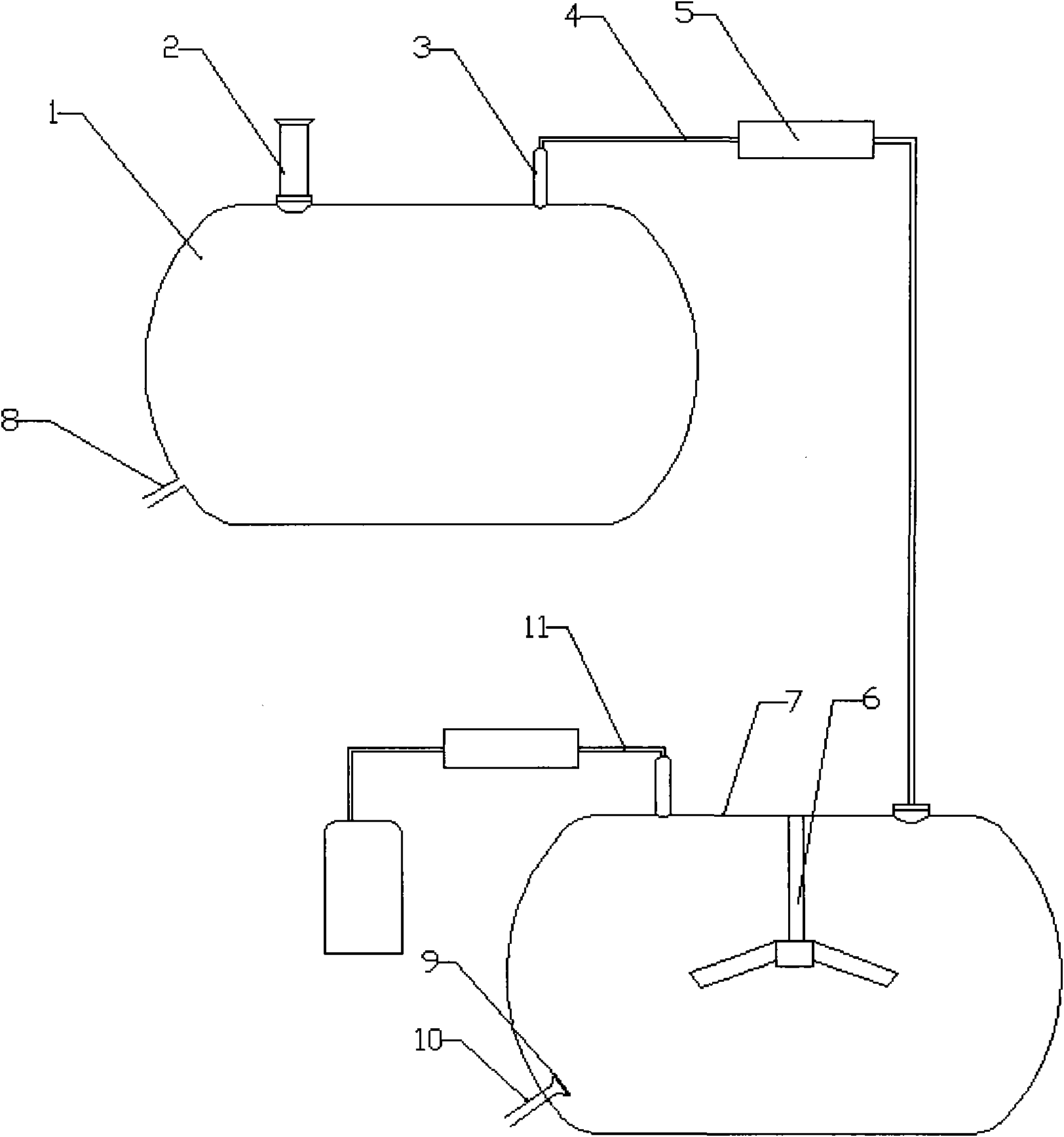

[0012] The invention is a device for producing diesel oil from coal tar, such as figure 1 As shown, it includes a separation reactor 1 with a feed inlet 2, a fractionation device 3 is provided at the top of the separation reactor 1, and a slagging outlet 8 is provided at the bottom, and the fractionation device 3 is connected with a belt outlet through a conduit 4. The synthetic reactor 7 of the oil port 10, and the agitator 6 is arranged in the synthetic reactor 7.

[0013] When producing diesel oil, the pretreated coal tar is sent into the separation reactor 1 through the feed port 2, and a liquid phase catalyst is added at the same time. The coal tar that enters the separation reactor 1 is gasified and separated. After gasification, the gas enters the fractionation devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com