Membrane for guiding regeneration of oral bone tissue and preparation method thereof

A technology for bone tissue regeneration and oral cavity, which is applied in tissue regeneration, non-woven fabrics, textiles and paper making, etc. It can solve the problems of induced inflammation, loss of magnesium and polymer scaffolds, and surrounding tissue irritation, so as to accelerate the speed of bone healing, Improves recovery rate and suppresses inflammatory response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

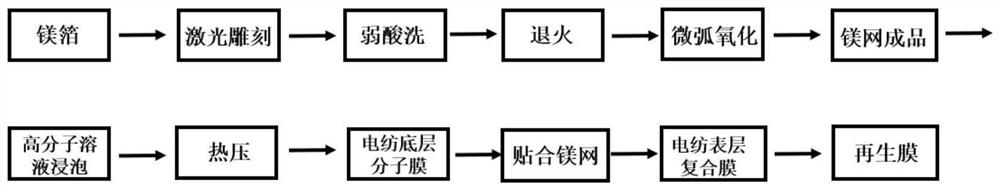

[0033] A method for preparing a film for guiding oral cavity bone tissue regeneration according to the present invention comprises the following steps:

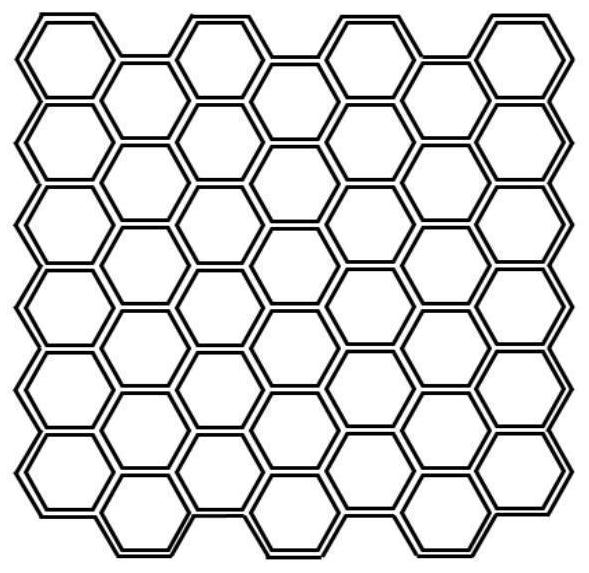

[0034] Step 1 Carve the pure magnesium or magnesium alloy foil into porous pure magnesium or magnesium alloy mesh 002, pretreat the porous pure magnesium or magnesium alloy mesh 002, then immerse in the degradable polymer solution, air-dry naturally and then hot press Processing, porous pure magnesium or magnesium alloy mesh can be made by a variety of different generalizations, for example: laser engraving technology can be used, the process parameters adopted for laser engraving are wavelength λ=1064nm, laser power P=20W, and the hole shape can be Regular hexagon, regular triangle, rhombus, square, circle and other geometric shapes, and the actual area of the porous pure magnesium or magnesium alloy mesh is 20-40% of the area of the pure magnesium or magnesium alloy foil, pure magnesium or magnesium alloy The thickness ...

Embodiment 1

[0043] (1) Using a magnesium plate with a purity of 99.9% as a material, it is hot-rolled to a thickness of 150 μm, and laser engraving technology is used to engrave regular hexagonal holes that account for 20% of the actual area and are evenly distributed on the foil.

[0044] (2) pickling with 5% glacial acetic acid for 30s, and annealing at 150°C for 20min after natural drying.

[0045] (3) Micro-arc oxidation treatment: at 12.5g / L Na 2 SiO 3 , 4.5g / L Na 3 PO 4 , in the electrode solution of 2.5g / L NaOH, the surface treatment was performed at a frequency of 450Hz and a current of 3.8A under direct current mode, the working voltage was increased to 260V, and the micro-arc oxidation treatment was performed for 15min; finally, the magnesium mesh was washed three times with deionized water and placed in Let dry naturally.

[0046] (4) Soak the magnesium mesh in a polycaprolactone (PCL) solution with a concentration of 0.1 g / mL and HFIP as a solvent for 60 min, take it out a...

Embodiment 2

[0051] (1) Using Mg-Zn alloy sheet with a magnesium content of more than 98% as raw material, it is hot-rolled at 200°C to a thickness of 200 μm, and laser engraving technology is used to engrave evenly distributed diamond-shaped holes on the foil that account for 30% of the actual area .

[0052] (2) pickling with 5% glacial acetic acid for 30s, and annealing at 180°C for 20min after natural drying.

[0053] (3) Micro-arc oxidation treatment: at 13.0g / L Na 2 SiO 3 , 5.0g / L Na 3 PO 4 , in the electrode solution of 2.5g / L NaOH, the surface treatment was performed at a frequency of 500Hz and a current of 3.8A under direct current mode, the working voltage was increased to 260V, and the micro-arc oxidation treatment was performed for 20min; finally, the magnesium mesh was washed three times with deionized water and placed in Let dry naturally.

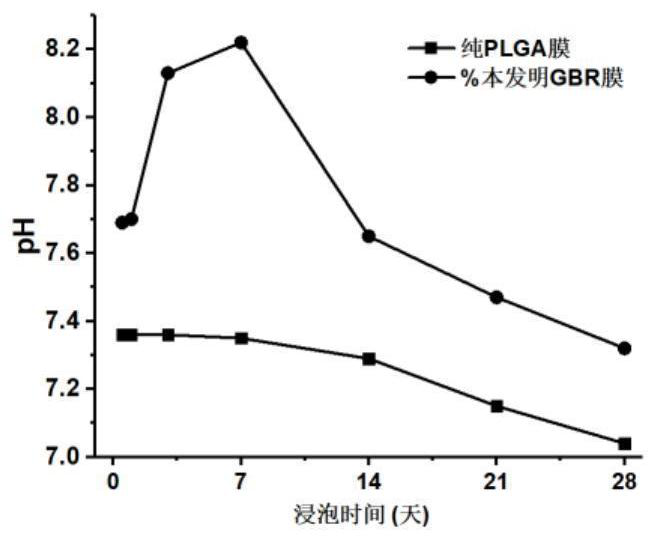

[0054] (4) Soak the magnesium mesh in a polylactic-co-glycolic acid (PLGA) solution with a concentration of 0.12 g / mL and a solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com