Continuous solid-state fermentation process and device for preparing fuel ethanol

A solid-state fermentation and fuel ethanol technology, applied in solid-phase fermentation bioreactors, fermentation, biofuels, etc., can solve the problems of high pretreatment cost of liquid fermentation raw materials, low production efficiency of solid-state fermentation, low ethanol yield, etc., to achieve The effect of saving manpower, saving time and manpower, improving product quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

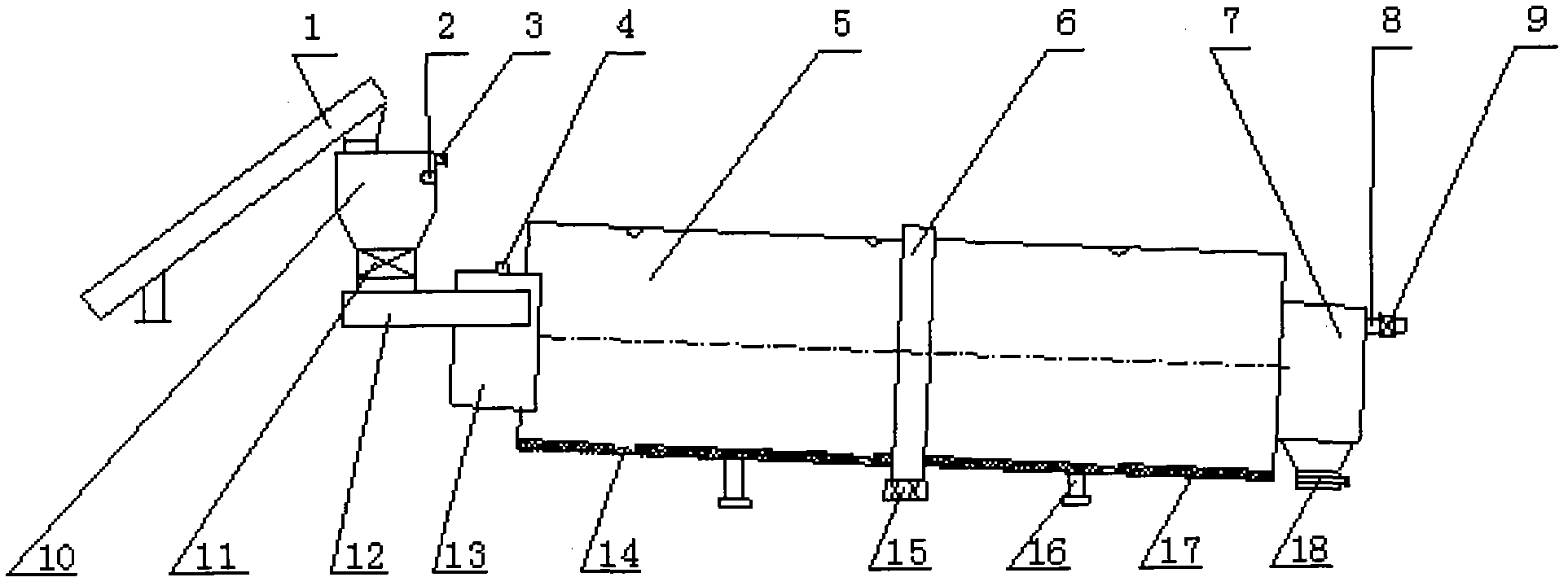

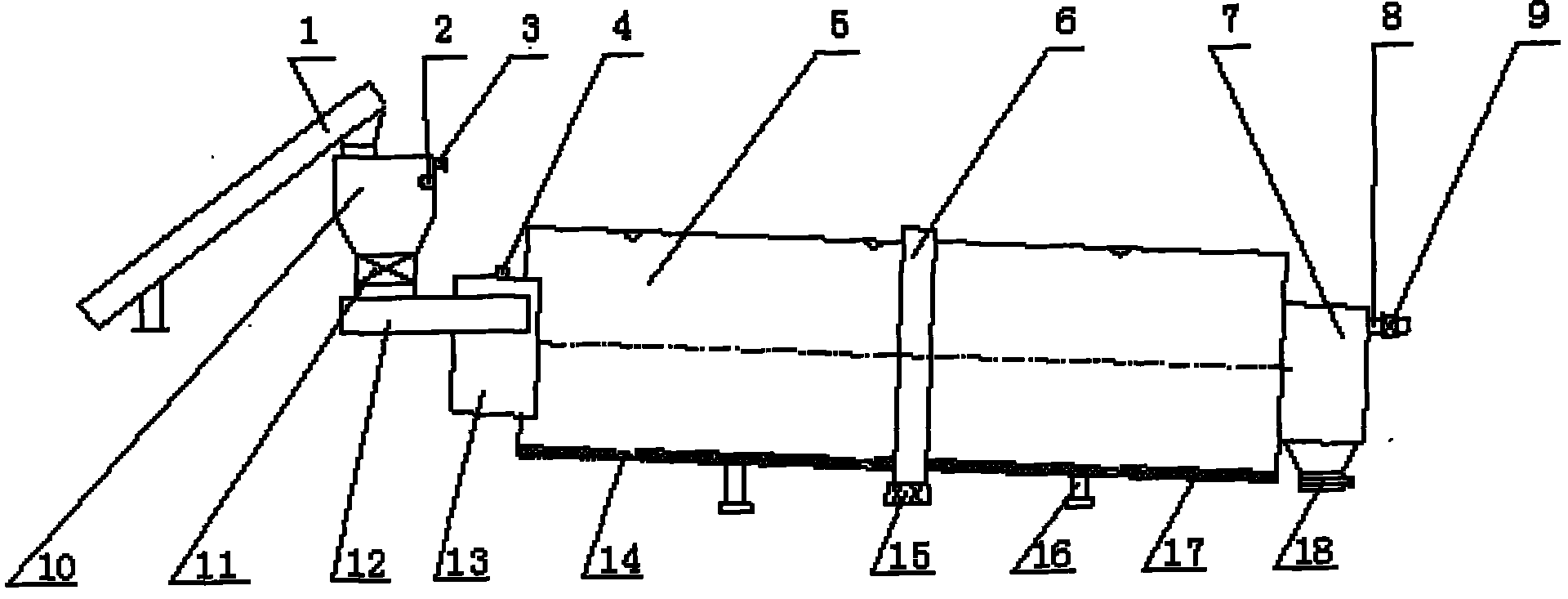

[0033] The mature sweet sorghum stalks are harvested, and sweet sorghum stalks with a water content of 70%, a total sugar content of 11%, and a reducing sugar content of 7% are used as raw materials, and they are crushed into filaments with a diameter of 1 to 2 mm and a length of less than 30 mm. At the same time, the TSH-Sc-001 strain is added to the closed silo, mixed with the crushed materials, and then continuously fermented in the continuous solid-state fermentation tank. The inoculation amount of the fermenting bacteria is 10% (V / W), the operating parameters are adjusted, the temperature in the tank is maintained at 30-36°C, the fermentation time is 30h, and the rotation speed of the fermentation tank is 0.25rpm. After fermentation, the ethanol yield was 92.2% and the total sugar conversion rate was 98.6%.

Embodiment 2

[0035] The mature sweet sorghum stalks are harvested, and the sweet sorghum stalks with a water content of 70%, a total sugar content of 12%, and a reducing sugar content of 8% are used as raw materials and crushed into filaments with a diameter of 1 to 2 mm and a length of less than 30 mm. At the same time, the TSH-Sc-001 strain is added to the closed silo, mixed with the crushed materials, and then continuously fermented in the continuous solid-state fermentation tank. The inoculation amount of the fermentation bacteria is 10% (V / W), and the operating parameters are adjusted to maintain the temperature in the tank at 30-36°C, the fermentation time is 36 hours, and the rotation speed of the fermentation tank is 0.1 rpm. After fermentation, the ethanol yield was 94.1%, and the total sugar conversion rate was 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com