Double-layer water-adsorption and moisture-transfer non-woven fabric and preparation method thereof

A non-woven, double-layer technology, applied in the field of non-woven fabrics and its preparation, can solve problems such as complex structure and processing technology, and achieve the effects of simple structure, broad market prospect and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

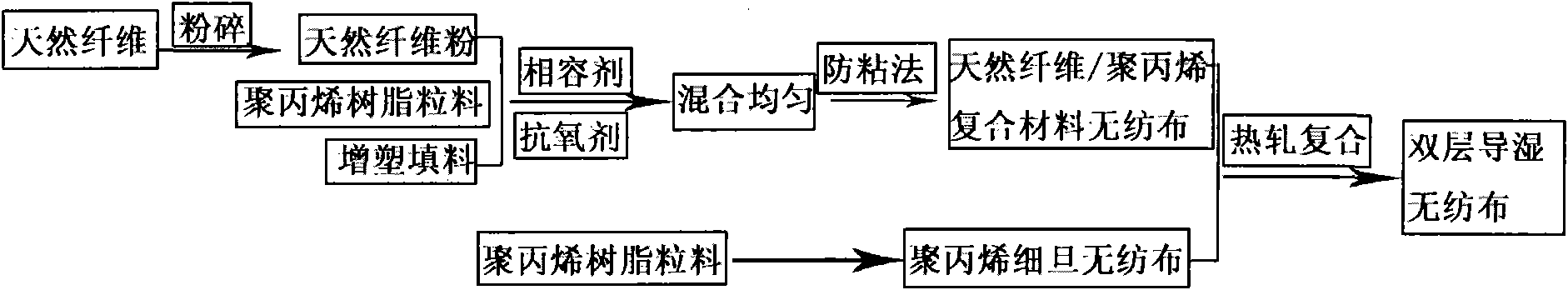

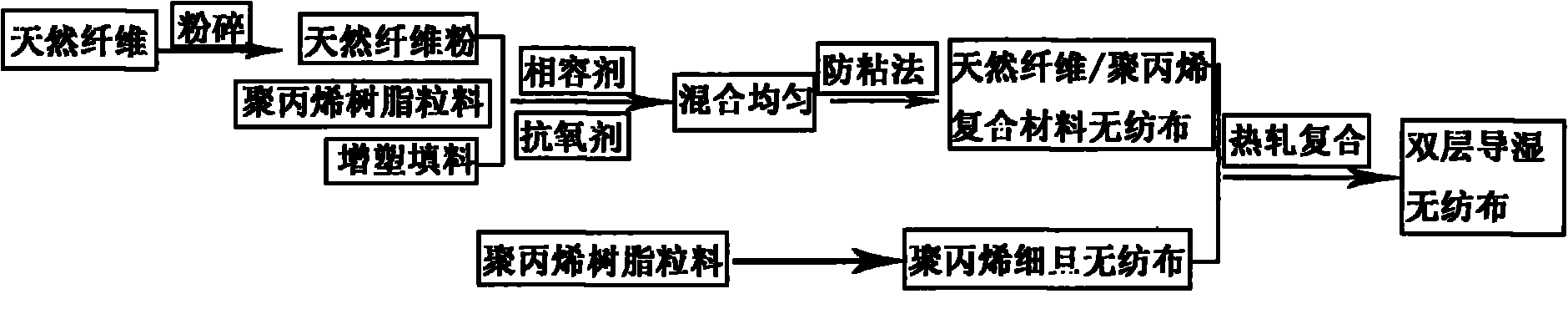

Method used

Image

Examples

Embodiment

[0029] Get dried polypropylene resin pellets, natural fibers, compatibilizers, antioxidants and toughening materials according to the components and weight ratios in Table 1.

[0030] Crush the kapok into a powder with a particle size of 50-220 mesh, dry it at 45°C, and then add polypropylene resin pellets, compatibilizers, antioxidants and toughening materials to it, mix evenly, and extrude, melt, Filtration and impurity removal, metering spinning, cooling and drawing, web-forming hot rolling and roll cold winding steps (wherein, the extrusion melting temperature is 150-230°C, the melt flow rate is 10-50g / 10min, and the draw ratio is 1.5-4 times, the winding speed is 20-250m / min), and the inner layer of the double-layer water-absorbing and moisture-conducting non-woven fabric is obtained.

[0031] Take another appropriate amount of polypropylene resin pellets, dry the polypropylene resin pellets at 70-90°C, extrude and melt, filter and remove impurities, meter spinning, cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com