Cation type chitosan bonded and modified capillary electrochromatography open tubular column and manufacturing method thereof

A technology of capillary electrochromatography and cationic chitosan, which is applied in the field of capillary electrochromatography, can solve problems such as poor stability, achieve the effects of avoiding adsorption, good reproducibility, and broad development and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: chemical bonding method prepares the open-tubular column modified by carboxymethyl chitosan

[0014] Pour the toluene solution of 30% γ-aminopropyltriethoxysilane into the activated capillary, seal both ends, heat in a gas chromatography furnace at 110°C for 24 hours, take it out and cool it to room temperature, rinse it with toluene and methanol respectively After 0.5 hours, blow dry with nitrogen. The silane-siliconized capillary column was washed with 10% glutaraldehyde (prepared in 50 mM phosphate buffer at pH 8.0) for 1 hour, and then washed with deionized water until neutral to complete the aldehyde group modification of the capillary. Continue to inject 0.2%-0.8% carboxymethyl chitosan solution into the aldehyde-modified capillary, seal both ends, bathe in 60°C water for 1 hour, and blow out the excess solution with nitrogen; finally use 10% glutaraldehyde (pH 8.0 50mM Phosphate buffer) was reacted at room temperature for 1 hour, washed with deioni...

Embodiment 2

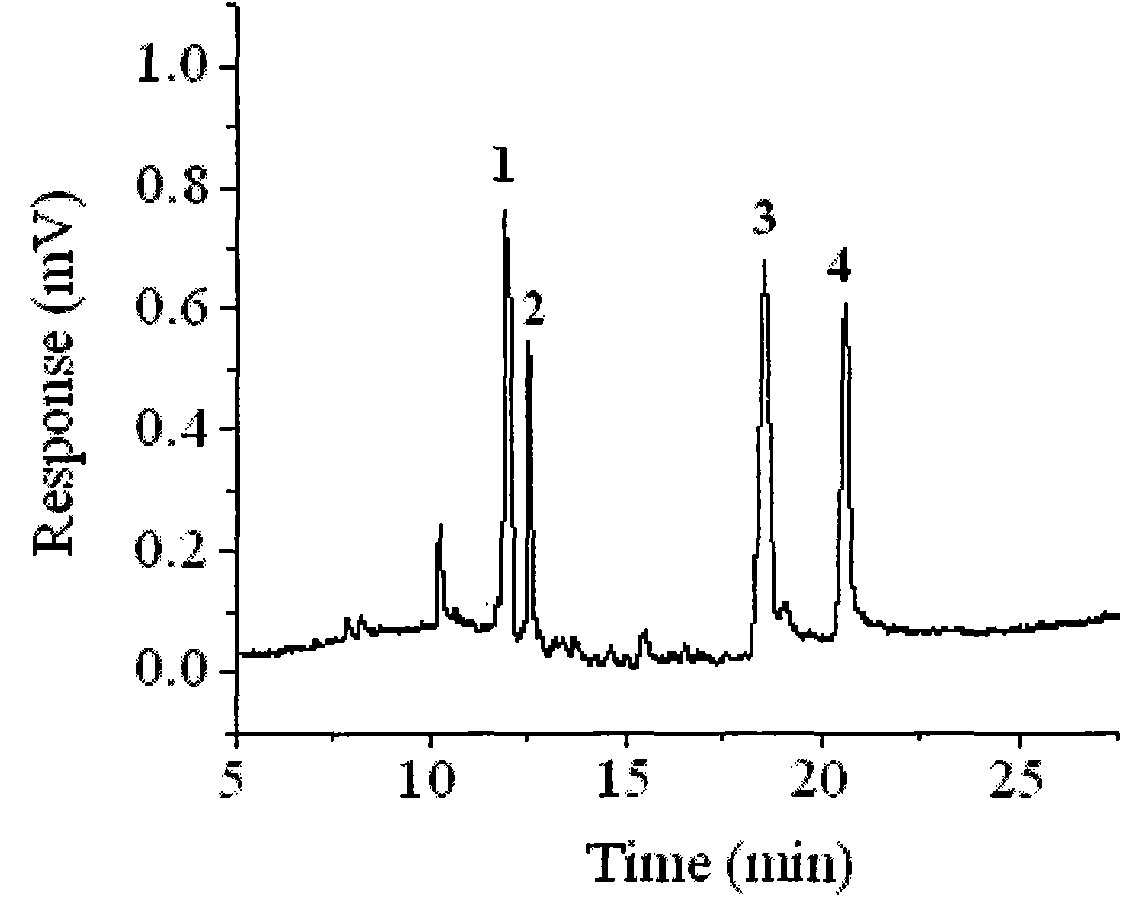

[0015] Example 2: Separation of basic proteins by carboxymethyl chitosan modified open-tubular column under anodic electroosmotic flow mode

[0016] Carboxymethyl chitosan was used to modify the open-tubular column (inner diameter 50mm, total length 60.0cm, effective length 40.0cm), with pH 3.020mM phosphate buffer as the mobile phase, separation voltage +15kV, under the CEC anode electroosmotic flow mode , the four basic proteins of trypsin, ribonuclease, cytochrome and lysozyme were separated by point chromatography-ultraviolet detection, and the proteins were completely separated under the above conditions, as shown in figure 2 As shown, the elution peaks are: 1. Trypsin, 2. Ribonuclease, 3. Cytochrome C, 4. Lysozyme, which reduces the tailing phenomenon caused by protein adsorption.

Embodiment 4

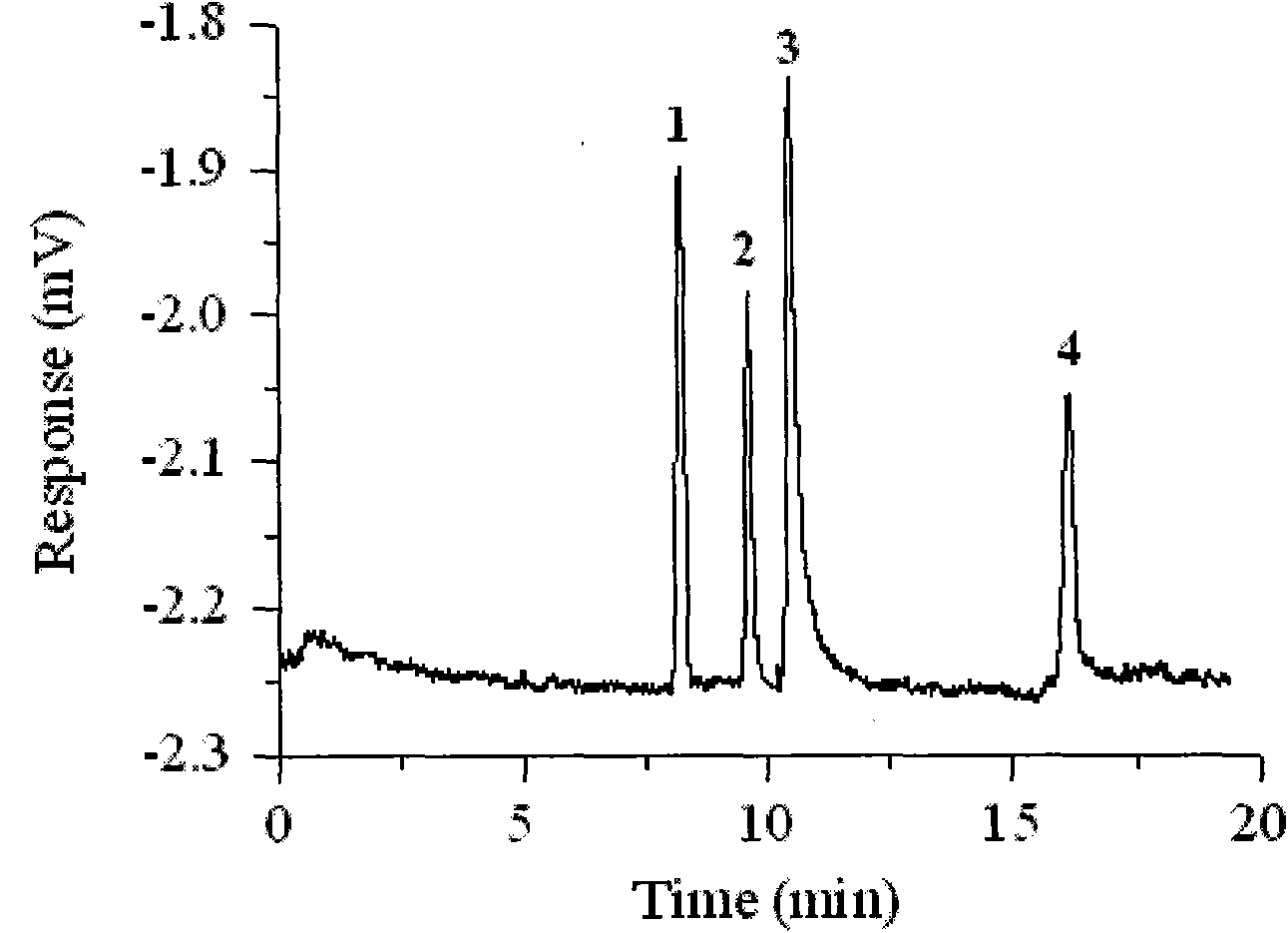

[0017] Example 4: Separation of alkaloids by carboxymethyl chitosan modified open-tubular column under cathodic electroosmotic flow mode

[0018] Carboxymethyl chitosan was used to modify the open-tubular column (inner diameter 50mm, total length 60.0cm, effective length 40.0cm), with pH 6.050mM phosphate buffer as the mobile phase, separation voltage +15kV, under the CEC cathodic electroosmotic flow mode , the four basic proteins of morphine, crowbarine, narcotin and papaverine were separated, as shown in Figure 3. The elution peaks are as follows: 1. Morphine, 2. Cybaine, 3. Nacodin, 4. Papaverine. Alkaloids were baseline separated under the above conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com