Method for preparing carbon nano tube electrode

A carbon nanotube and electrode technology, applied in the field of carbon nanotube electrode preparation, can solve the problems of limited removal ability of PPCPs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

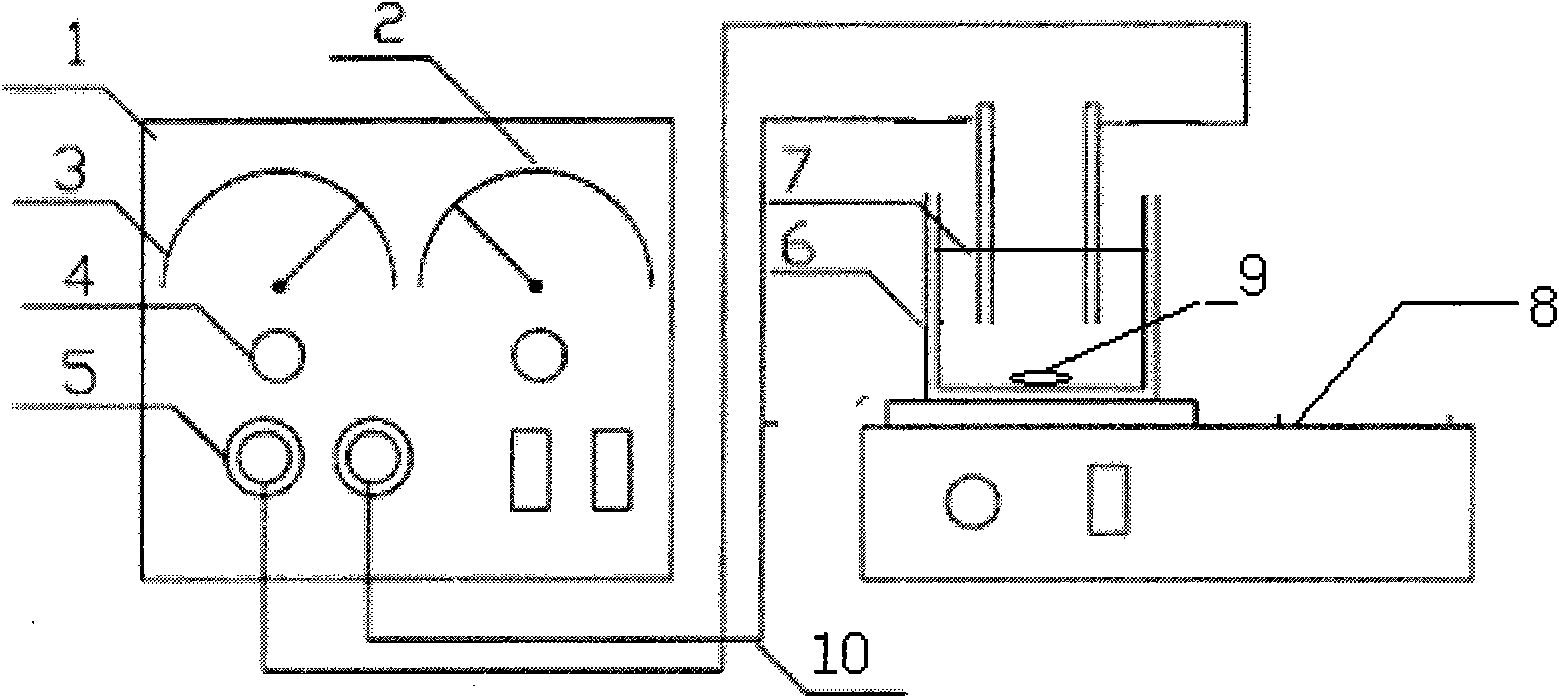

Image

Examples

Embodiment

[0026] Example: Electrolysis of triclosan with a palladium-coated carbon nanotube electrode.

[0027] First prepare a certain concentration of triclosan solution (in which the supporting electrolyte is sodium sulfate, the concentration is 1000mg / L), after adjusting the pH with NaOH and sulfuric acid, add it to the electrolytic cell, start the magnetic stirrer, set the electrolysis voltage to 30V, and Start the electrolysis at the next step, and after 10 hours of electrolysis, the removal rate of triclosan reaches more than 95%, and the dechlorination rate reaches 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com