High-temperature lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve problems affecting battery electrical performance and other issues, achieve high capacity retention rate and capacity recovery rate, and strong operability , the effect of no vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, when preparing the electrolyte: first in a glove box full of argon (H 2 O content6 ), uniformly mixed to be prepared as a mixed lithium salt solution with a concentration of 1mol / L. At the same time, in the mixed lithium salt solution, first add lithium bisoxalate borate LiBOB as a high-temperature film-forming additive and the mass percentage between the added lithium bisoxalate borate LiBOB and the mixed lithium salt solution is 1 %, in the actual preparation process, the mass percentage between lithium bisoxalate borate LiBOB and the mixed lithium salt solution can be adjusted accordingly in the range of 0.2% to 3% according to actual needs; then add ionic liquid EMI-TFSI as Inhibit high-temperature gas production additives, and the mass percentage between the added ionic liquid EMI-TFSI and the mixed lithium salt solution is 3%. In the actual preparation process, the high-temperature gas production inhibitors can be combined with the The mass pe...

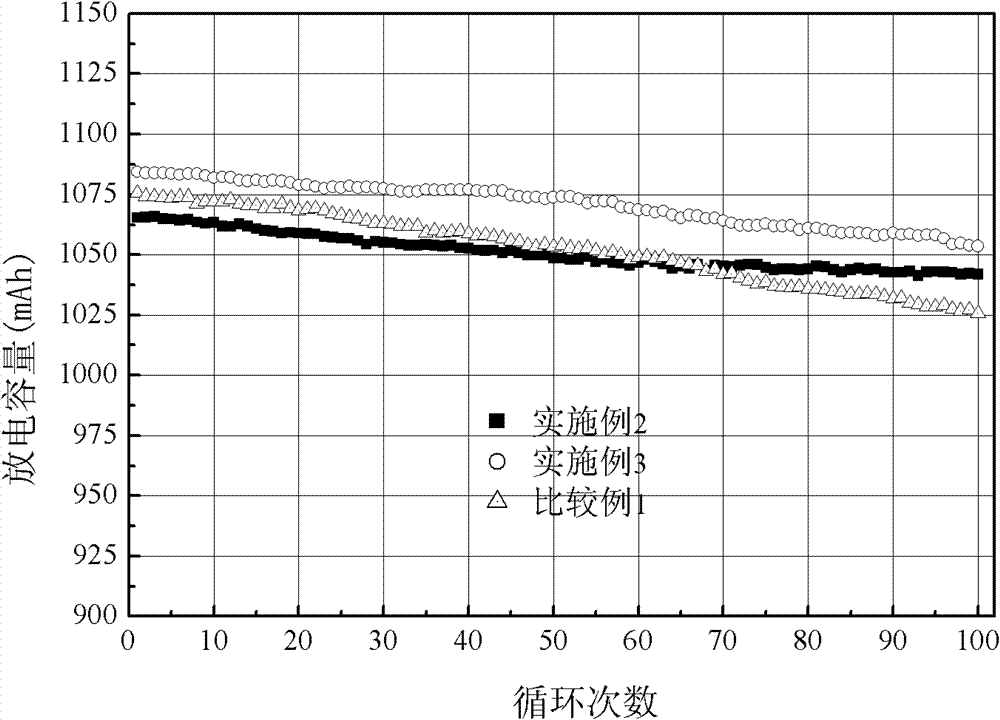

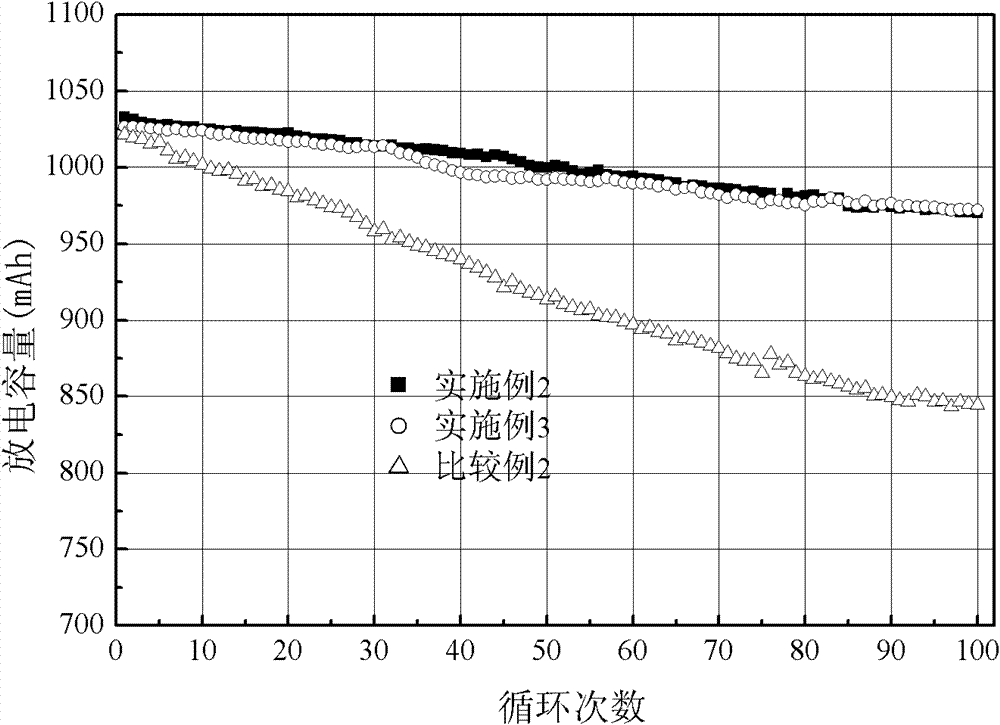

Embodiment 2

[0042] In the present embodiment, the difference from Example 1 is: when preparing the electrolyte: in a glove box full of argon (H 2 O content6 ), uniformly mixed and prepared into a mixed lithium salt solution with a concentration of 1.1 mol / L. At the same time, in the mixed lithium salt solution, first add lithium bisoxalate borate LiBOB as a high-temperature film-forming additive and the mass percentage between the added lithium bisoxalate borate LiBOB and the mixed lithium salt solution is 0.5 %; then add ionic liquid BMI-TFSI as an additive to suppress high-temperature gas production, and the mass percentage between the added ionic liquid BMI-TFSI and the mixed lithium salt solution is 5%. To be electrolyte salt (ie lithium hexafluorophosphate LiPF 6 ) after fully dissolving, let it stand for 24 hours to obtain high-temperature lithium-ion battery electrolyte.

[0043] In this embodiment, the manufacturing method steps and required materials for manufacturing a lithium...

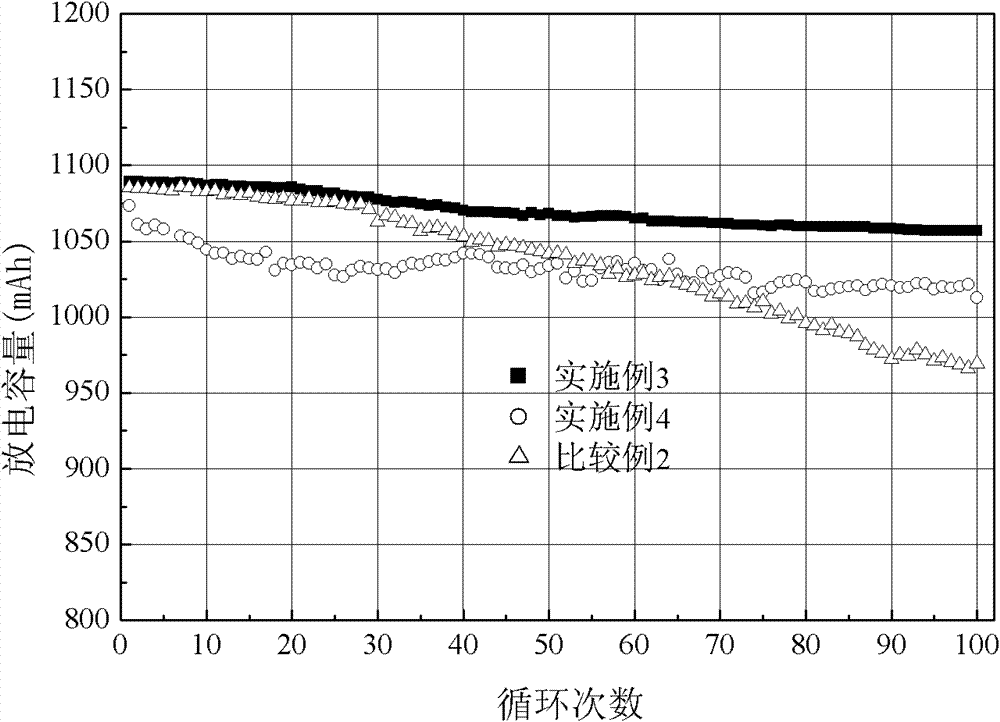

Embodiment 3

[0045] In this embodiment, the difference from Example 1 is: when preparing the electrolyte: first in a glove box full of argon (H 2 O content6 ), uniformly mixed and prepared into a mixed lithium salt solution with a concentration of 0.8mol / L. At the same time, in the mixed lithium salt solution, first add lithium bisoxalate borate LiBOB as a high-temperature film-forming additive and the mass percentage between the added lithium bisoxalate borate LiBOB and the mixed lithium salt solution is 2 %; Add the mixed additive mixed with ionic liquid PMI-TFSI and phthalic anhydride as the high-temperature gas production additive, and the mass percentage between the added ionic liquid PMI-TFSI and the mixed lithium salt solution is 5%, the mass percentage between the added phthalic anhydride and the mixed lithium salt solution is 4%. To be electrolyte salt (ie lithium hexafluorophosphate LiPF 6 ) after fully dissolving, let it stand for 24 hours to obtain high-temperature lithium-io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com