Acrylic polyurethane modified tung oil-imide addition product and preparation method thereof

A technology of acrylic polyurethane and tung oil imide, applied in polyester coatings, coatings, etc., can solve the problems of fast curing speed and slow curing epoxy speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

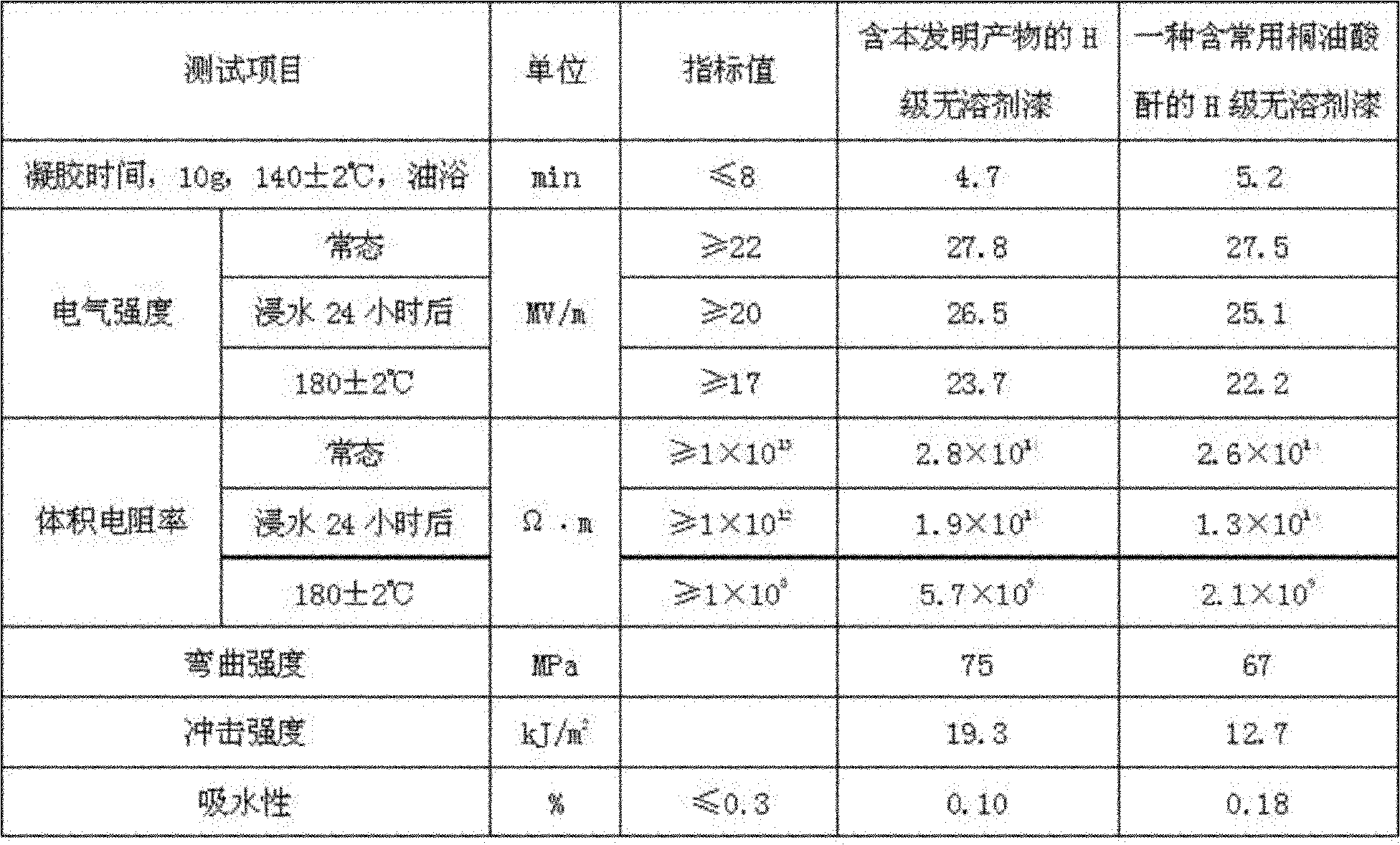

Image

Examples

Embodiment 1

[0020] Take 1,000 grams of refined dehydrated tung oil and add it to the reactor, start stirring, heat to 90°C, gradually add 270 grams of maleic anhydride, raise the reaction temperature and control it at about 150°C, react for 40 minutes, and cool down to below 120°C. Gradually add 168 grams of ethanolamine, keep it below 140°C for 0.5 hours, fully form amic acid, then raise the temperature to 180°C, and carry out imide cyclization reaction. During the reaction, water will evaporate, keep at 180°C for 1 hour and then vacuumize and dehydrate . Cool down to below 100°C, add an appropriate amount of polymerization inhibitor MEHQ (p-methoxyphenol), add 600-800 grams of styrene to dilute, and cool down for later use, which is component one.

[0021] Add 479 grams of TDI to another reactor, and gradually drop 358 grams of hydroxypropyl acrylate to react with it. The process needs to be cooled and the reaction temperature should not be higher than 60 ° C. After the reaction is comp...

Embodiment 2

[0024] Take 1000 grams of refined dehydrated tung oil into the reactor, start stirring, heat to 90°C, gradually add 275 grams of maleic anhydride, raise the reaction temperature and control it at about 150°C, react for 40 minutes, and cool down to below 120°C. Gradually add 171 grams of ethanolamine, keep it below 140°C for 0.5 hours, fully form amic acid, then raise the temperature to 180°C, and carry out imide cyclization reaction. During the reaction, water will evaporate, keep at 180°C for 1 hour and then vacuumize and dehydrate . Cool down to below 100°C, add an appropriate amount of polymerization inhibitor MEHQ (p-methoxyphenol), add 600-800 grams of styrene to dilute, and cool down for later use, which is component one.

[0025] Add 489 grams of TDI to another reactor, and gradually add 365 grams of hydroxyethyl methacrylate to react with it. The process needs to be cooled and the reaction temperature should not be higher than 60 ° C. After the reaction is completed, i...

Embodiment 3

[0028] Take 1000 grams of refined dehydrated tung oil into the reactor, start stirring, heat to 90°C, gradually add 250 grams of maleic anhydride, raise the reaction temperature and control it at about 150°C, react for 40 minutes, and cool down to below 120°C. Gradually add 156 grams of ethanolamine, keep it below 140°C for 0.5 hours, fully form amic acid, then raise the temperature to 180°C, and carry out imide cyclization reaction. During the reaction, water will evaporate, keep at 180°C for 1 hour, then vacuumize and dehydrate . Cool down to below 100°C, add an appropriate amount of polymerization inhibitor MEHQ (p-methoxyphenol), add 600-800 grams of styrene to dilute, and cool down for later use, which is component one.

[0029] Add 445 grams of TDI to another reactor, and gradually add 368 grams of hydroxypropyl methacrylate to react with it. The process needs to be cooled and the reaction temperature should not be higher than 60 ° C. After the reaction is completed, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com