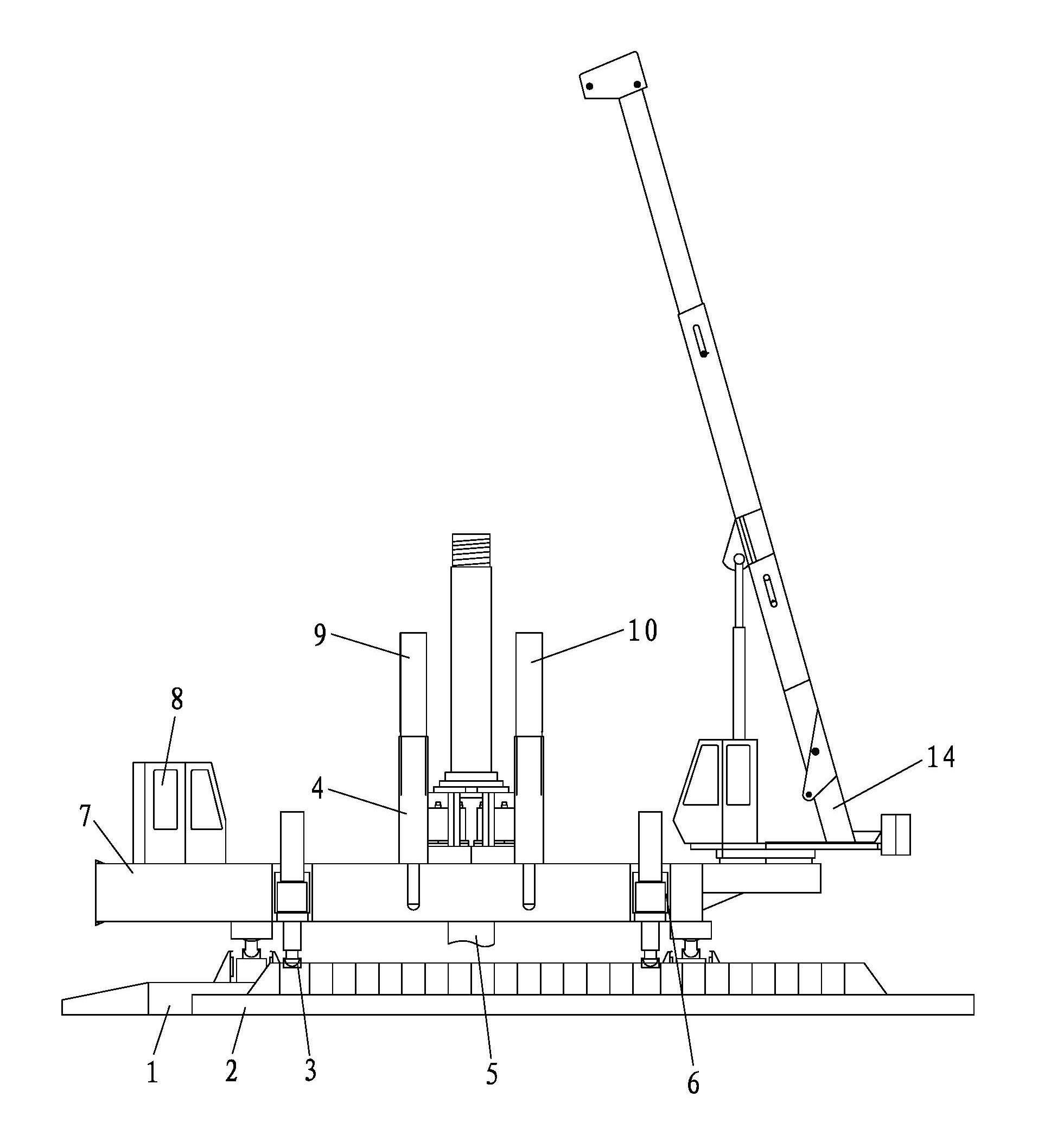

Rammed pedestal pile back pressure device of immersed tube filling pile machine

A technology of sinking pipe grouting piles and bottom-expanding piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve problems such as difficult pile top elevation, inability to construct rammed and expanded bottom piles, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

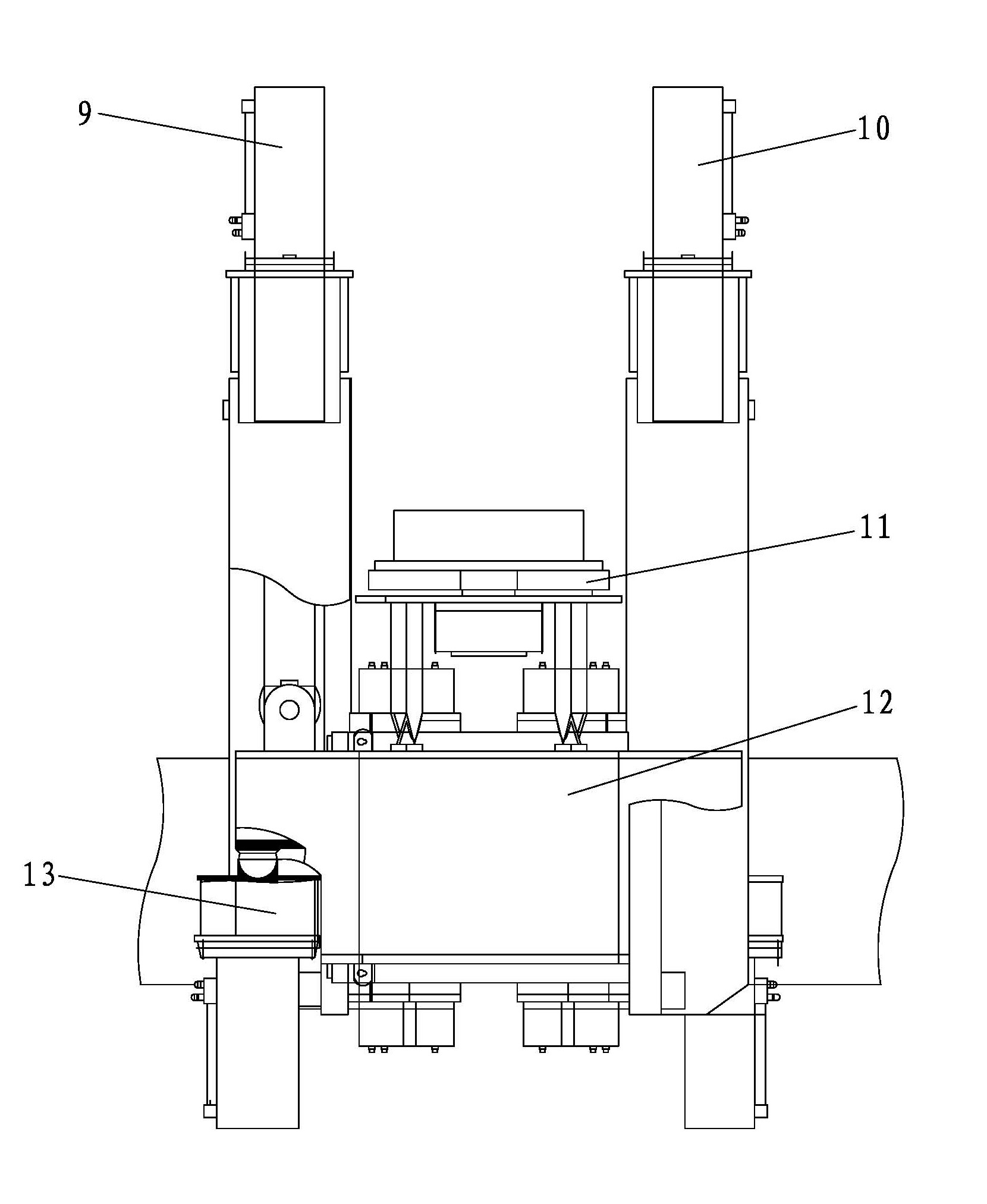

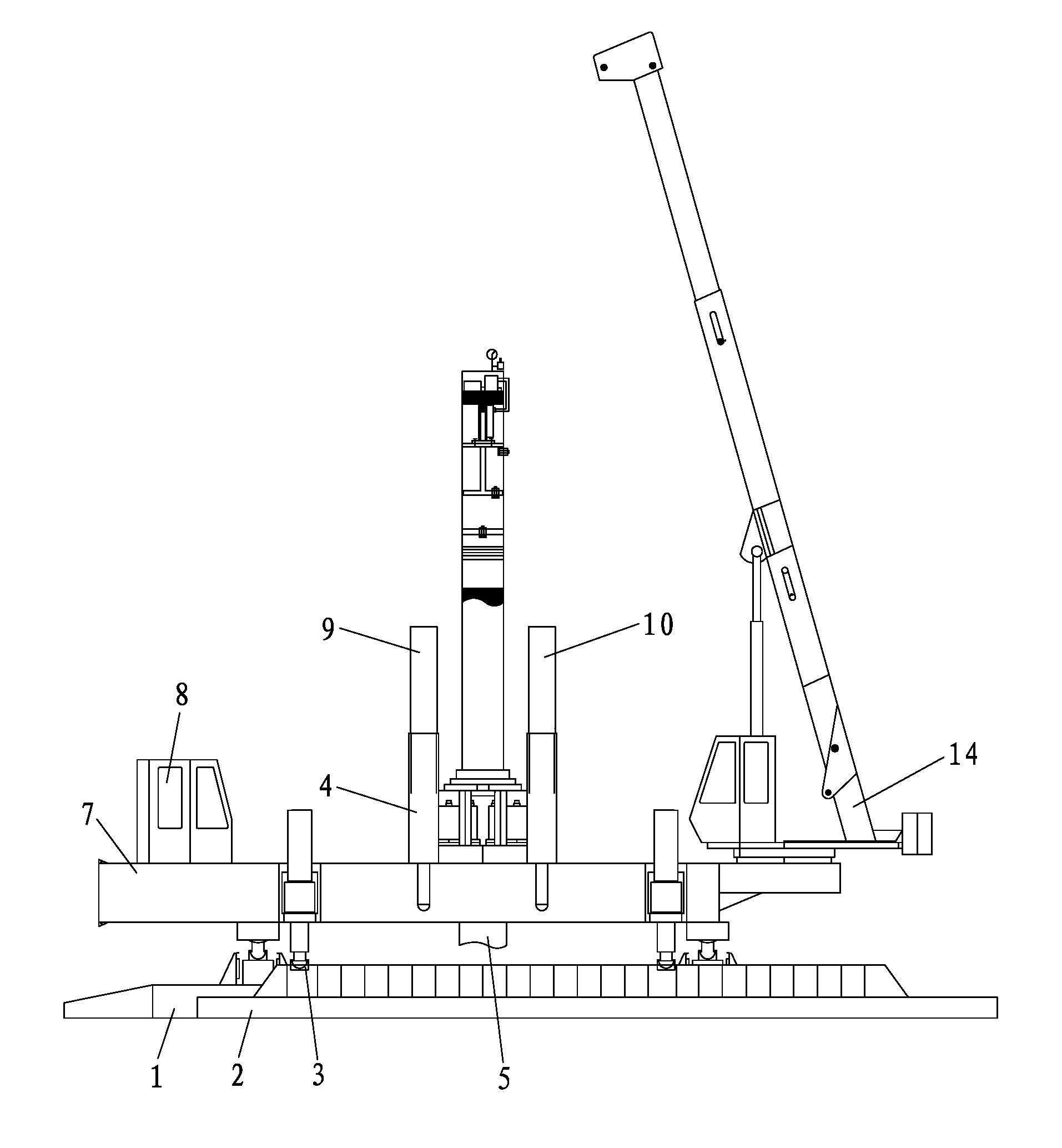

[0036] see picture image 3 and Figure 4 , The construction ramming and expansion bottom pile back pressure device of the sinking tube grouting pile machine disclosed by the present invention includes a main body 15, a power unit 16, a back pressure cylinder 17, a piston body 18, and one-way valves 19, 20 and 21. The structure and background of the immersed tube grouting pile driver are the same, so they will not be described in detail.

[0037] The main body 15 is airtightly hinged on the upper end of the last construction steel pipe 5, so that the entire back pressure device is installed on the last construction steel pipe 5.

[0038] The power unit 16 , the back pressure cylinder 17 and the piston body 18 are installed in the main body 15 . The power unit 16 is made up of a motor 161 , an oil tank 162 , an oil pump 163 and an oil pipe 164 . The piston body 18 lower cavity and the construction steel pipe 5 and the reinforced concrete 23 in the construction steel pipe 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com