Method for preparing zinc phosphate and hydrate thereof with sodium hydrosulfite filter residues

A technology of zinc phosphate and sodium hydrosulfite, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of single use, inability to consume zinc powder waste residue, etc., achieving simple operation, less by-products, and low equipment investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

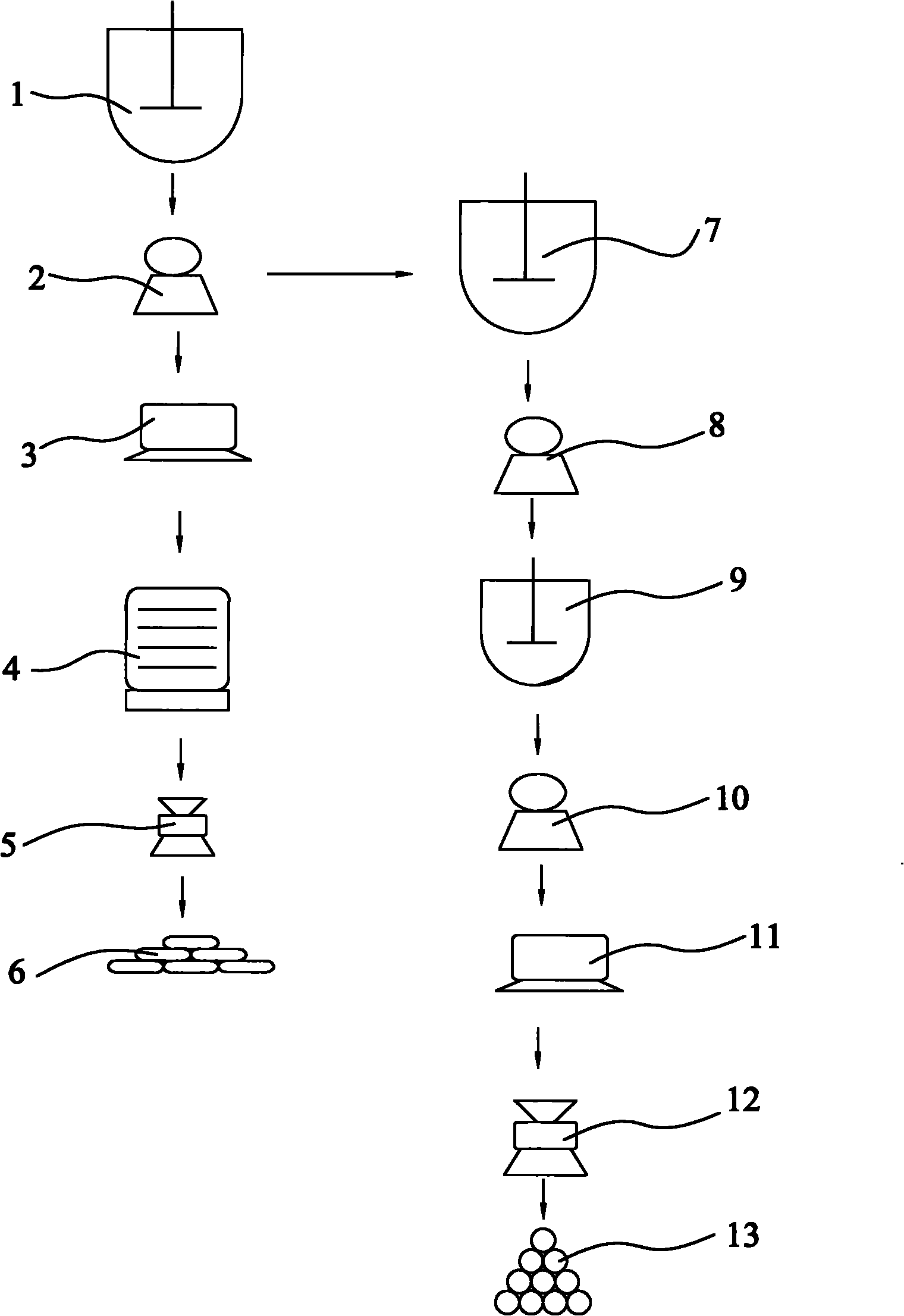

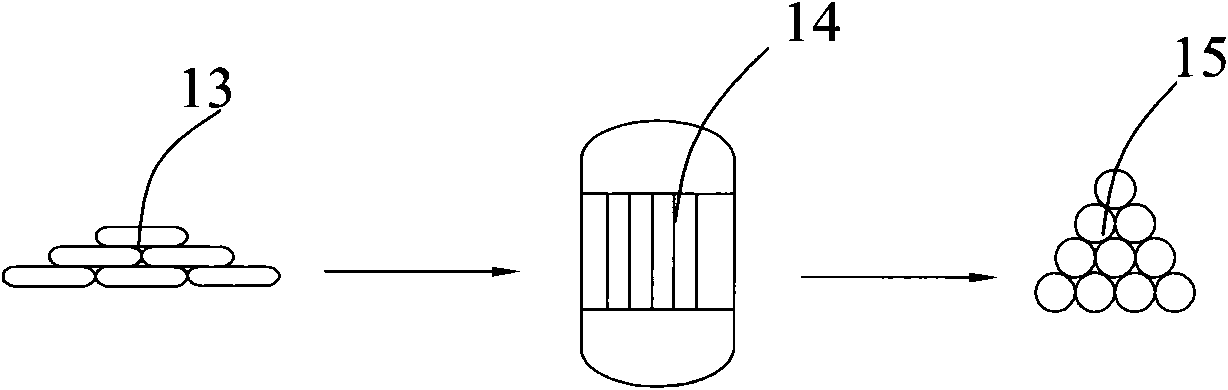

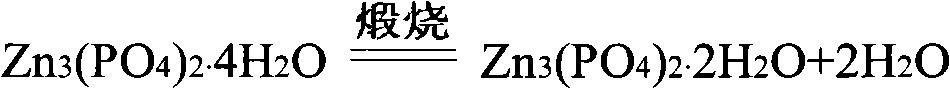

[0034] refer to figure 1 , a method for producing zinc phosphate and hydrate thereof with sodium hydrosulfite filter residue, get 495kg of sodium hydrosulfate filter residue, convert the content of zinc hydroxide in the filter residue of sodium hydrosulfite to be 297kg, and pulverize the sodium hydrosulfate filter residue, configure it into a suspension, Calcium chloride solution is configured simultaneously; the suspension and calcium chloride solution are dropped into the first corrosion-resistant reactor (1) successively by the pure substance mass ratio of zinc hydroxide and calcium chloride in a ratio of 1: 1.12, and carried out under stirring. chemical reaction to obtain a mixture containing zinc chloride and calcium hydroxide; the mixture containing zinc chloride and calcium hydroxide is filtered through the first filter (2) to obtain a clarified filtrate containing zinc chloride and calcium hydroxide white filter cake; the white filter cake containing calcium hydroxide ...

Embodiment 2

[0036] refer to figure 1, a method for producing zinc phosphate and hydrate thereof with sodium hydrosulfite filter residue, weighing 495kg of sodium hydrosulfite residue, converting the content of zinc hydroxide in the sodium hydrosulfite waste residue to 297kg, pulverizing the sodium hydrosulfite filter residue, and configuring it into a suspension, and simultaneously configuring Calcium chloride solution; put the suspension and calcium chloride solution into the first corrosion-resistant reactor (1) in turn according to the pure substance mass ratio of zinc hydroxide and calcium chloride of 1:0.92, and carry out the chemical reaction under stirring , to obtain a mixture containing zinc chloride and calcium hydroxide; the mixture containing zinc chloride and calcium hydroxide is filtered through the first filter (2), to obtain a clear filtrate containing zinc chloride and a white liquid containing calcium hydroxide Filter cake: the white filter cake containing calcium hydrox...

Embodiment 3

[0039] refer to figure 1 , a method for producing zinc phosphate and hydrate thereof with sodium hydrosulfite filter residue, weighing 495kg of sodium hydrosulfite residue, converting the content of zinc hydroxide in the sodium hydrosulfite waste residue to be 297kg, pulverizing the sodium hydrosulfite filter residue, and configuring it into a suspension, and simultaneously using Ammonia alkali waste liquid containing calcium chloride is prepared with calcium chloride solution; the suspension and calcium chloride solution are sequentially put into the first corrosion-resistant reactor according to the pure substance mass ratio of zinc hydroxide and calcium chloride at 1:1.32 In (1), chemical reaction is carried out under stirring to obtain a mixture containing zinc chloride and calcium hydroxide; the mixture containing zinc chloride and calcium hydroxide is filtered through the first filter (2) to obtain clarified chloride containing The filtrate of zinc and the white filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com