High temperature resistant broadband wave-transparent ceramic matrix composite and preparation method thereof

A composite material and ceramic-based technology, which is applied in the field of ceramic-based composite materials and its preparation, can solve the problems of unsatisfactory broadband transmission characteristics, large dielectric constant, and high cost, and achieve excellent ablation resistance and cracking temperature Low, the effect of reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

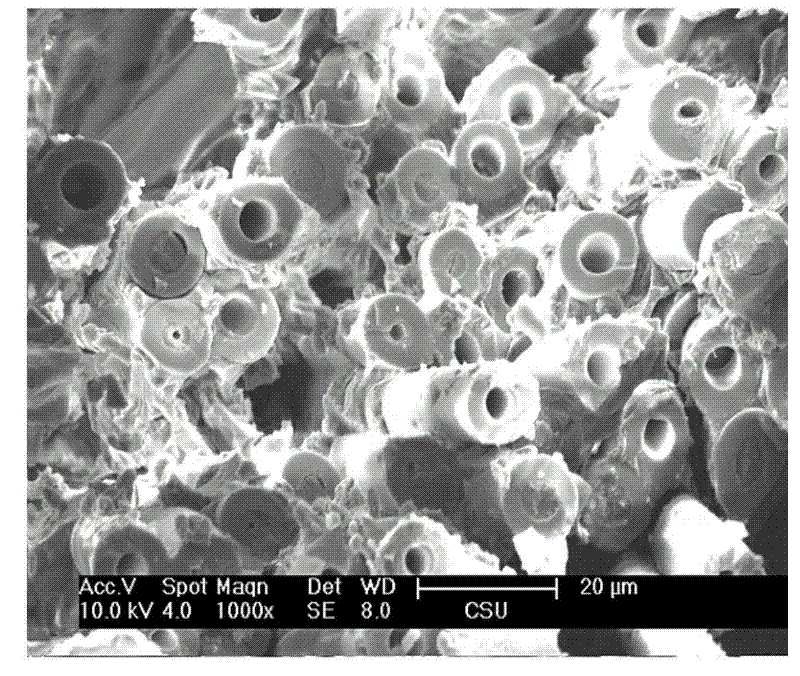

[0030] The reinforcing phase of the wave-transparent ceramic matrix composite material in this embodiment is hollow quartz fiber, and the matrix is carbon-free boron nitride (BN). The apparent volume fraction of the hollow quartz fiber is about 40%, and the actual fiber volume fraction is About 32% (because the quartz fiber has a hollow core), the volume fraction of the boron nitride is about 40%; the rest is pores.

[0031] preparation:

[0032] (1) Preparation of hollow quartz fiber preform

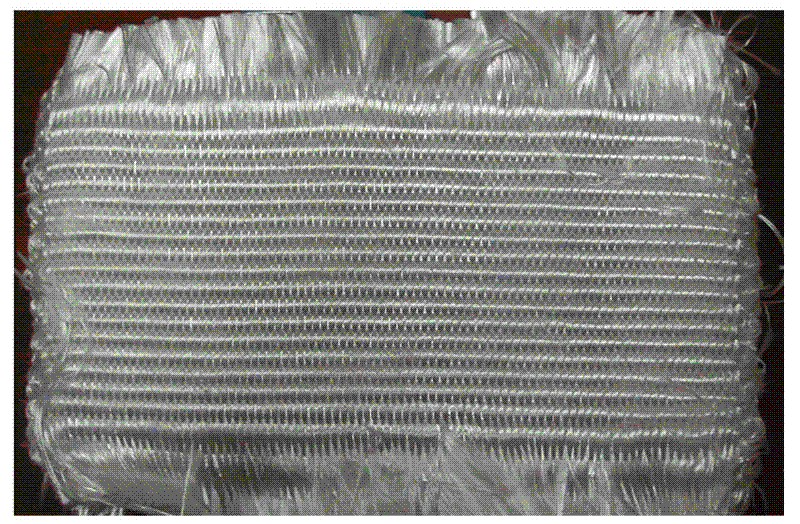

[0033] The high-purity hollow silica fiber (SiO in the fiber 2 content greater than 99.9wt%) woven into flat-shaped prefabricated parts, weaving method: 2.5-dimensional structure, fiber apparent volume fraction is about 40%, considering the hollowness of the fiber, the actual fiber volume fraction is about 32%; yarn specification 300tex, the linear densities of warp and weft are 10 threads / cm and 5 threads / cm respectively;

[0034] (2) Pretreatment of hollow quartz fiber preforms ...

Embodiment 2

[0040] The actual volume fraction of the hollow core quartz fiber of the wave-transparent ceramic matrix composite material in this embodiment is about 24% (because the quartz fiber has a hollow core), and the volume fraction of the matrix boron nitride is about 42%; the remainder is pores.

[0041] preparation:

[0042] (1) High-purity hollow silica fiber (SiO 2 Content greater than 99.9%) prepared into felt prefabricated flat panels (such as Figure 5 shown), the fiber apparent volume fraction is about 30%, and the actual fiber volume fraction is about 24%;

[0043] (2) Place the hollow quartz fiber preform obtained in step (1) in an impregnation tank, add acetone to immerse the fiber preform, close the impregnation tank, then place the impregnation tank in an oil bath, heat to 60°C and cook 5 hours; then it is cooled to room temperature and the acetone is taken out, then heated and vacuum-dried the fiber preform; so repeated 4 times until the acetone discharged after clea...

Embodiment 3

[0048] In this embodiment, the actual volume fraction of the hollow core quartz fiber of the wave-transparent ceramic matrix composite material is about 32% (because the quartz fiber has a hollow core), and the volume fraction of the matrix boron nitride is about 42%; the remainder is pores.

[0049] preparation:

[0050] (1) Same as the embodiment step (1)

[0051] (2) Place the hollow quartz fiber preform obtained in step (1) in an impregnation tank, add acetone to immerse the fiber preform, close the impregnation tank, then place the impregnation tank in an oil bath, heat to 60°C and cook 4 hours; then it was cooled to room temperature and the acetone was taken out, then heated and vacuum-dried the fiber preform; so repeated 4 times until the acetone discharged after cleaning was no longer turbid;

[0052] (3) After drying the pretreated fiber preform, put it into the impregnation tank, vacuumize the impregnation tank and inhale the carbon-free BN ceramic precursor until i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com