Method for preparing nano crystal cellulose by dissociating ZnCl2

A technology of nano-crystal and cellulose, which is applied in the field of preparation of nano-crystal cellulose, which can solve the problems of difficult control of cellulose degradation, generation of a large amount of acid waste liquid, and large corrosion of equipment, so as to achieve good mechanical strength and low corrosion of equipment , the effect of little degradation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

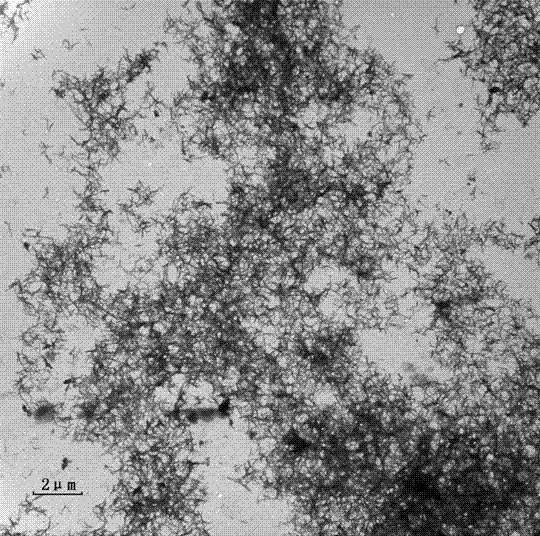

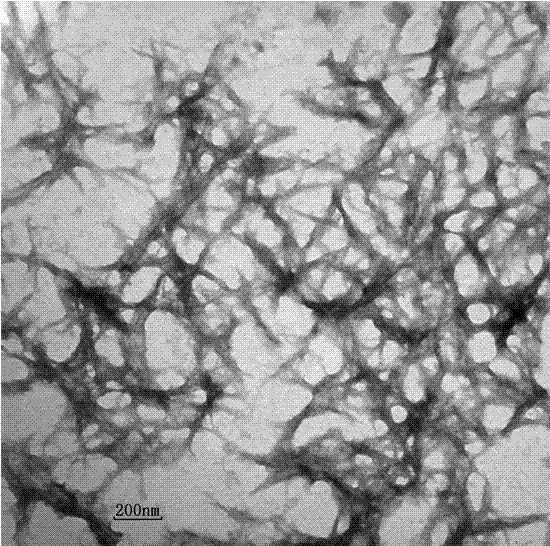

[0027] Take by weighing 3g microcrystalline cellulose, add to 30g mass fraction 65%ZnCl 2 In the solvent, 80 ° C oil bath for 1 hour, and at the same time high-speed dispersion homogeneous, the homogeneous speed is 12000 rpm, to obtain transparent cellulose / ZnCl 2 solution. Add 90ml of 0.5% hydrochloric acid to the cellulose / ZnCl 2 In the solution, the cellulose is precipitated, centrifuged and separated, and the upper layer of ZnCl is removed. 2 , acid solution, remove the cellulose jelly in the lower layer and perform centrifugation and elution with water for 5 times, remove the dissociated cellulose jelly in the crystallization area of the lower layer and ultrasonicate at 50°C (ultrasonic frequency is 40KHz) for 2 hours, that is Nanocrystalline cellulose is obtained. It can be seen from the observation of the transmission electron microscope that the nanocrystalline microelements prepared by this method have a network structure, with a diameter of about 20-30nm and a...

Embodiment 2

[0029] Weigh 1g chemical pulp, add to 30g mass fraction 65%ZnCl 2 In the solvent, 80 ° C oil bath for 3 hours, at the same time, high-speed dispersion and homogeneity, the homogenization speed is 12000 rpm, to obtain transparent cellulose / ZnCl 2 solution. Add 105ml of 0.5% hydrochloric acid to the cellulose / ZnCl 2 In the solution, the cellulose is precipitated, centrifuged and separated, and the upper layer of ZnCl is removed. 2 , acid solution, remove the cellulose jelly in the lower layer and perform 8 times of centrifugation and elution with water, remove the dissociated cellulose in the crystallization area of the lower layer and ultrasonicate at 80°C (ultrasonic frequency is 60KHz) for 4 hours to obtain nanocrystals cellulose.

Embodiment 3

[0031] Weigh 1g absorbent cotton, add to 30g mass fraction 65%ZnCl 2 In the solvent, 100 ° C oil bath for 4 hours, at the same time, high-speed dispersion and homogeneity, the homogenization speed is 8000 rpm, to obtain transparent cellulose / ZnCl 2 solution. Add 105ml of 0.5% hydrochloric acid to the cellulose / ZnCl 2 In the solution, the cellulose is precipitated, centrifuged and separated, and the upper layer of ZnCl is removed. 2 , acid solution, remove the lower layer of cellulose jelly, and then centrifuge and elute with water for 6 times, remove the dissociated cellulose in the crystallization area of the lower layer and ultrasonicate at 80°C (ultrasonic frequency is 60KHz) for 4 hours to obtain nanocrystals cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com