Carbon black color master batch for polyethylene pipes and preparation method thereof

A technology of carbon black masterbatch and polyethylene, which is applied in the field of carbon black masterbatch for PE100 pipes and its preparation, can solve the problems of undeveloped carbon black masterbatch for PE100 pipes, and achieve good anti-ultraviolet aging, high performance and mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In a second aspect of the present invention, a method for preparing carbon black masterbatch for polyethylene pipes is provided, the method comprising:

[0058] The carbon black of 35-100 weight part is mixed with the butylbenzene pyridine copolymer of 1.75-20 weight part;

[0059] Add 100 parts by weight of ultra-high molecular weight polyethylene with a molecular weight of 1.50-4 million (preferably about 2.5 million) and an antioxidant of 0-10 parts by weight into the mixture, mix uniformly and then discharge to obtain the polyethylene pipe. Carbon black masterbatch.

[0060] Preferably, 35-100 parts by weight of the carbon black and 1.75-20 parts by weight of the butylfenene copolymer are mixed in an internal mixer.

[0061] Preferably, the butylfenazole copolymer is prepared by emulsion polymerization, and then the latex is demulsified and dried.

[0062] In the third aspect of the present invention, a kind of preparation method of PE100 pipe compounding is provi...

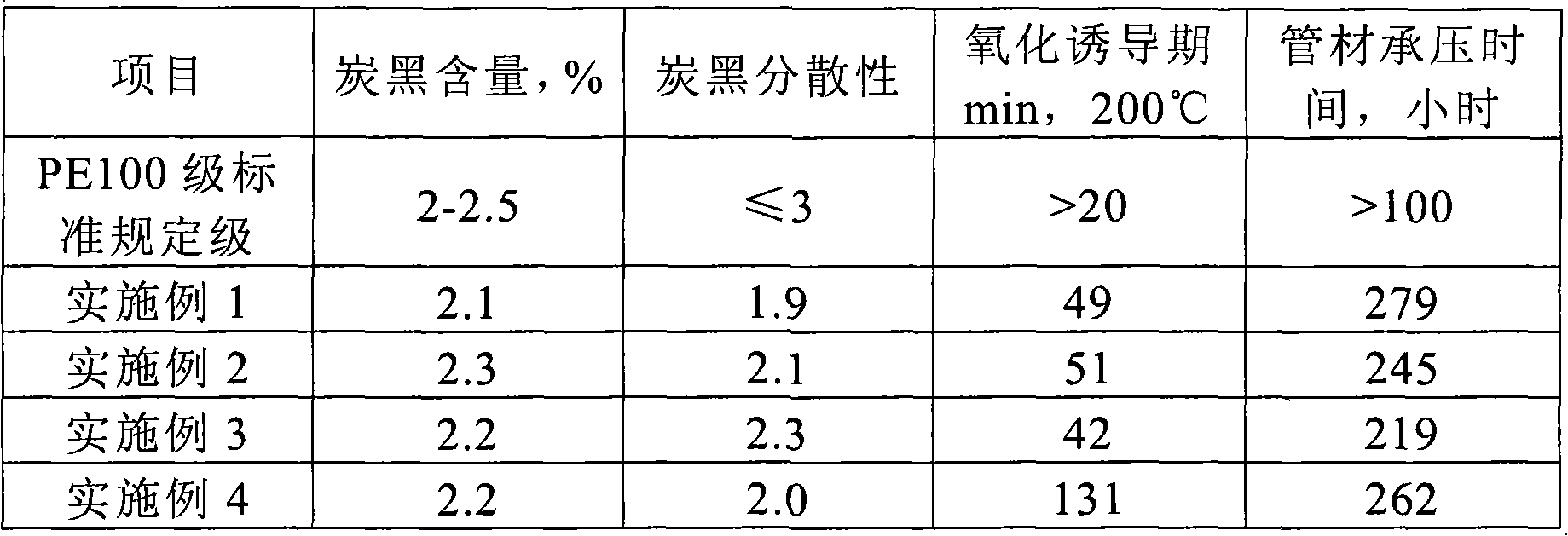

Embodiment 1

[0079] First put carbon black (brand: N110, average particle size 10-15nm, produced by Cabot Company) and styrene-butadiene pyridine copolymer (produced by Zibo Heli Chemical Co., Ltd.) into a continuous internal mixer, and process at 120°C 30 minutes, then add ultra-high molecular weight polyethylene resin (produced by Sinopec Qilu Petrochemical Co., Ltd.), antioxidant 1010 (produced by Ciba Specialty Chemicals in Switzerland), discharge and granulate after melt blending, to obtain the polymer compound of the present invention Carbon black masterbatch for vinyl pipes. Among them, 100 parts by weight of ultra-high molecular weight polyethylene, 30 parts by weight of carbon black, 1.75 parts by weight of butylfenene copolymer, and 0.2 parts by weight of antioxidant. After simple mechanical blending of high-density polyethylene pipe base material (brand YJH041, produced by Sinopec Shanghai Petrochemical Co., Ltd.) and the above-prepared color masterbatch in a high-speed mixer at...

Embodiment 2

[0081] The production process of the carbon black masterbatch for polyethylene pipes is the same as in Example 1. The specific formula of the color masterbatch is: 100 parts by weight of ultra-high molecular weight polyethylene, 50 parts by weight of carbon black, 10 parts by weight of styrene-butadiene pyridine copolymer, and 2 parts by weight of antioxidant. The production process of the pipe is the same as that of Example 1 except that the weight ratio of the high-density polyethylene pipe base material to the color masterbatch is changed to 100:8.

[0082] The specific performance test results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com