Light polylactic acid composite material and preparation method thereof

A technology of lightweight materials and composite materials, which is applied in the field of lightweight polylactic acid composite materials and its preparation, can solve the problems of low density, heat-resistant deformation temperature, high density of polylactic acid materials, and low thermal deformation temperature, etc., to achieve density reduction, The effect of good toughness and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

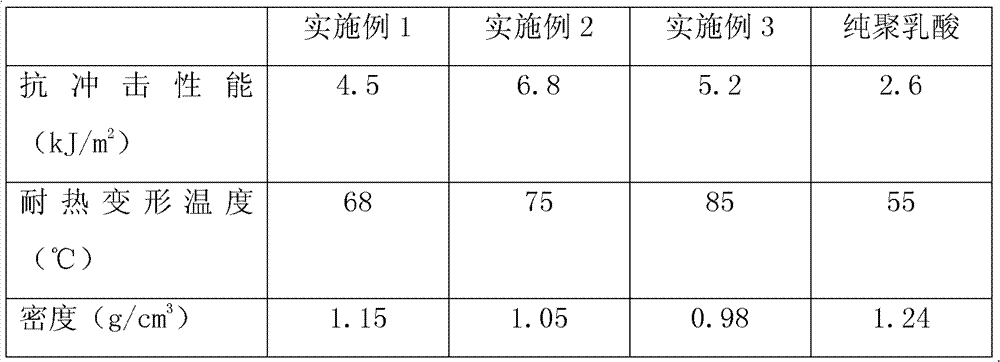

Examples

Embodiment 1

[0032] (1) The hollow glass microspheres were treated with a 0.1% silane coupling agent and dried in an air blast oven at 80°C.

[0033] (2) The polylactic acid and the toughening agent polybutylene succinate were vacuum-dried at 60° C. for 8 hours to remove moisture;

[0034] (3) the dried polylactic acid obtained in step (2) and the toughening agent polybutylene succinate and nano-montmorillonite, antioxidant tetrakis (β-(3,5 di-tert-butyl-4 -Hydroxyphenyl) propionate) pentaerythritol ester, etc. are stirred in a dry high-speed mixer according to a certain weight ratio to make it mix evenly, and then react in a twin-screw extruder, the screw speed is 25rpm, and the extrusion temperature is At 170°C, the hollow glass microspheres are fed into the screw extruder by side feeding, the product is cooled and pelletized, and dried in vacuum to obtain a toughened heat-resistant polylactic acid composite material masterbatch with reduced density; by weight ratio Total: wherein the c...

Embodiment 2

[0036] (1) Treat the phenolic microbeads with a silane coupling agent at a concentration of 0.5% and dry them in an air blast oven at 80°C.

[0037] (2) The polylactic acid and the polybutylene succinate grafted polylactic acid copolymer were vacuum-dried at 70° C. for 5 hours to remove moisture;

[0038] (3) the dried polylactic acid obtained in step (2) and the toughening agent polybutylene succinate grafted polylactic acid copolymer with nano-calcium carbonate, antioxidant (3,5-di-tert-butyl -4-Hydroxyphenyl) octadecyl propionate, etc. are stirred in a dry high-speed mixer according to a certain weight ratio to make it evenly mixed, and then reacted in a twin-screw extruder, the screw speed is 100rpm, extruded The temperature is 180°C, and the phenolic microbeads are fed into the screw extruder by side feeding. The product is cooled, pelletized, and vacuum-dried to obtain a toughened heat-resistant polylactic acid composite material masterbatch with reduced density; by weig...

Embodiment 3

[0040] (1) The hollow glass microspheres were treated with a silane coupling agent at a concentration of 1% and dried in a blast drying oven at 80°C.

[0041] (2) Polylactic acid and ethyl acrylate-butyl acrylate-acrylic acid copolymer were vacuum-dried at 80° C. for 2 hours to remove moisture;

[0042](3) the polylactic acid after the drying that step (2) obtains and toughening agent ethyl acrylate-butyl acrylate-acrylic acid copolymer and nano silicon dioxide, antioxidant β-(3,5-di-tert-butyl -4-Hydroxyphenyl) cyclohexyl propionate, etc. are stirred in a dry high-speed mixer according to a certain weight ratio to make it evenly mixed, and then react in a twin-screw extruder, the screw speed is 180rpm, extruded The temperature is 190°C, and the hollow glass microspheres are fed into the screw extruder by side feeding. The product is cooled, pelletized, and vacuum-dried to obtain a toughened heat-resistant polylactic acid composite masterbatch with reduced density; press In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com